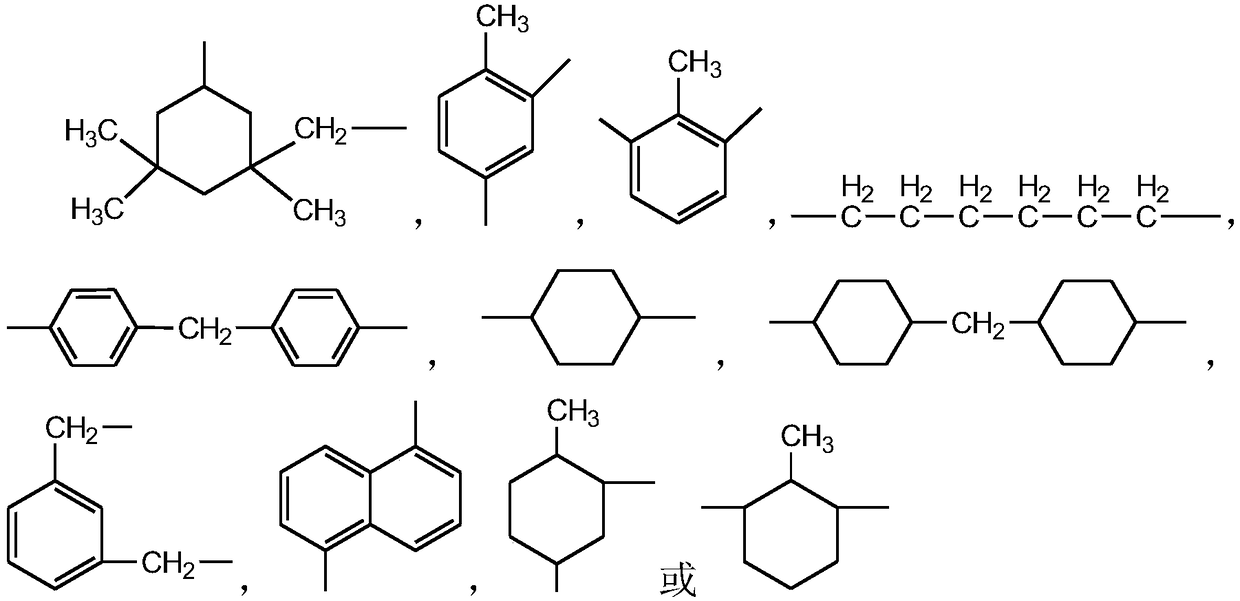

Polyurethane acrylate resin used for bonding PC plastic, and preparation method thereof

A polyurethane acrylate and acrylate technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as unsatisfactory adhesion and achieve high photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

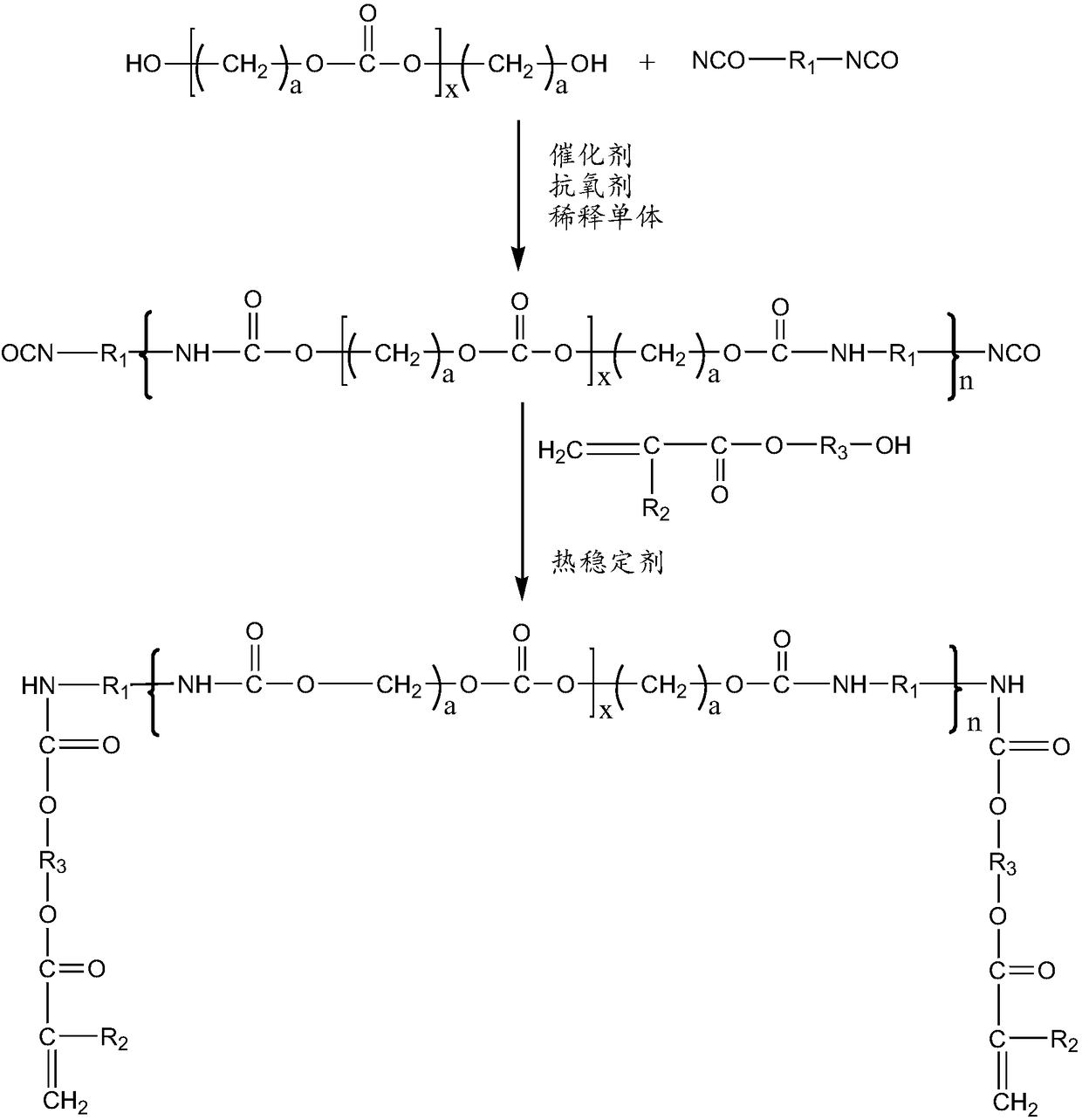

Method used

Image

Examples

Embodiment 1

[0037] Prepare polyurethane acrylate resin according to the following formula:

[0038] 10.0 parts of Sartomer's SR506, isopropyl acrylate

[0039] 22.95 parts of Bayer's IPDI, isophorone diisocyanate

[0040] 51.625 parts of AsahiKasei's T5651 polycarbonate diol

[0041] 0.194 parts of Irganox 1010 from BASF, antioxidant

[0042] 0.10 part of Rodia's HQ-MME, antioxidant

[0043] 11.745 parts of Kyoeisha's 2-HPA, 2-hydroxypropyl acrylate

[0044] 3.356 parts of Kyoeisha's 2-HEMA, 2-hydroxyethyl methacrylate

[0045] 0.030 parts of Goschmi DBTL organotin catalyst, dibutyltin dilaurate

[0046] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0047]The preparation process of the polyurethane acrylate resin of the present embodiment is as follows: (when the red component is added, there is no description in this step, please add)

[0048] 1. In protective gas N 2 In the environment, add a non-reactive monofunctional (meth)acrylate...

Embodiment 2

[0053] Prepare polyurethane acrylate resin according to the following formula:

[0054] 20.0 parts of Sartomer's SR506, isopropyl acrylate

[0055] 17.952 parts of Bayer's IPDI, isophorone diisocyanate

[0056] 53.849 parts of AsahiKasei's T5651 polycarbonate diol

[0057] 0.194 parts of Irganox 1010 from BASF, antioxidant

[0058] 0.10 part of Rodia's HQ-MME, antioxidant

[0059] 3.50 parts of Kyoeisha's 2-HPA, 2-hydroxypropyl acrylate

[0060] 4.375 parts of Kyoeisha's 2-HEMA, 2-hydroxyethyl methacrylate

[0061] 0.030 parts of Goschmi DBTL organotin catalyst, dibutyltin dilaurate

[0062] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0063] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com