Preparing method for aluminum-based nano composite material

A nano-composite material and aluminum-based technology, applied in the field of metal-based composite materials, can solve the problems of weakening the reinforcing body on the strengthening effect, shape, size and distribution of the composite material, and achieve fine matrix grains and low reinforcement composition. Uniform and efficient manufacturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

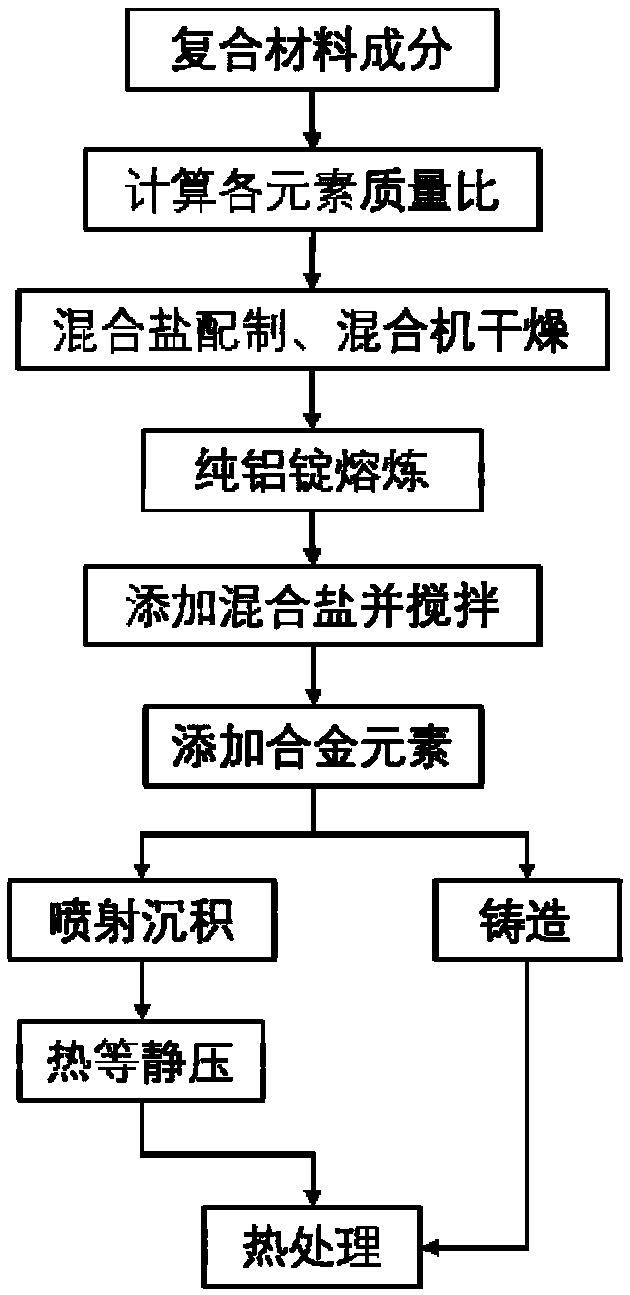

[0024] see figure 1 , the invention provides a method for preparing an aluminum-based nanocomposite, comprising the steps of:

[0025] (1) Calculate the mass ratio of each element according to the composition of the composite material.

[0026] (2) Prepare mixed salt according to the mass ratio, and place it in a mixer for drying. Specifically, the mixed salt is put into a powder mixer and mixed for 6-12 hours, then placed in a resistance furnace, and kept at 240-260° C. for 3-6 hours.

[0027] (3) Smelting pure aluminum ingots. Specifically, a medium-frequency induction furnace is used for melting, and the melting temperature is 750-800°C.

[0028] (4) Add the mixed salt into the pure aluminum melt and stir to form in-situ reinforced particles. Specifically, the process of adding the mixed salt to the pure aluminum melt takes 10-15 minutes. During the addition process, electromagnetic and mechanical stirring are applied, the stirring speed is 600-900 rpm, and the reaction...

Embodiment 1

[0035] This example provides an A356 / TiB 2 A method for preparing an aluminum-based nanocomposite material, comprising the following steps:

[0036] (1) Using the mixed salt reaction method to produce in-situ TiB 2 A356 composite material melt for reinforcement, the specific process is: according to A356 / 6%TiB 2 Nominal chemical composition of aluminum matrix composites Al-7Si-0.3Mg-6%TiB 2 , calculate the alloy element mass ratio of the aluminum matrix composite; according to the calculated mass ratio, firstly carry out KBF 4 and K2 TiF 6 Mix the mixed salt on the powder mixer for 8 hours, and then put the mixed salt in a resistance furnace at 250°C for 12 hours; the pure aluminum ingot is melted in an intermediate frequency induction furnace at a melting temperature of 800°C; after the pure aluminum is completely melted, Raise the melting temperature to 950°C, slowly add the mixed salt into the pure aluminum melt, and react to form TiB 2 Particles, electromagnetic and m...

Embodiment 2

[0041] This example provides A356 / Al 3 The preparation method of Zr aluminum-based nanocomposite material, comprises the following steps:

[0042] (1) Using the molten salt reaction method to produce in-situ Al 3 A356 composite material melt of Zr reinforcement, the specific process is: according to A356 / 3%Al 3 Nominal Chemical Composition of Zr Aluminum Matrix Nanocomposites Al-7Si-0.3Mg-3%Al 3 Zr, calculate the alloy element mass ratio of the aluminum-based nanocomposite; according to the calculated mass ratio, first carry out K 2 ZrF 6 Weigh it, and then place it in a resistance furnace at 250°C for 3 hours; the pure aluminum ingot is melted in an intermediate frequency induction furnace at a melting temperature of 800°C; after the pure aluminum is completely melted, the K 2 ZrF 6 Slowly add to the pure aluminum melt, the reaction generates Al 3 Zr particles, electromagnetic and mechanical stirring are applied during the addition process, the stirring speed is 600rpm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com