Environment-friendly wind driven generator synthetic ester gear oil and preparation method thereof

A kind of wind power generator, environment-friendly technology, applied in the field of lubricating oil, can solve the problems of unable to form a strong oil film on the tooth surface, unable to achieve long-life oil use, insufficient protection of the gearbox, etc., to achieve improved micropitting resistance, The effect of good thermal and oxidation stability, excellent anti-wear and bearing protection properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

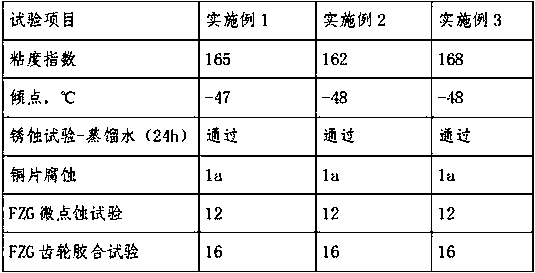

Examples

Embodiment 1

[0022] An environment-friendly synthetic ester gear oil for wind power generators, consisting of the following components in parts by weight:

[0023] 32 parts of metallocene PAO150 base oil, 23 parts of cyclohexane dicarboxylate, 23.9 parts of alkyl naphthalene,

[0024] 1.0 parts of aromatic amine antioxidant, 1.2 parts of viscosity index improver, 2.0 parts of ashless composite extreme pressure antiwear agent

[0025] 1.2 parts of repairing friction modifier, 1.0 part of anti-emulsifier, 1.3 parts of anti-rust and anti-corrosion agent;

[0026] Specifically, the aromatic amine antioxidant is dialkyl diphenylamine;

[0027] Specifically, the viscosity index improver is polyalkylmethacrylate;

[0028] Specifically, the ashless composite extreme pressure antiwear agent is tricresyl phosphate (T306), aryl phosphate, and a mixture of the two;

[0029] Specifically, the repair type friction modifier is a nano-boride rare earth friction modifier;

[0030] Specifically, the ant...

Embodiment 2

[0037] An environment-friendly synthetic ester gear oil for wind power generators, consisting of the following components in parts by weight:

[0038] 30 parts of metallocene PAO150 base oil, 20 parts of cyclohexane dicarboxylate, 20 parts of alkyl naphthalene,

[0039] 0.6 parts of aromatic amine antioxidant, 1 part of viscosity index improver, 1.5 parts of ashless composite extreme pressure antiwear agent

[0040] 1.0 parts of repairing friction modifier, 0.8 parts of anti-emulsifier, 1.2 parts of anti-rust and anti-corrosion agent;

[0041] Specifically, the aromatic amine antioxidant is N-phenyl-α-aniline;

[0042] Specifically, the viscosity index improver is polyalkylmethacrylate;

[0043] Specifically, the ashless composite extreme pressure antiwear agent is a mixture of aryl phosphate and alkyl polysulfide;

[0044] Specifically, the repair type friction modifier is a nano-boride rare earth friction modifier;

[0045] Specifically, the anti-emulsifying agent is a p...

Embodiment 3

[0052] An environment-friendly synthetic ester gear oil for wind power generators, consisting of the following components in parts by weight:

[0053] 35 parts of metallocene PAO150 base oil, 25 parts of cyclohexane dicarboxylate, 25 parts of alkyl naphthalene,

[0054] 1.5 parts of aromatic amine antioxidant, .5 parts of viscosity index improver, 2.5 parts of ashless composite extreme pressure antiwear agent

[0055] 1.5 parts of repairing friction modifier, 1.2 parts of anti-emulsifier, 1.5 parts of anti-rust and anti-corrosion agent;

[0056] Specifically, the aromatic amine antioxidant is a mixture of dialkyl diphenylamine and N-phenyl-α-aniline;

[0057] Specifically, the viscosity index improver is polyalkylmethacrylate;

[0058] Specifically, the ashless composite extreme pressure antiwear agent is a mixture of tricresyl phosphate (T306), aryl phosphate, and alkyl polysulfide;

[0059] Specifically, the repair type friction modifier is a nano-boride rare earth fricti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com