A kind of c9 thermal polymer resin and its preparation process with controllable molecular weight and softening point

A thermal polymer resin and preparation technology, which is applied in the field of petroleum resin preparation, can solve the problems of difficult petroleum resin molecular weight regulation and complicated operation, and achieve the effect of ensuring comprehensive performance, simple preparation process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

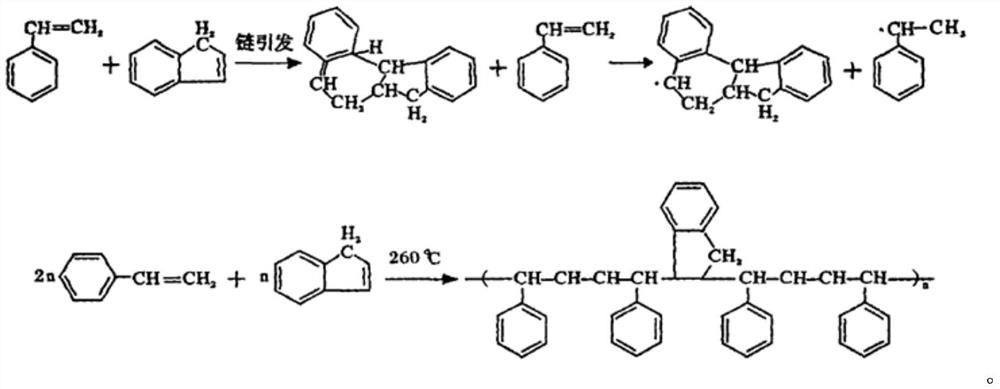

Method used

Image

Examples

Embodiment 1

[0032] Weigh 200g of deweighted C9 raw materials, 10g of dicyclopentadiene, 5g of methyldicyclopentadiene, 5g of styrene and styrene derivatives and dissolve them in 100g of solvent oil; then add the reaction materials to the thermal polymerization reactor Neutralize and stir evenly, under the protection of nitrogen atmosphere and under normal pressure, control the polymerization reaction temperature to 260°C, and the reaction time to 12h. After the reaction is completed, the polymerized reaction product is stripped to recover mineral spirits to obtain C9 thermal polymerized petroleum resin . The measured molecular weight Mz of the resin is 1100, and the softening point is 115°C. The deweighted C9 raw material in this example mainly contains the following components: 8% of styrene and its derivatives, 12% of methylstyrene and its derivatives, 16% of dicyclopentadiene, 13% of indene and its derivatives, 10% dicyclopentadiene, 25% of various alkanes below C9.

Embodiment 2

[0034] Weigh out 150g of C9 raw materials, 5g of dicyclopentadiene, 5g of methyldicyclopentadiene, 5g of styrene and styrene derivatives and dissolve them in 150g of solvent oil; then add the reaction materials to the thermal polymerization reactor Neutralize and stir evenly, under the protection of nitrogen atmosphere and under normal pressure, control the polymerization reaction temperature to 250℃, and control the reaction time to 15h. After the reaction is completed, the polymerized reaction product is stripped to recover mineral spirits to obtain C9 thermal polymerized petroleum resin . The measured molecular weight Mz of the resin is 1000, and the softening point is 103°C. The deweighted C9 raw material in this example mainly contains the following components: styrene and its derivatives 10%, methyl styrene and its derivatives 2%, dicyclopentadiene 14%, indene and its derivatives 12%, formaldehyde Dicyclopentadiene is 7%, and all kinds of alkanes below C9 are 30%.

Embodiment 3

[0036] Weigh 250g of deweighted C9 raw materials, 5g of dicyclopentadiene, 2g of methyldicyclopentadiene, 2g of styrene and styrene derivatives and dissolve them in 100g of solvent oil; then add the reaction materials to the thermal polymerization reactor Neutralize and stir uniformly, under nitrogen atmosphere protection and normal pressure, control the polymerization reaction temperature to 240℃, and the reaction time to 16h. After the reaction is over, the polymerized reaction product is stripped to recover mineral spirits to obtain C9 thermal polymerized petroleum resin . The measured molecular weight Mz of the resin is 1250, and the softening point is 126°C. In this embodiment, the deweighted C9 raw material mainly contains the following components: 9% of styrene and its derivatives, 15% of methylstyrene and its derivatives, 20% of dicyclopentadiene, 8% of indene and its derivatives, 10% dicyclopentadiene, 30% of various alkanes below C9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com