Preparation method of fluorion adsorbent

An adsorbent and fluoride ion technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, silicate, etc., can solve the problems of low adsorption efficiency and high temperature of the adsorbent, and achieve low cost and high fluoride ion adsorption , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

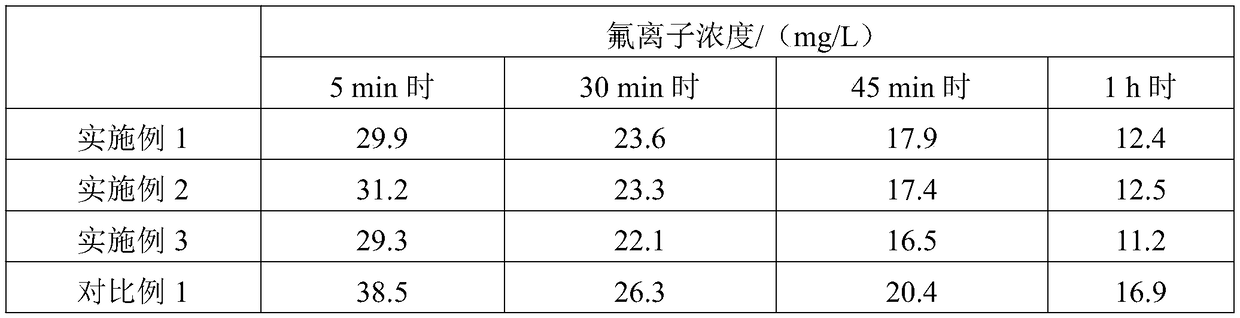

Examples

Embodiment 1

[0020] A preparation method of fluoride ion adsorbent, said preparation method comprising the following steps:

[0021] Step 1. Weigh 10 parts by mass of natural zeolite, then wash with deionized water until there is no suspended impurities, and bake at 100° C. for 10 min. The particle size of the natural zeolite is 1-1.5 mm.

[0022] Step 2. Put the baked natural zeolite into 120 parts by mass of 2wt.% Al 2 (SO 4 ) 3 Soak in the solution for 4 hours at a temperature of 70°C, then drop 5 parts by mass of 1mol / L NaOH solution into the soaking solution, stir for 10 minutes, then vacuum filter with a Buchner funnel, and roast the filtered modified zeolite at a temperature of 100°C 2h.

[0023] Step 3. Then add 1 mass part of kaolin, 2 mass parts of zirconium oxychloride and 0.5 mass part of bone char into the modified zeolite after roasting, and stir evenly.

[0024] Step 4. Add 60mL of 5wt.% acetic acid solution to the stirred mixture, add 12 parts by mass of 0.15mol / L ammon...

Embodiment 2

[0027] A preparation method of fluoride ion adsorbent, said preparation method comprising the following steps:

[0028] Step 1. Weigh 15 parts by mass of natural zeolite, then wash it with deionized water until there is no suspended impurities, and bake it at 120° C. for 20 minutes. The particle size of the natural zeolite is 1-1.5 mm.

[0029] Step 2. Put the baked natural zeolite into 150 parts by mass of 4wt.%Al 2 (SO 4 ) 3 Soak in the solution for 6 hours at 80°C, then add 8 parts by mass of 1mol / L NaOH solution dropwise to the soaking solution, stir for 20 minutes, then vacuum filter with a Buchner funnel, and roast the filtered modified zeolite at 120°C 4h.

[0030] Step 3. Then add 3 parts by mass of kaolin, 4 parts by mass of zirconium oxychloride and 1.2 parts by mass of bone char into the modified zeolite after roasting, and stir evenly.

[0031] Step 4. Add 80mL 5wt.% acetic acid solution to the stirred mixture, add 15 parts by mass of 0.15mol / L ammonium cerium ...

Embodiment 3

[0034] A preparation method of fluoride ion adsorbent, said preparation method comprising the following steps:

[0035] Step 1. Weigh 12 parts by mass of natural zeolite, then wash it with deionized water until there is no suspended impurities, and bake it at 110° C. for 15 minutes. The particle size of the natural zeolite is 1-1.5 mm.

[0036] Step 2. Put the baked natural zeolite into 130 parts by mass of 3wt.%Al 2 (SO 4 ) 3 Soak in the solution for 5 hours at a temperature of 75°C, then add 7 parts by mass of 1mol / L NaOH solution dropwise to the soaking liquid, stir for 15 minutes, and then vacuum-filter it with a Buchner funnel, and roast the filtered modified zeolite at a temperature of 110°C 3h.

[0037] Step 3. Then add 2 parts by mass of kaolin, 3 parts by mass of zirconium oxychloride and 1 part by mass of bone char into the modified zeolite after roasting, and stir evenly.

[0038] Step 4. Add 75mL 5wt.% acetic acid solution to the stirred mixture, add 13 parts b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com