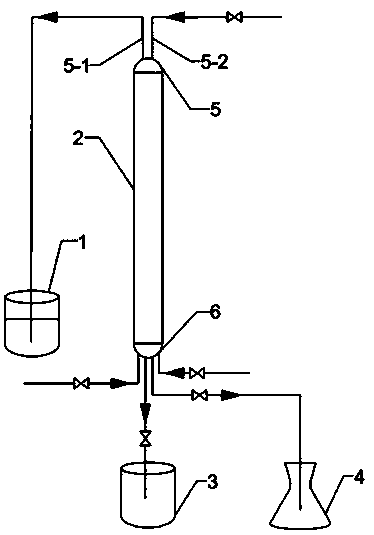

Continuous HMDS (hexamethyldisilazane) producing reaction system with enhanced mass transfer and flow and method

A reaction system and reaction tube technology, applied in the field of chemical plants, can solve the problems of low heat transfer and mass transfer efficiency, affecting fluid flow and mass transfer, and long reaction time, so as to improve production efficiency and strengthen fluid mass transfer and flow , good continuous and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

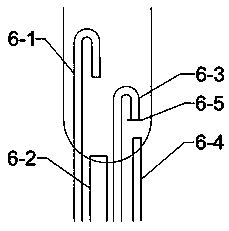

[0031] Before the reaction starts, the reaction tube 2 is filled with the solvent HMDO, the ammonia gas is fed through the ammonia gas feed pipe (6-1), the flow rate is 50ml / min, and the volume ratio of the liquid feed pipe (5-2) is The 1:5 mixture of TMS and HMDO, the flow rate is 1.2 ml / min, the nitrogen gas stirring tube (6-4) is injected with an appropriate amount of nitrogen gas to stir, and the reaction starts, and the crystals formed by the reaction gradually precipitate and accumulate in the lower tube part 6 of the reactor Afterwards, the valves are opened successively by NH 4 The Cl solid discharge pipe (6-2) is discharged into the solid collection device 3, and the liquid level in the reaction pipe 2 is kept stable, and passes through the filter screen (6-4), and the clarified liquid after the reaction is discharged from the liquid discharge pipe (6-3 ) into the liquid collection device, during the reaction, the three phases of gas, liquid and solid can be smoothly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com