Manufacturing method of mould with conformal cooling channel

A technology of conformal cooling and mold manufacturing, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of insufficient strength and low strength of parts, and achieve reduced internal stress, uniform and constant temperature, and mold cooling design and the effect of processing simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

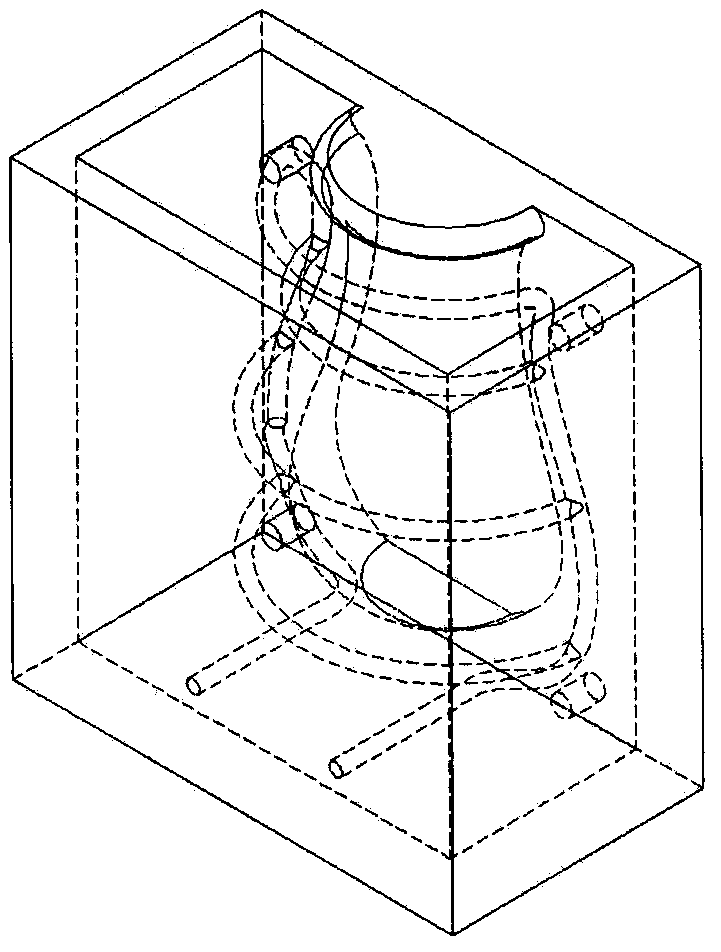

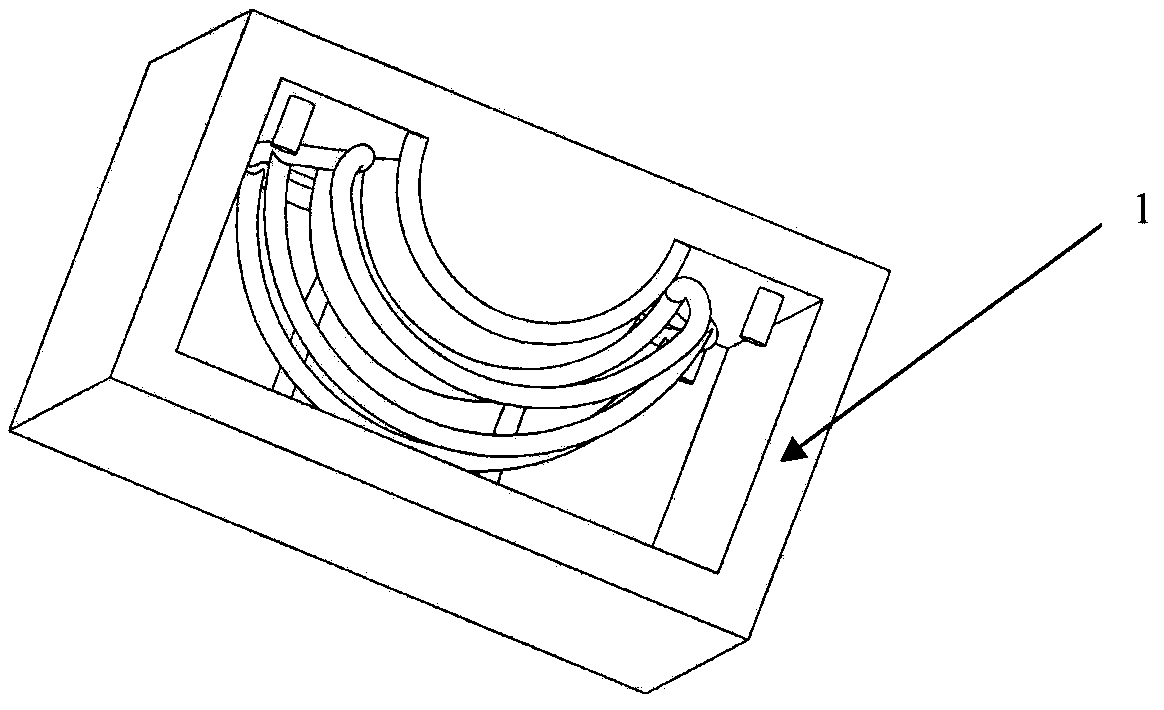

[0033] This embodiment is described by taking a blow mold as an example. figure 1 For the schematic diagram of the product to be processed by the mold, first design a mold diagram with a conformal cooling channel from the product diagram, obtain the 3D model data of the mold with a conformal cooling channel, and then convert the model data to hollow out the entity, holes, The pipes and hollows are transformed into entities, and the entity frame 1 is added, and the 3D model data of the sand mold used for casting and manufacturing mold blanks are obtained inversely. The 3D data of the sand mold has complex cores, which cannot be manufactured by conventional methods. However, it is easy to manufacture a sand mold that can be poured into a mold blank by 3D printing. Metal is poured into the sand mold to obtain a mold blank with a conformal cooling channel. The poured material can be the mold material to obtain a mold Castings are processed directly after roughing, and finally a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com