Aluminum-silicon/aluminum-silicon carbide gradient composite material and preparation method thereof

A technology of aluminum silicon carbide and composite materials, which is applied in the field of composite materials, can solve the problems of thermal expansion coefficient matching of electronic packaging materials, incompetence of lightweight and airtight welding, decreased life, and increased failure rate of electronic devices, etc. Ease of processing, performance-tunable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

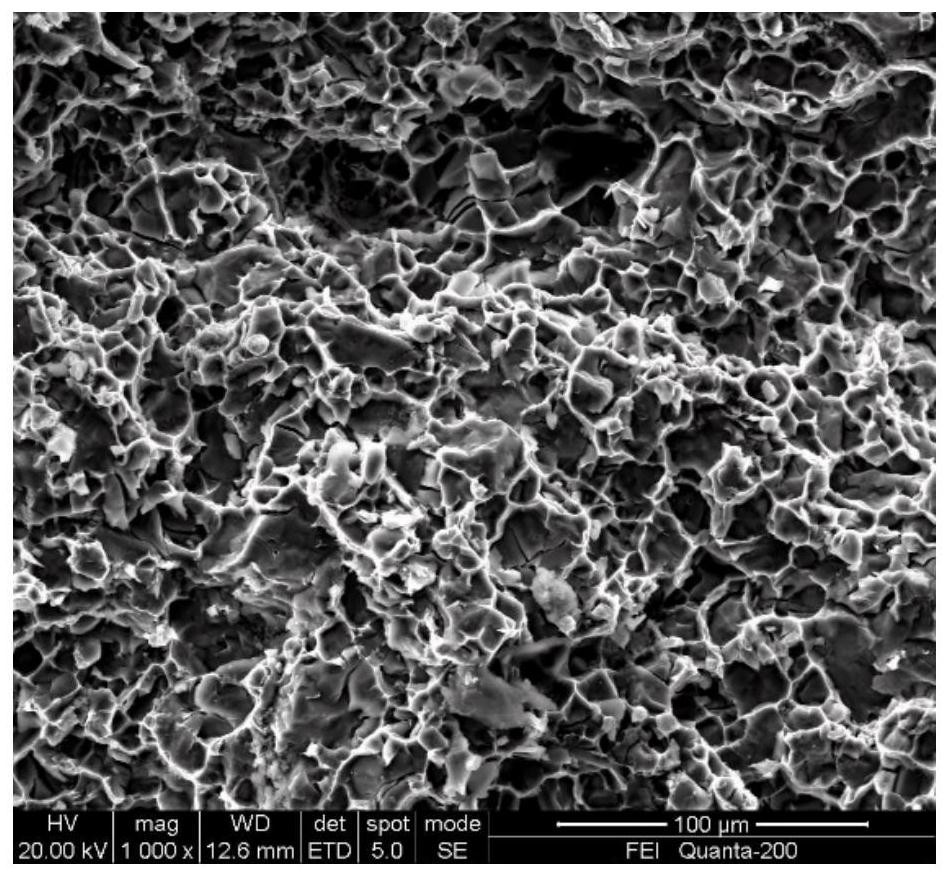

[0052] The aluminum-silicon / aluminum-silicon carbide gradient composite material designed in this embodiment is composed of two layers of aluminum-silicon alloy layer and one layer of aluminum-silicon carbide composite material layer; wherein, the weight percentage of aluminum in the two layers of aluminum-silicon alloy layer 27% and 50% respectively, the volume percentage of aluminum in the aluminum silicon carbide composite material layer is 60%; the aluminum alloy layer containing 50% aluminum is located in the aluminum alloy layer containing 27% aluminum and aluminum silicon carbide composite between material layers to obtain a three-layer gradient structure of Al27%Si-Al50%Si-Al60%SiC composite material.

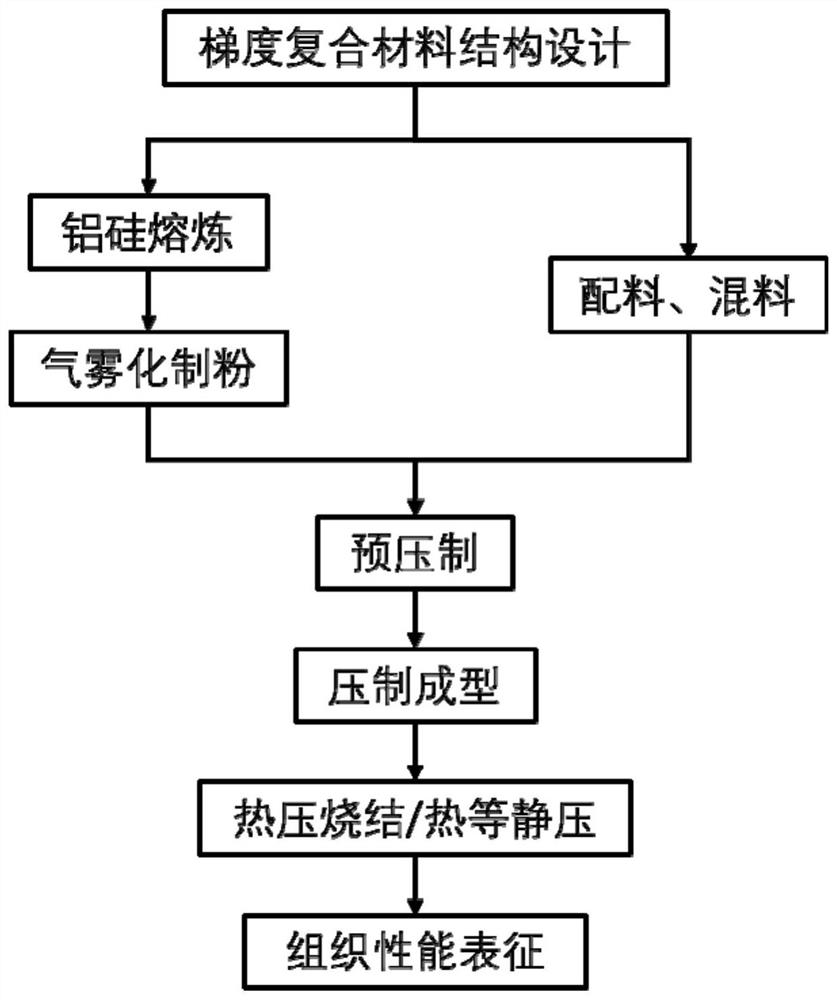

[0053] The specific steps for preparing the Al-Si / Al-SiC gradient composite material in this example are as follows:

[0054] (1) Select pure aluminum ingots and monocrystalline silicon ingots as raw materials, and mix the pure aluminum ingots and monocrystalline silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com