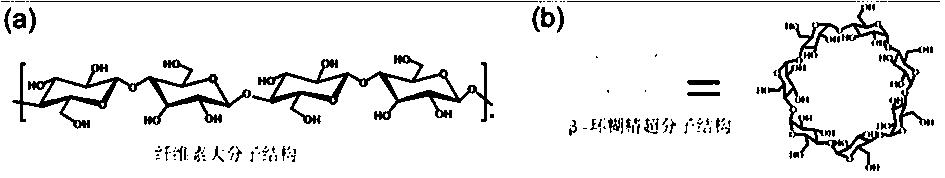

Magnetic cellulose/beta-cyclodextrin medicinal control-release hydrogel ball and preparation method thereof

A technology of cellulose and cyclodextrin, which is applied in drug delivery, pharmaceutical formula, capsule delivery, etc., to achieve broad application prospects, large-scale production, and convenient and controllable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing magnetic cellulose / beta-cyclodextrin drug controlled release hydrogel balls, the specific steps are:

[0032] (1) Add 2.0 cotton linter fiber raw materials into 98g lithium hydroxide-urea-water cellulose dissolving system, stir rapidly to form a homogeneous cellulose solution;

[0033] (2) Take 2.0g of β-cyclodextrin and add it to the homogeneous cellulose solution, then add 2ml of epichlorohydrin cross-linking agent, and stir rapidly for 40 minutes to make it fully react so that β-cyclodextrin is grafted onto the On the cellulose macromolecular skeleton; then add 0.5g of Fe 3 o 4 For magnetic nanoparticles, after fully stirring and dispersing for 30 min, slowly drop the mixed solution into ethanol aqueous solution (50wt%) to obtain spherical magnetic cellulose / β-cyclodextrin hydrogel, which is washed and purified to obtain the finished product.

Embodiment 2

[0035] A method for preparing magnetic cellulose / beta-cyclodextrin drug controlled release hydrogel balls, the specific steps are:

[0036] (1) Add 3.0 microcrystalline cellulose fiber raw materials into 97g sodium hydroxide-urea-water cellulose dissolution system, and stir rapidly to form a homogeneous cellulose solution;

[0037] (2) Take 3.0g of β-cyclodextrin and add it to the homogeneous cellulose solution, then add 3ml of epichlorohydrin crosslinking agent, and stir rapidly for 40 minutes to make it fully react and graft β-cyclodextrin to the On the skeleton of cellulose macromolecules. Then add 1.5g of Fe 3 o 4 For magnetic nanoparticles, after fully stirring and dispersing for 30 min, slowly drop the mixed solution into methanol aqueous solution (50wt%) to obtain spherical magnetic cellulose / β-cyclodextrin hydrogel, which is washed and purified to obtain the finished product.

Embodiment 3

[0039] A method for preparing magnetic cellulose / beta-cyclodextrin drug controlled release hydrogel balls, the specific steps are:

[0040] (1) Add 4.0 pulp fiber raw materials into 96g sodium hydroxide-urea-water cellulose dissolving system, stir rapidly to form a homogeneous cellulose solution;

[0041] (2) Take 4.0g of β-cyclodextrin and add it to the homogeneous cellulose solution, then add 4ml of epichlorohydrin cross-linking agent, and stir rapidly for 40 minutes to make it fully react so that β-cyclodextrin is grafted onto the On the skeleton of cellulose macromolecules. Then add 0.5g of Fe 3 o 4 For magnetic nanoparticles, after fully stirring and dispersing for 30 minutes, slowly drop the mixed solution into 10% potassium chloride aqueous solution to obtain spherical magnetic cellulose / β-cyclodextrin hydrogel, which is washed and purified to obtain the finished product.

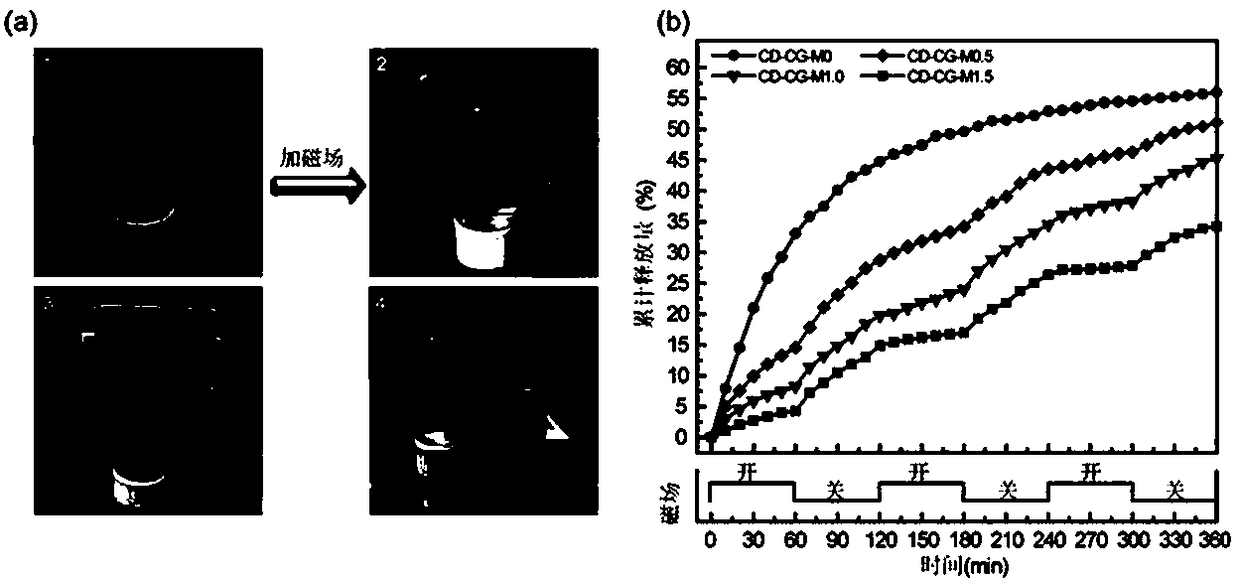

[0042] Practical application:

[0043] (1) Place the composite hydrogel sphere in 1 mg / ml 5-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com