Integrated ultrasonic longitudinal-torsion composite turning tool suitable for difficult-to-machine material

An integrated and difficult-to-machine technology, applied in the direction of tools for lathes, metal processing equipment, tool holders, etc., it can solve the problems of unsatisfactory parts accuracy, difficult composite vibration of longitudinal buttons, complicated installation steps, etc. Compatibility, ease of installation and commissioning, effect of improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

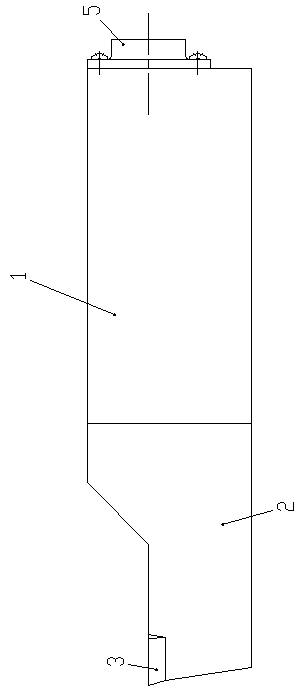

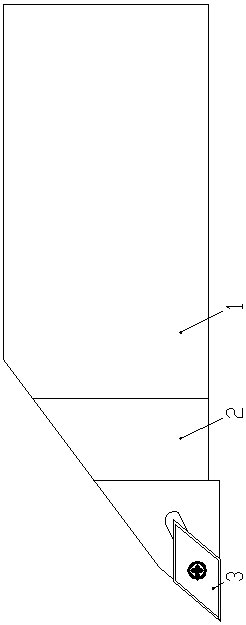

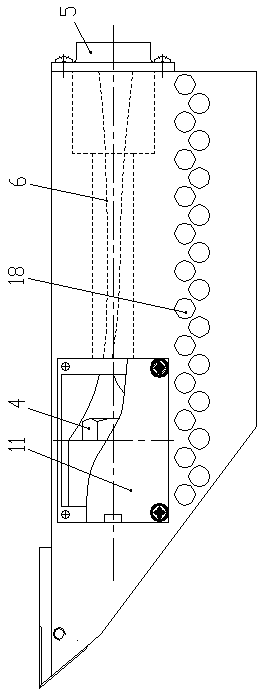

[0023] Such as Figure 1-7 As shown, the integrated ultrasonic longitudinal torsion composite turning tool suitable for difficult-to-machine materials of the present invention includes a cutter body 1, a cutter head 2 is connected to the front end of the cutter body 1, and the cutter head 2 is a wedge-shaped structure. 2 is equivalent to an ultrasonic horn, and the front end of the cutter head 2 is equipped with an organic clip blade 3, which is used for turning processing, a transducer assembly 4 is installed in the cutter body 1, and an aviation The plug 5, the aviation plug 5 is connected with the transducer assembly 4 through the input cable 6, the aviation plug 5 is externally connected to the ultrasonic power supply 7 through the cable, and after the ultrasonic power supply 7 applies the ultrasonic amplitude to the transducer assembly 4 through the aviation plug 5, it passes through the wedge-shaped knife The head 2 amplifies the amplitude to the required amplitude, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com