Testing method for thermal conductivity of phase change energy storage material

A technology of phase-change energy storage materials and testing methods, which is applied in the field of phase-change energy storage materials, can solve problems such as dehydration, difficulty in accurate measurement, and difficulty in preparing samples to be tested, so as to ensure stability and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The purpose of this embodiment is to measure the CaCl in the cooling crystallization process. 2 ·6H 2 O at 29.2°C (i.e. the temperature to be measured T 0 ) at the thermal conductivity.

[0084] Specifically, the following steps are used for determination:

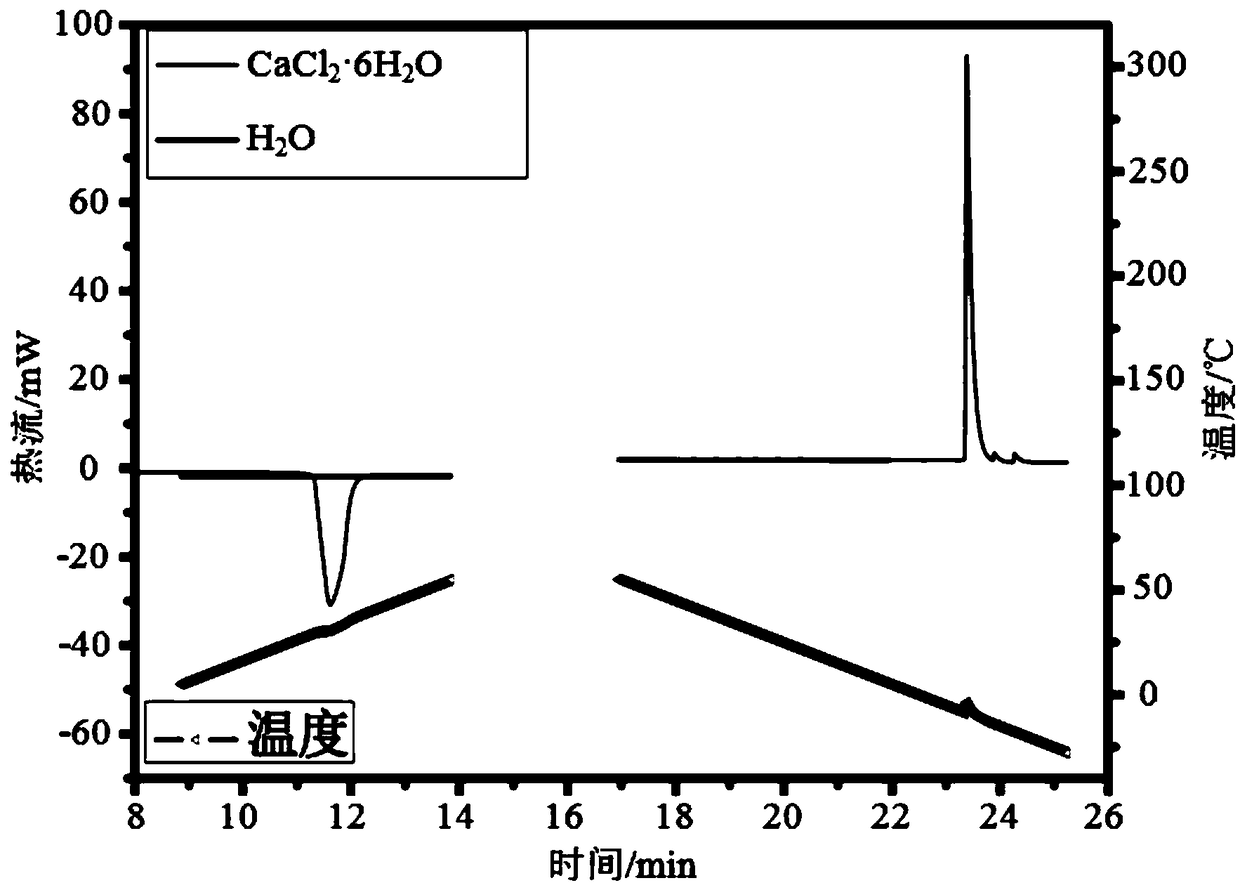

[0085] First, use DSC to test the empty sample pan (i.e. with a blank crucible as the background), water (m(H 2 O)=5.705mg) and CaCl 2 ·6H 2 O(m(Sam)=4.190mg) heat flow P(Bla), P(H 2 O) and P(Sam), the cooling rate is 10°C / min; the heat flow test results are as follows image 3 shown.

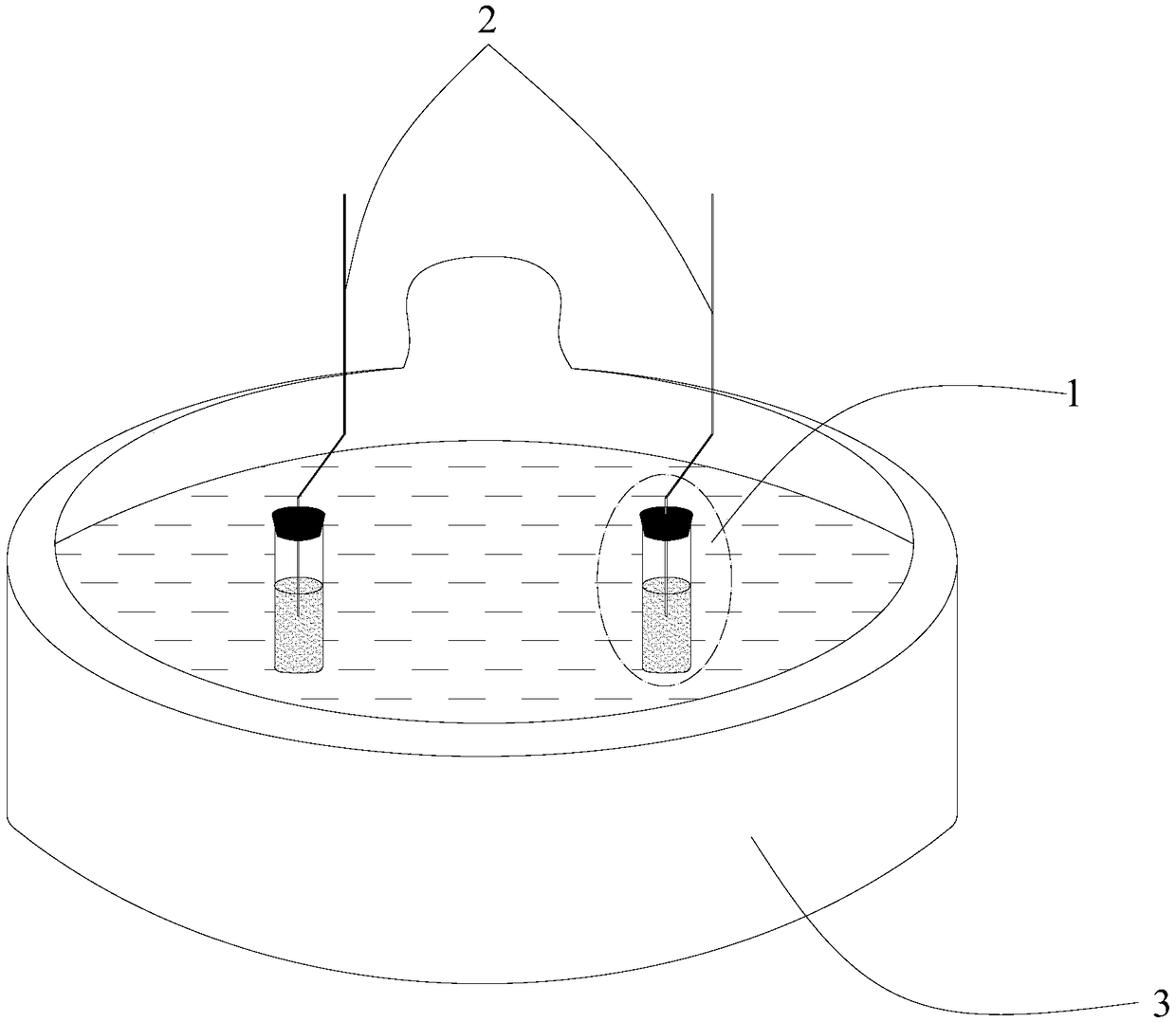

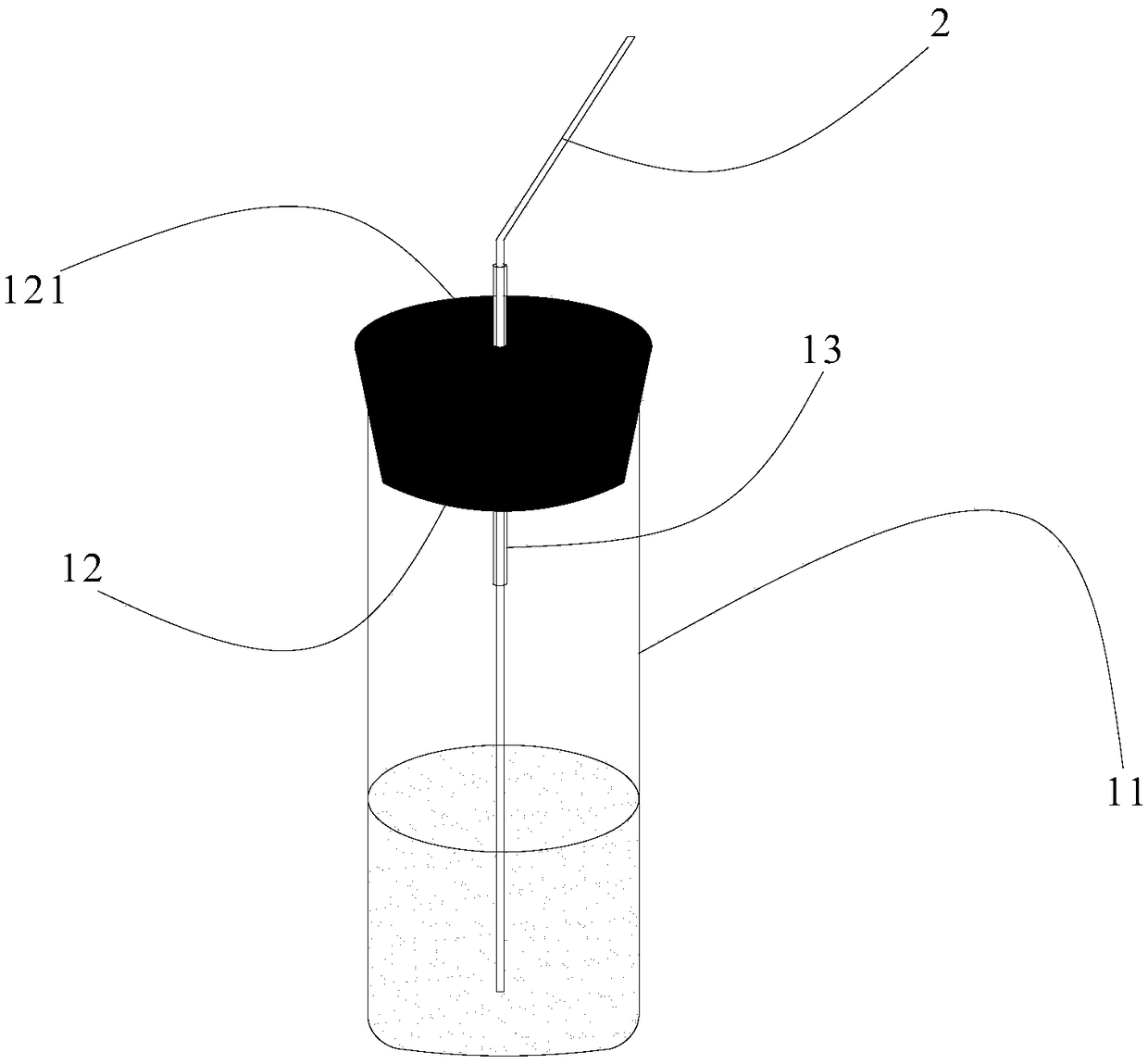

[0086] Then, 80mL of water (m'(H 2 O)=80.02g) and CaCl 2 ·6H 2 O(m'(Sam)=119.05g) were placed in figure 2 In the shown test tube 11, the test tube 11 is first placed in an ice-water bath, and shaken to make it crystallize at a temperature greater than 0°C (ice-water bath), CaCl 2 ·6H 2 Immediately after the O started to crystallize it was transferred to a 25 °C figure 1 In the water bath shown, and keep the water level...

Embodiment 2

[0091] The purpose of this embodiment is to measure the CaCl in the heating and melting process. 2 ·6H 2 O at 28.9°C (i.e. the temperature to be measured T 0 ) at the thermal conductivity.

[0092] Specifically, the following steps are used for determination:

[0093] First, use DSC to test the empty sample pan (i.e. with a blank crucible as the background), water (m(H 2 O)=5.705mg) and CaCl 2 ·6H 2 O(m(Sam)=4.190mg) heat flow P(Bla), P(H) heated between 30°C and 35°C 2 O) and P(Sam), the heating rate is 10°C / min; the heat flow test results are as follows image 3 shown.

[0094] Then, 80mL of water (m'(H 2 O)=80.02g) and CaCl 2 ·6H 2 O(m'(Sam)=119.05g) were placed in figure 2 In the test tube 11 shown, put the test tube 11 in a temperature of 35°C figure 1 In the water bath shown, and keep the water level line of the water bath and the water and CaCl in the test tube 2 ·6H 2 The surface of O is flat, water and CaCl are measured 2 ·6H 2 The temperature rise cu...

Embodiment 3

[0102] The purpose of this embodiment is to measure the CaCl in the heating process 2 ·6H 2 O liquid at 32.3 ℃ (that is, the temperature T to be measured 0 ) at the thermal conductivity.

[0103] Specifically, the following steps are used for determination:

[0104] First, use DSC to test the empty sample pan (i.e. with a blank crucible as the background), water (m(H 2 O)=5.705mg) and CaCl 2 ·6H 2 O(m(Sam)=7.590mg) heat flow P(Bla), P(H) heated between 29.5℃~35.0℃ 2 O) and P(Sam), the heating rate is 5°C / min; the heat flow test results are as follows Figure 5 and Image 6 shown. from Figure 5 and Image 6 It can be known that P(H 2 O)-P(Bla)=-1.863mW, P(Sam)-P(Bla)=-1.411mW; and it can be known from Example 2 that CaCl 2 ·6H 2 The average phase transition temperature of O in the heating process is 28.95°C, thus, the temperature T to be measured in this embodiment 0 With the sample to be tested CaCl 2 ·6H 2 The phase transition temperature T(Sam) of O is incon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com