Instant green konjac tofu and making method thereof

A konjac tofu and green technology, applied in food ingredients as color, food science, food preservation, etc., can solve the problems of unfavorable taste of ready-to-eat products, affect the gelation of konjac tofu, and reduce the elasticity of konjac tofu, so as to enrich product types and taste More chewy, even texture and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Refined fresh konjac

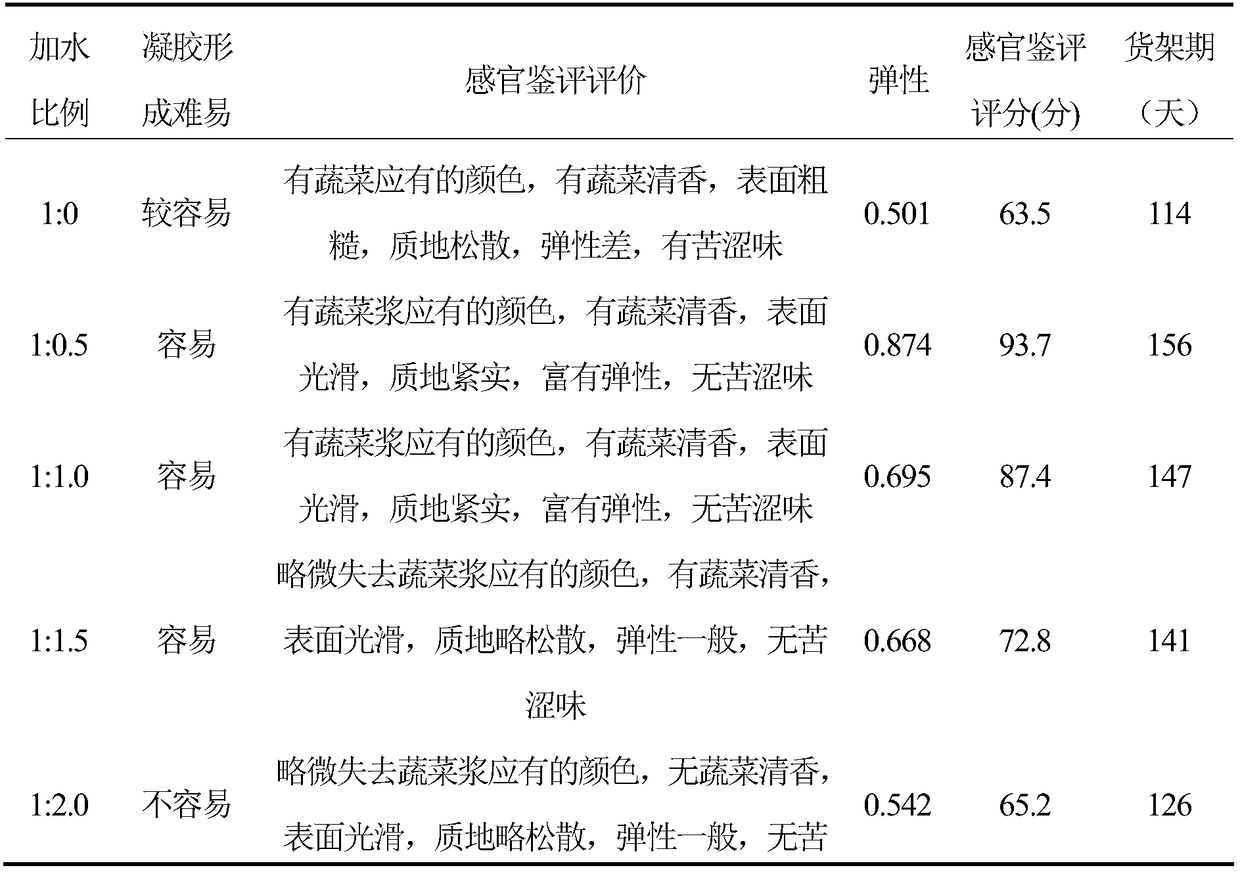

[0025] Take fresh konjac with a smooth surface and no wormholes, remove the root fibers and terminal buds on the surface, clean the whole body of konjac, peel off the skin by mechanical friction, and mix and refine the pulp according to the mass ratio of fresh konjac and water at 1:0.5.

[0026] 2. Enzymolysis

[0027] Add 60g of α-amylase and 30g of glucoamylase to 10kg of konjac pulp, and perform enzymatic hydrolysis at 68°C for 3h.

[0028] 3. Ingredients

[0029] Keep the enzymatically hydrolyzed konjac pulp in a slightly boiling state, then add 80g of food-grade soda ash, 2g of a mixture of sucralose and xylitol in a mass ratio of 1:200, and 300g of xanthan gum and locust bean gum in a mass ratio of 1:1 The mixture was stirred for 1 min, then 1.4kg of spinach pulp was added, and the stirring was stopped when a viscous paste appeared, wherein the spinach pulp was obtained by beating spinach with water at a mass ratio of 1:1.

[0030] 4. ...

Embodiment 2

[0035] In step 3 of the present embodiment, the konjac pulp after enzymolysis is kept in a slightly boiling state, and then 100g of food-grade soda ash, 2g of sucralose and xylitol are added in a mass ratio of 1:200, 300g of xanthan gum and black locust A mixture with a mass ratio of bean gum of 1:1 was stirred for 1 min, then 2.1 kg of celery pulp was added, and the stirring was stopped when a viscous paste appeared. The celery pulp was obtained by beating celery with water at a mass ratio of 1:0.5. Other steps are identical with embodiment 1, obtain instant green konjac tofu.

Embodiment 3

[0037] In step 3 of the present embodiment, the konjac pulp after enzymolysis is kept in a slightly boiling state, and then 80g of food-grade soda ash, 2g of sucralose and xylitol are added in a mass ratio of 1:200, 300g of xanthan gum and black locust A mixture of bean gum with a mass ratio of 1:1 was stirred for 1 min, then 2.1 kg of cabbage pulp was added, and the stirring was stopped when a viscous paste appeared. The cabbage pulp was obtained by beating cabbage with water at a mass ratio of 1:0.5. Other steps are identical with embodiment 1, obtain instant green konjac tofu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com