Preparation method and application of boron nitride loaded Ni-MoOx nano catalyst

A nano-catalyst, boron nitride technology, applied in the field of catalyst preparation and sustainable development of the environment and energy, can solve the problems that limit the large-scale practical application of noble metal-based catalysts, low catalyst utilization, high cost, etc., achieve short synthesis time, Reduced crystallinity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

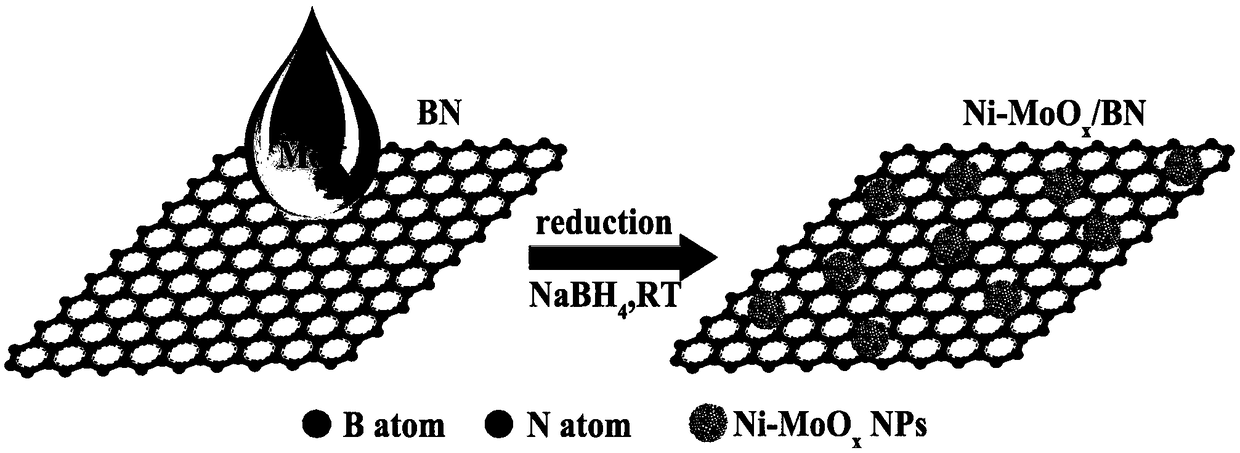

[0029] Such as figure 1 As shown, a boron nitride supported Ni-MoO x The preparation method of nanometer catalyst comprises the following steps:

[0030] Step 1. Prepare 15 mg of an aqueous solution of hexagonal boron nitride BN with a concentration of 0.5 to 6 mg / mL, and obtain a uniformly dispersed hexagonal boron nitride BN aqueous solution after ultrasonic treatment for 15 to 120 minutes;

[0031] Step two, the NiCl of 0.1mmol 2 , added to the BN aqueous solution in step 1, and continued to stir for 1 to 10 minutes to obtain a mixed solution A;

[0032] Step 3, then 0.1mmol of Na 2 MoO 4 Add to the mixed solution A in step 2, and continue to stir to obtain the mixed solution B; and the molar ratio of Ni:Mo is 1:1;

[0033] Step four, 30mg sodium borohydride NaBH 4Dissolve in 1mL of distilled water, add as a reducing agent to the mixed solution B in step 3, stir at 25°C for 5-15min for reduction reaction, and obtain boron nitride-supported Ni-MoO x nanocatalyst.

[...

Embodiment 2

[0036] A Boron Nitride Supported Ni-MoO x The preparation method of nanometer catalyst comprises the following steps:

[0037] Step 1. Prepare 15 mg of an aqueous solution of hexagonal boron nitride BN with a concentration of 0.5 to 6 mg / mL, and obtain a uniformly dispersed hexagonal boron nitride BN aqueous solution after ultrasonic treatment for 15 to 120 minutes;

[0038] Step two, the NiCl of 0.05mmol 2 Add the aqueous solution to the BN aqueous solution in step 1, and continue to stir for 1 to 10 minutes to obtain the mixed solution A;

[0039] Step 3, then 0.05mmolNa 2 MoO 4 Add the aqueous solution to the mixed solution A in step 2, and continue to stir to obtain the mixed solution B; and the molar ratio of Ni:Mo is 1:1;

[0040] Step four, 20mg sodium borohydride NaBH 4 Dissolve in 1mL of distilled water, add to the mixed solution B in step 3 as a reducing agent, stir at room temperature for 5-15min for reduction reaction, and obtain boron nitride supported Ni-MoO...

Embodiment 3

[0042] A Boron Nitride Supported Ni-MoO x The preparation method of nanometer catalyst comprises the following steps:

[0043] Step 1. Prepare 15 mg of an aqueous solution of hexagonal boron nitride BN with a concentration of 6 mg / mL, and obtain a uniformly dispersed hexagonal boron nitride BN aqueous solution after ultrasonic treatment for 15 to 120 minutes;

[0044] Step two, the NiCl of 0.5mmol 2 Add the aqueous solution to the BN aqueous solution in step 1, and continue to stir for 1 to 10 minutes to obtain the mixed solution A;

[0045] Step 3, then 0.5mmol of Na 2 MoO 4 Add the aqueous solution to the mixed solution A in step 2, and continue to stir to obtain the mixed solution B; and the molar ratio of Ni:Mo is 1:1;

[0046] Step four, 60mg sodium borohydride NaBH 4 Dissolve in 1mL of distilled water, add to the mixed solution B in step 3 as a reducing agent, stir at room temperature for 5-15min for reduction reaction, and obtain boron nitride supported Ni-MoO x n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com