Delay water absorption expansion leakage blocking agent and preparation method thereof

A water-absorbing expansion and plugging agent technology, which is applied in the field of plugging aids, can solve the problems of reduced swelling performance and achieve the effects of delaying expansion, enhancing plugging strength, and improving pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

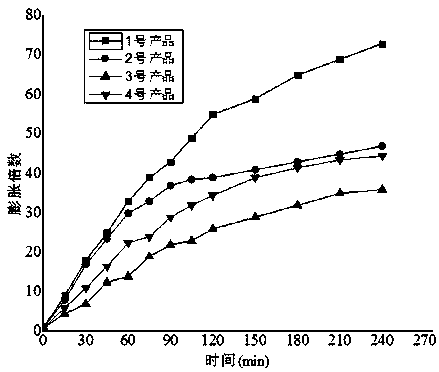

Embodiment 1

[0020] First weigh 40g of acrylamide, 20g of 2-acrylamido-2-methylpropanesulfonic acid, 0.08g of N,N-methylenebisacrylamide and 0.04g of initiator ammonium persulfate into the reactor, add 300g of distilled water, Stir in an ice-water bath until completely dissolved, pass N 2 Protection; when the temperature drops to about 2°C, slowly add 30g of initiator sodium sulfite solution (sodium sulfite 0.04g) dropwise; after dropping, continue to stir for 15min, stop stirring, slowly raise the temperature to 50°C, and statically react for 3h to obtain an elastic gel body; it was taken out, vacuum-dried at 70°C, and sheared to obtain the No. 1 product of water-absorbing swelling plugging agent without hydrophobic modification.

Embodiment 2

[0022] First weigh 50g of acrylamide, 25g of 2-acrylamido-2-methylpropanesulfonic acid, 0.08g of N,N-methylenebisacrylamide and 0.04g of initiator ammonium persulfate into the reactor, add 350g of distilled water, Stir in an ice-water bath until completely dissolved; slowly add 6g of enhancer sodium bentonite and 5g of hydrophobic monomer 2-acrylamide sodium dodecylsulfonate, continue to stir at low temperature evenly, pass N 2 Protection; when the temperature drops to about 2°C, slowly add 30g of initiator sodium sulfite solution (sodium sulfite 0.04g) dropwise; after dropping, continue to stir for 15min, stop stirring, slowly raise the temperature to 50°C, and statically react for 3h to obtain an elastic gel body; it was taken out, vacuum-dried at 70°C, and sheared to obtain the No. 2 product of delayed water-swelling plugging agent.

Embodiment 3

[0024] First weigh 40g of acrylamide, 25g of 2-acrylamido-2-methylpropanesulfonic acid, 0.06g of N,N-methylenebisacrylamide and 0.03g of initiator sodium persulfate into the reactor, add 350g of distilled water, Stir in an ice-water bath until completely dissolved; slowly add 3g of enhancer kaolin and 2g of hydrophobic monomer octadecyltrimethylammonium chloride, continue to stir at low temperature evenly, pass N 2 Protection; when the temperature drops to about 2°C, slowly add 30g of initiator sodium sulfite solution (sodium sulfite 0.03g) dropwise; after dropping, continue to stir for 15min, stop stirring, slowly raise the temperature to 50°C, and statically react for 3h to obtain an elastic gel body; it was taken out, vacuum-dried at 70°C, and sheared to obtain the No. 3 product of delayed water-swelling plugging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com