Conductive slurry seal material and preparation method and paving technology thereof

A slurry sealing layer and process technology, which is applied in the field of conductive slurry sealing layer materials and its preparation, can solve the problems of being difficult to apply to existing road surfaces, low thermal efficiency, complicated construction, etc., to achieve resource conservation, improve heating efficiency, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

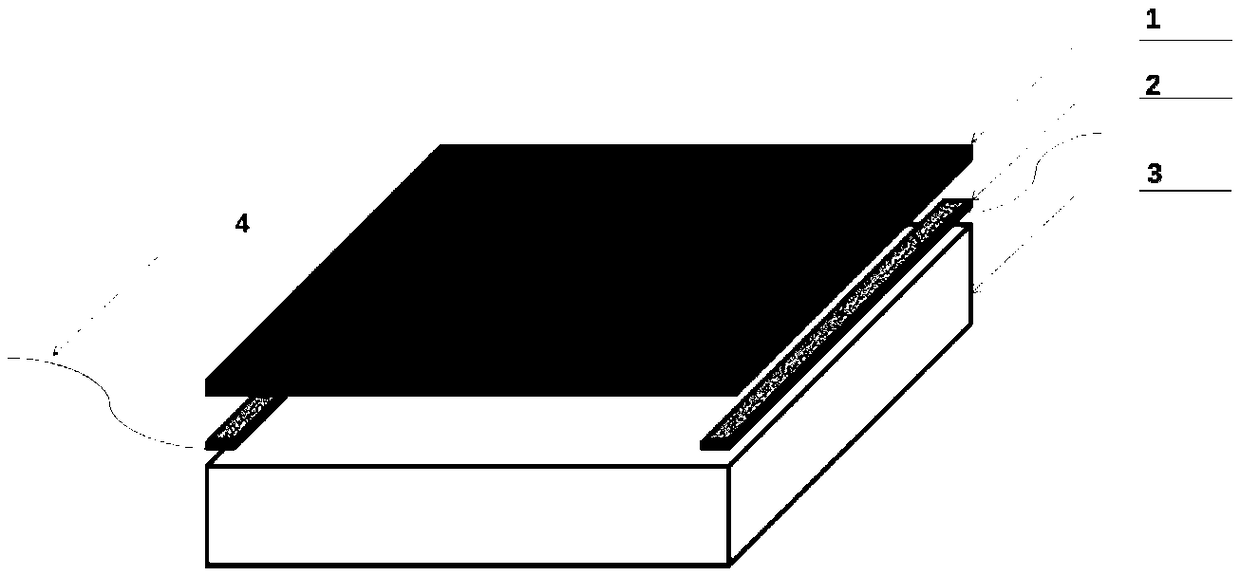

Image

Examples

Embodiment 1

[0061] A conductive slurry sealing layer material, its components and the mass percentage ratio of each component are as follows:

[0062] 2000 mesh graphite powder: 2mm chopped carbon fiber: water-based epoxy resin A: water-based epoxy resin B: emulsified asphalt: cement: water: particle diameter is 3mm black corundum aggregate=4%: 0.5%: 3%: 3% : 4% : 0.5% : 2% : 83%.

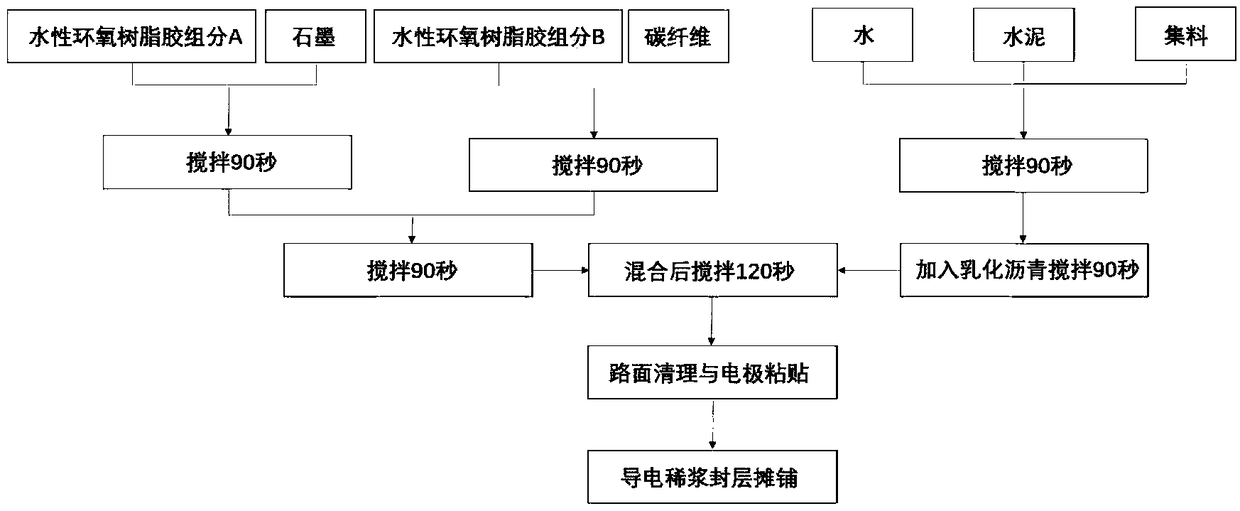

[0063] The preparation of the conductive slurry sealing material of the present embodiment comprises the following steps:

[0064] (1) First take 8g of 2000 mesh graphite powder and add it into 6g of water-based epoxy resin A component and fully stir for 90 seconds;

[0065] (2) Then add 1g of 2mm chopped carbon fiber into 6g of water-based epoxy resin component B and fully stir for 90 seconds;

[0066] (3) Next, add 1g of cement to 166g of black corundum aggregates with a particle size of 3mm, add 4g of water and then stir quickly for 90 seconds to make the surface of the cement and aggregate fully wet and ...

Embodiment 2

[0088] A conductive slurry sealing layer material, its components and the mass percentage ratio of each component are as follows:

[0089] 2000 mesh graphite powder: 2mm chopped carbon fiber: water-based epoxy resin A: water-based epoxy resin B: emulsified asphalt: cement: water: particle size is 3mm limestone aggregate = 5%: 1%: 3%:: 3%: 4%: 0.5%: 2%: 81.5%

[0090] The preparation method of the conductive slurry sealing layer material of the present embodiment comprises the following steps:

[0091] (1) First take 10g of graphite powder and add it to 6g of water-based epoxy resin component A and fully stir for 90 seconds;

[0092] (2) Then add 2g of 2mm chopped carbon fiber into 6g of water-based epoxy resin component B and fully stir for 90 seconds;

[0093] (3) Next, add 1g of cement to 163g of limestone aggregate with a particle size of 3mm, add 4g and then stir rapidly for 90 seconds to make the surface of cement and aggregate fully wet and evenly dispersed, then add 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com