Preparation method of polyethylene composition for bottle cap

A technology of polyethylene and composition, applied in the field of preparation of polyethylene composition, to achieve the effects of accelerated dissolution, wide application range, and favorable promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

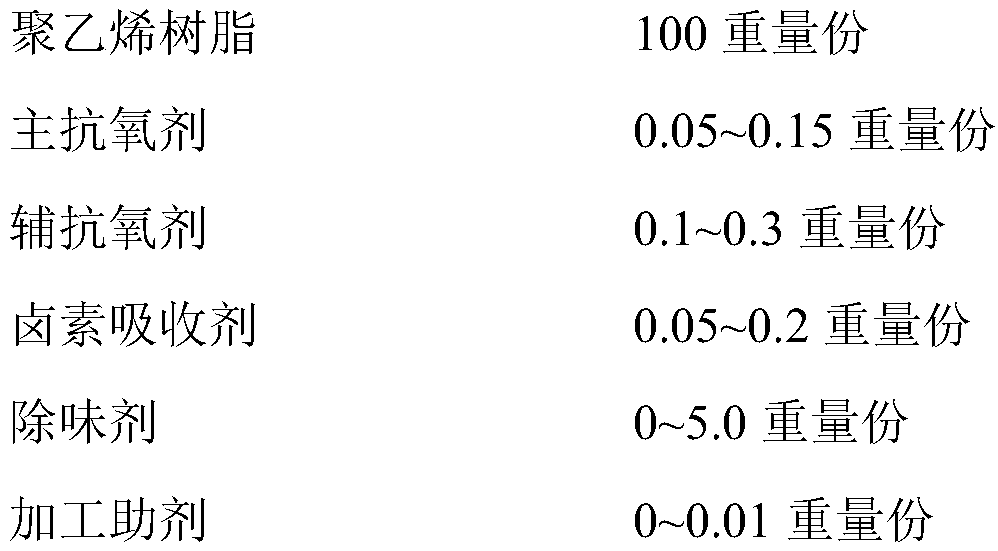

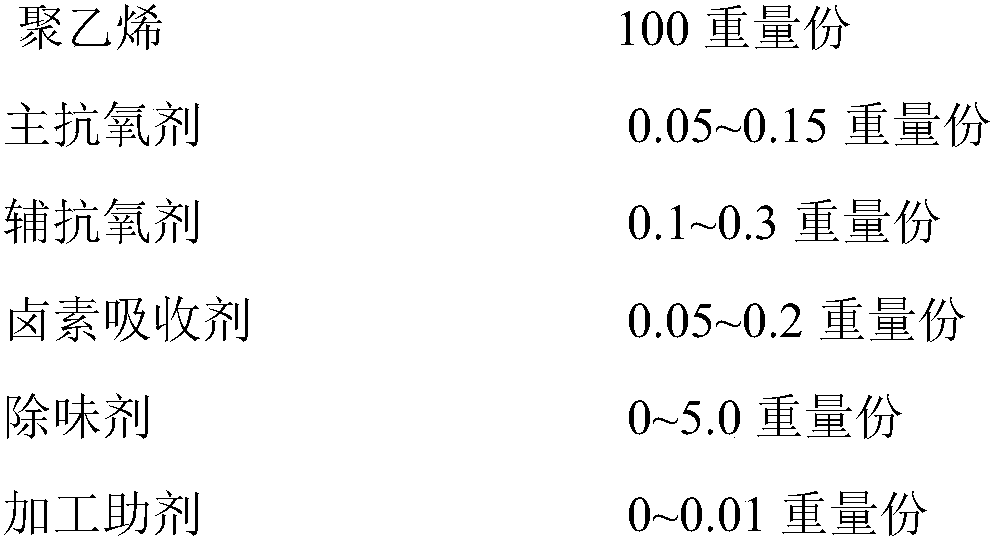

Method used

Image

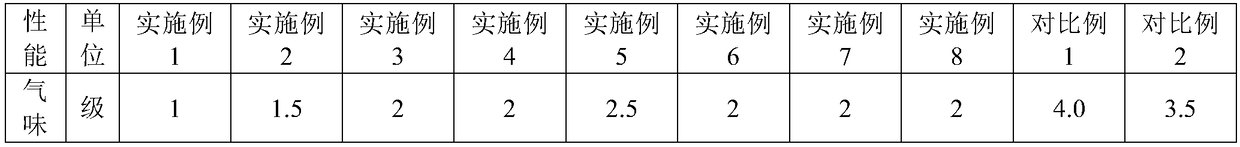

Examples

Embodiment 1

[0042] Weigh 50kg polyethylene powder (density 0.955g / cm 3 , melt flow rate 0.5g / 10min), 25g antioxidant 1010, 50g antioxidant 168, 25g halogen absorbent calcium stearate, 500 grams of medical stone (particle size 2500 mesh), after fully mixing by stirring, add A twin-screw extruder with a length-to-diameter ratio of L / D of 48:1, a feed rate of 50 g / min, and a screw speed of 100 rpm; supercritical carbon dioxide fluid is added to the extruder from the second heating zone of the twin-screw extruder. Out of the machine, the quality of the supercritical carbon dioxide fluid is 20% of the polyethylene quality, and the adding speed is 10g / min. The twin-screw extruder is divided into 10 heating zones, the temperature of the first heating zone is 180°C, and the temperature of the other heating zones is 160°C-200°C. Vacuum devolatilize in the 8th area, extrude the granulated material strips to obtain the product through water-cooling and pelletizing.

Embodiment 2

[0044] Weigh 50kg polyethylene powder (density 0.956g / cm 3 , melt flow rate 1.5g / 10min), 50g antioxidant 1010, 100g antioxidant 168, 25g halogen absorbent calcium stearate, 1500 grams of medical stone (particle size 2500 mesh), 25 grams of fluoroelastomer, after After stirring and mixing fully, add the twin-screw extruder whose length-to-diameter ratio L / D is 48:1, the feeding speed is 50g / min, and the screw speed is 100 rpm; The second heating zone is added to the extruder, the quality of the supercritical carbon dioxide fluid is 10% of the polyethylene mass, and the feeding speed is 5g / min. The twin-screw extruder is divided into 10 heating zones, the temperature of the first heating zone is 180°C, and the temperature of the other heating zones is 160°C-200°C. In the 8th heating zone, the product is vacuumized and devolatilized, extruded and granulated, and then water-cooled and granulated to obtain the product.

Embodiment 3

[0046] Weigh 50kg polyethylene powder (density 0.955g / cm 3 , melt flow rate 2.5g / 10min), 75g antioxidant 1076, 100g antioxidant 168, 50g halogen absorbent calcium stearate, 2500 grams of medical stone (particle size 2500 mesh), 50 grams of fluoroelastomer, after After stirring and mixing fully, add the twin-screw extruder whose length-to-diameter ratio L / D is 48:1, the feeding speed is 50g / min, and the screw speed is 100 rpm; The second heating zone is added to the extruder, the quality of the supercritical carbon dioxide fluid is 30% of the polyethylene mass, and the feeding speed is 15g / min. The twin-screw extruder is divided into 10 heating zones, the temperature of the first heating zone is 180°C, and the temperature of the other heating zones is 160°C-210°C. In the 8th heating zone, the product is vacuumized and devolatilized, extruded and granulated, and then water-cooled and granulated to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com