Low-nitrogen gas burner with adjustable and self-circulation exhaust gas in furnace

A gas burner and adjustable technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of large floor space, high investment, power loss, etc., achieve a high degree of combustion completeness, and reduce equipment investment. , the effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

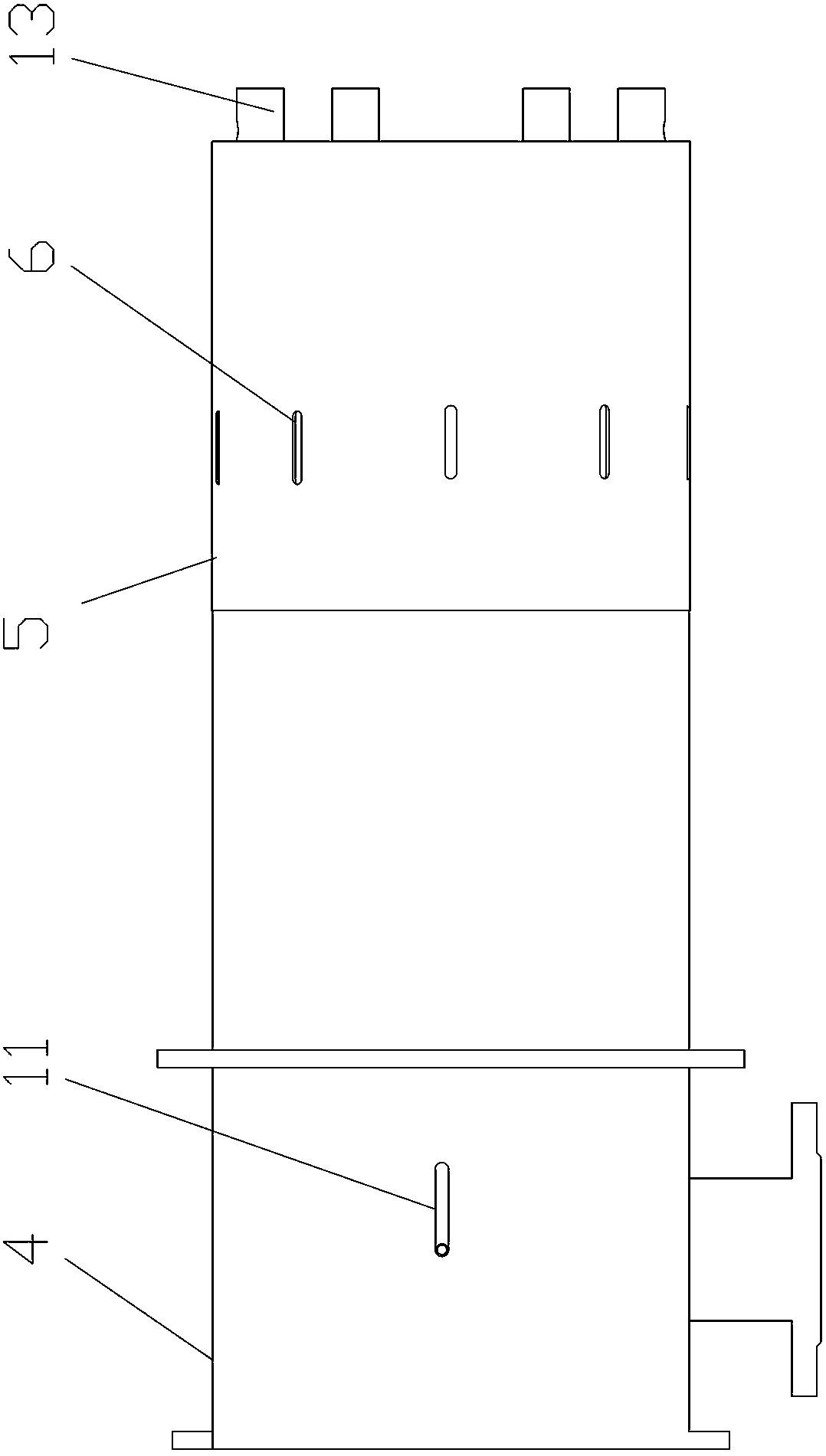

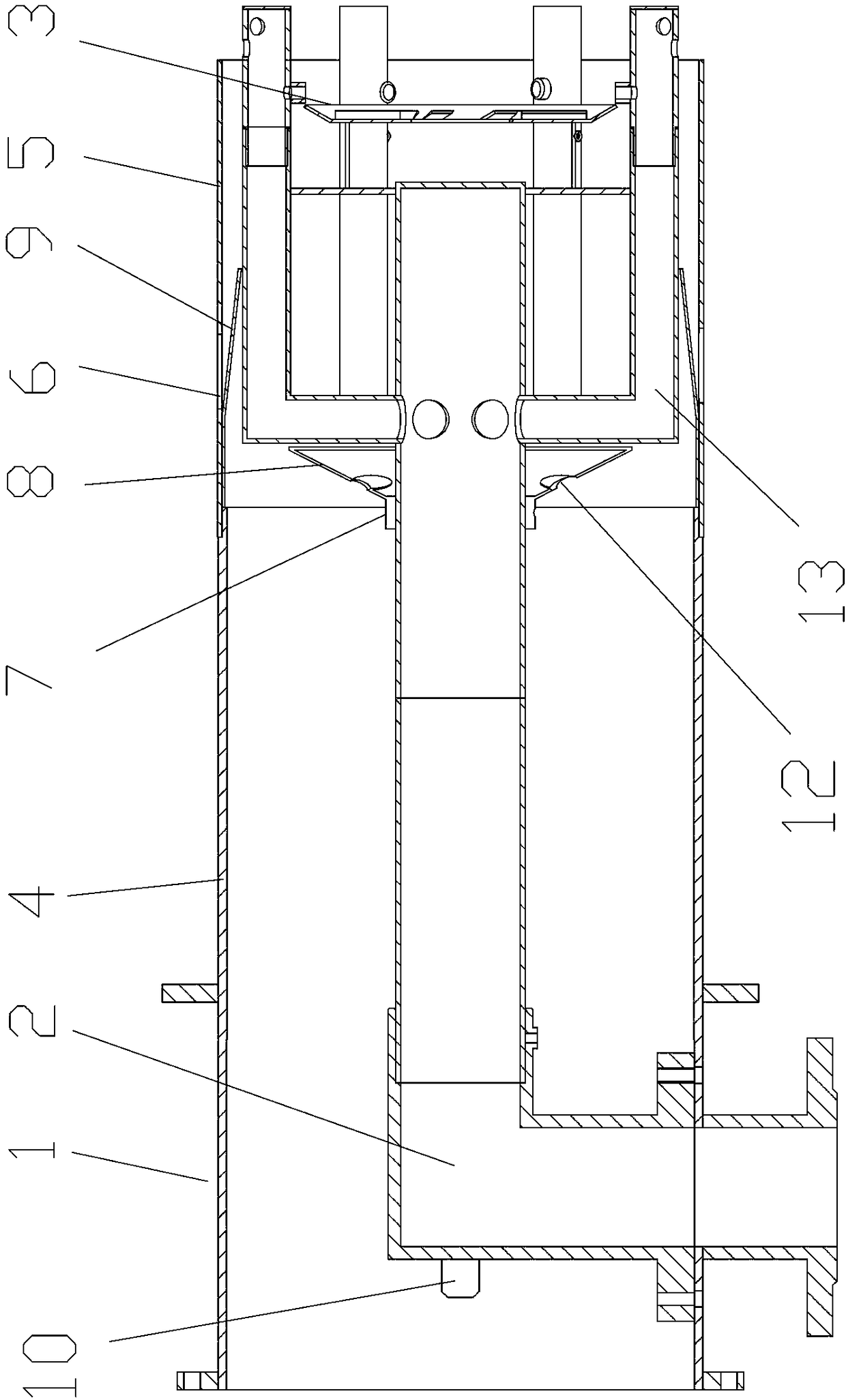

[0024] Now in conjunction with accompanying drawing, the present invention will be further described:

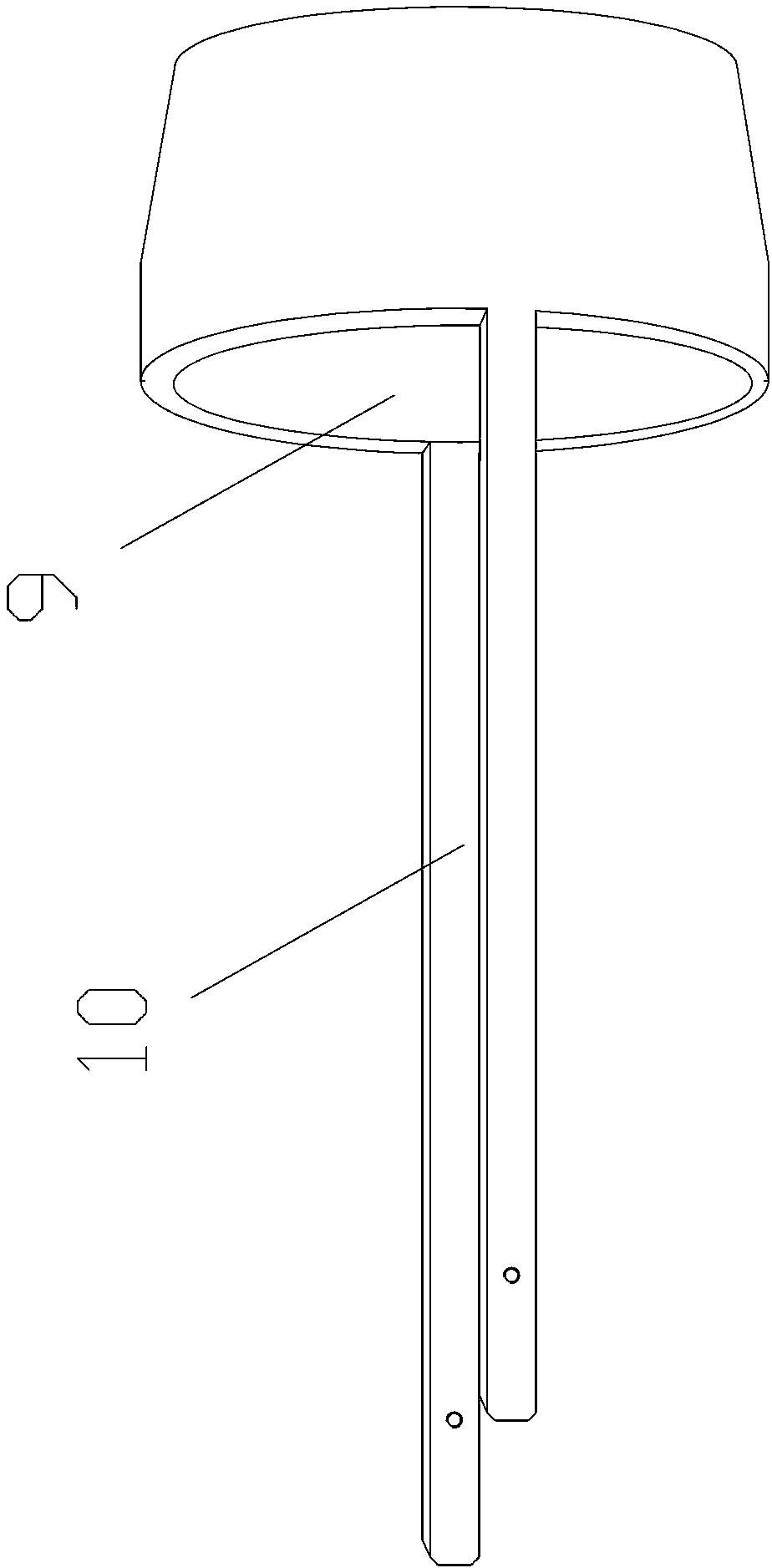

[0025] refer to figure 1 and figure 2 , a furnace flue gas adjustable self-circulation low-nitrogen gas burner described in this embodiment includes a combustion tube 1, the combustion tube 1 has an axial air inlet, a radial gas inlet and an axial outlet, and the combustion tube 1 is coaxially provided with a gas pipe 2 connected to the radial gas inlet, and an ignition device (not shown in the figure) and a flame stabilizing plate 3 are provided at the axial outlet. The gas pipe 2 extends evenly around the circumferential wall with a plurality of horizontal L-shaped shunt pipes 13, and each shunt pipe 13 is provided with a radially inward gas outlet and a radially outward gas outlet. The gas is transported axially in the gas pipe 2, and is guided radially outward in the middle section into each branch pipe 13 to be evenly dispersed into multiple gas streams, and then con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com