Thermal treatment device of field joint of steel containment of nuclear power plant and thermal treatment method

A steel containment and heat treatment device technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problem of inability to achieve uniform distribution and constant heat treatment temperature, inability to closely fit insulation cotton and heating block, and poor heat treatment quality No problems such as guarantee, to achieve the effect of improving the construction efficiency of heat treatment, strengthening the effect of heat conduction and heat preservation, and improving the quality of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

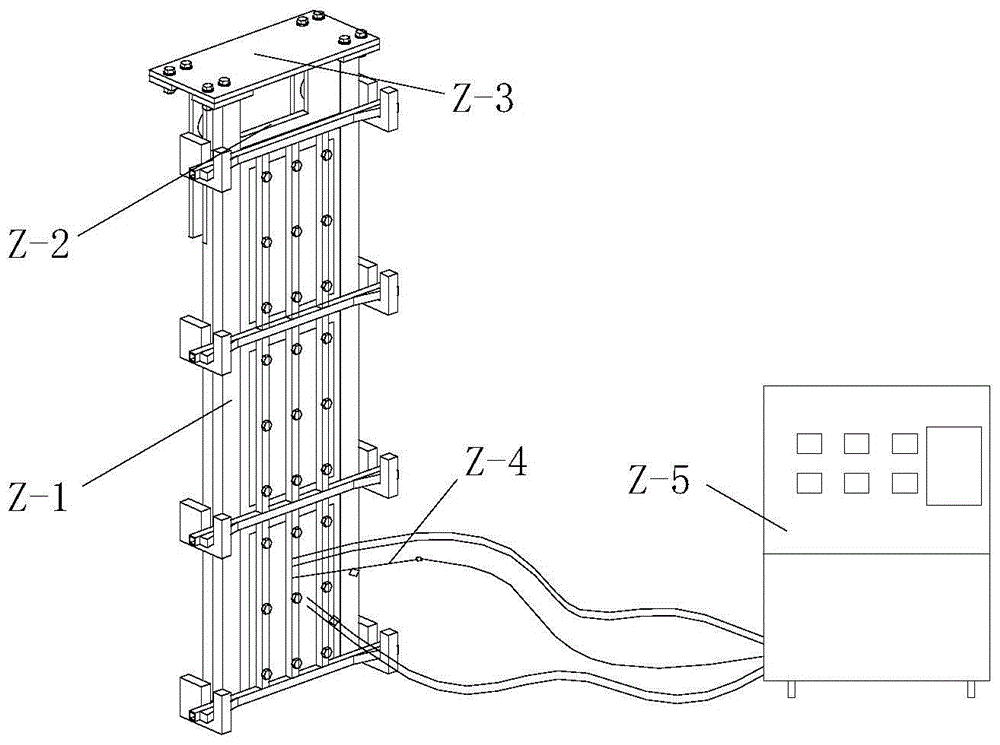

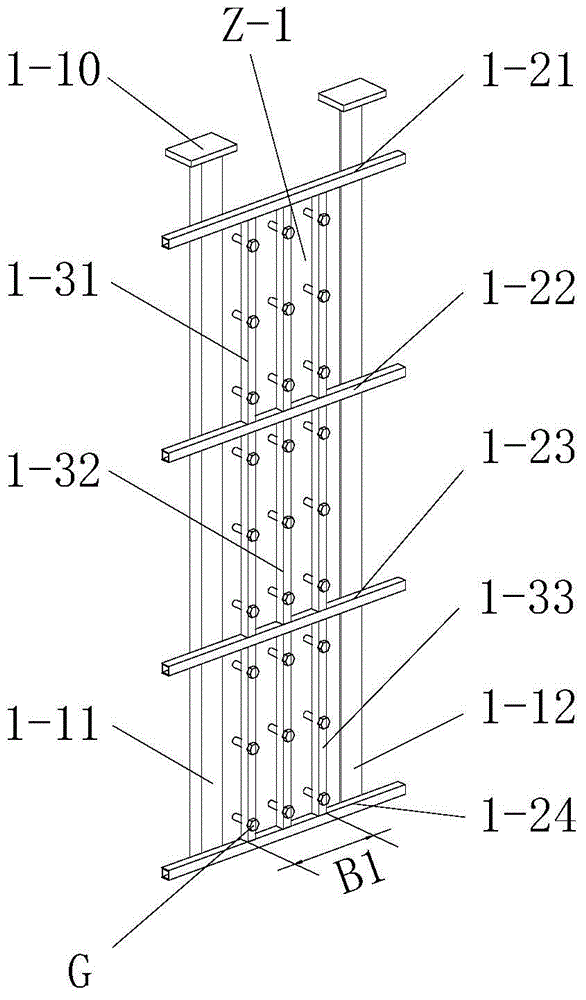

[0040] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

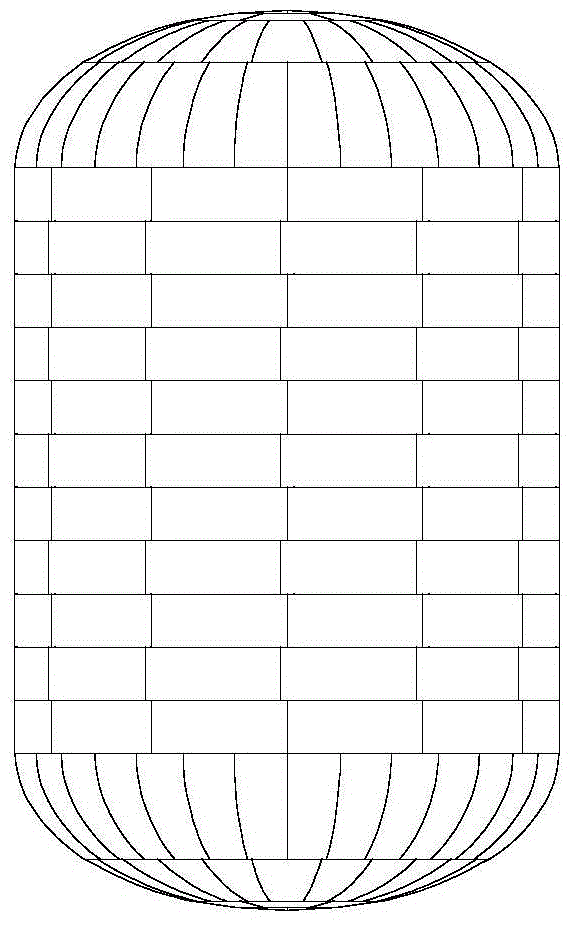

[0041] like figure 1 As shown, the nuclear power plant steel containment vessel (CV) in this embodiment includes three parts: a spherical bottom head, a cylindrical body and a spherical top head, with a diameter of 39.6m. Among them, the bottom head and the top head are tailor-welded from a total of 64 hyperboloid high-strength and tough SA738Gr.B steel plates. The cylinder body is composed of 11 rings of wall panels, each ring is made of 12 single-curved high-strength and tough SA738Gr.B steel plates, including 132 vertical welds (also known as longitudinal seams) and 12 circular seams. All welds need to be preheated before welding, and some welds need stress relief heat treatment after welding.

[0042] The pre-weld preheating treatment of the installation weld seam of the steel containment of the nuclear power plant in this embodiment adopts figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com