Shading film and FPC (flexible circuit board)

A technology of light-shielding film and adhesive, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of high labor cost and difficulty in recruiting talents, and achieve the effect of reducing labor cost and good signal shielding effect. and anti-interference performance, the effect of shortening the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

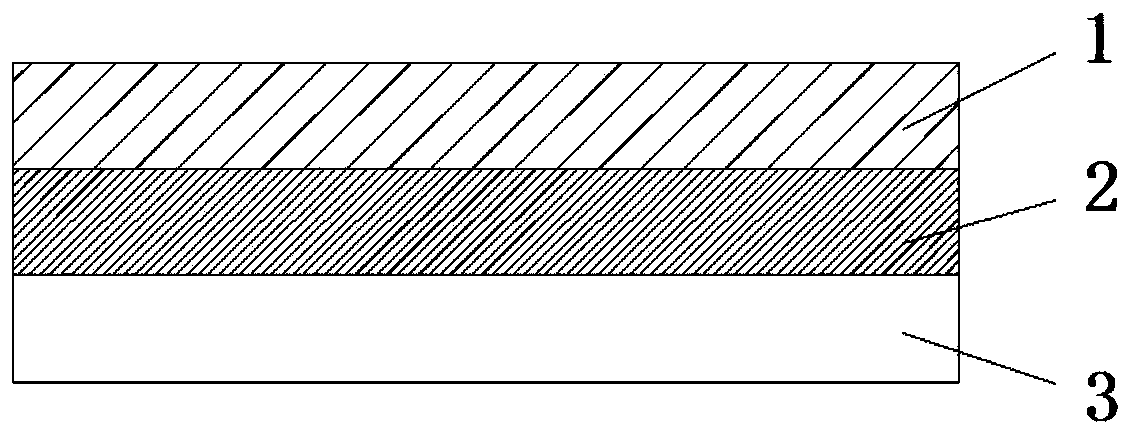

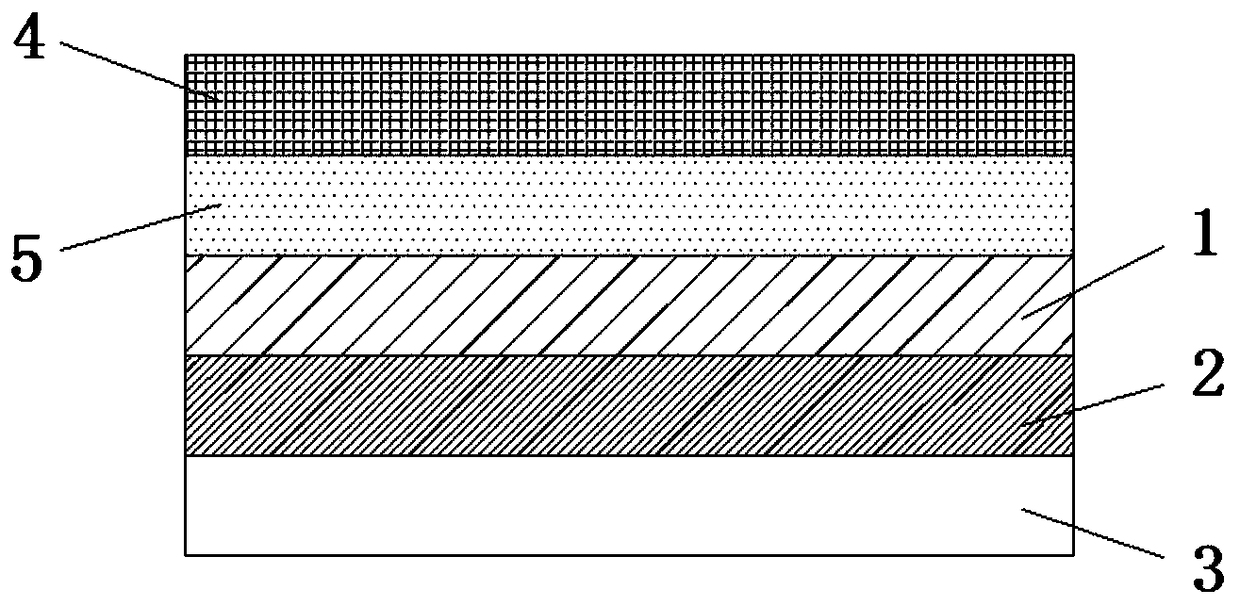

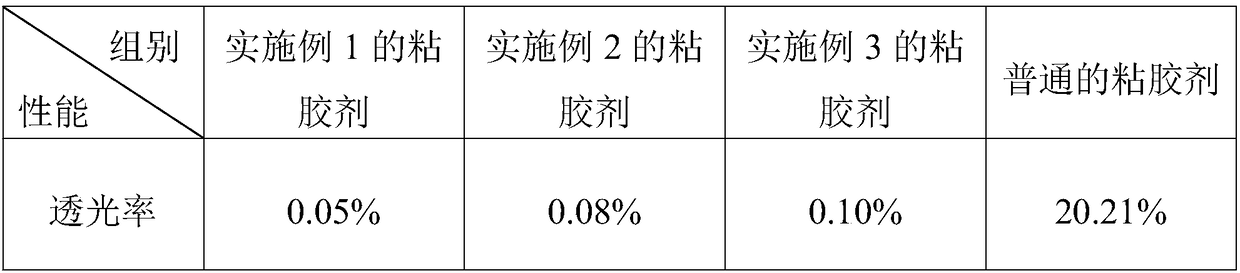

[0037] Such as figure 1 As shown, a light-shielding film includes a black PI layer 1, a black glue layer 2 and a copper foil 3, and the black PI layer 1, the black glue layer 2 and the copper foil 3 are sequentially coated and bonded by an adhesive, and the The adhesive comprises the following raw materials in percentage by weight: rubber 10%, flame retardant 10%, curing agent 3%, ion trapping agent 0.05%, antioxidant 0.1%, accelerator 0.1%, resin 15%, carbon powder 30% and Thinner 31.75%.

[0038] The black PI layer 1 is made of black matte PI. The copper foil 3 is electrolytic copper foil.

[0039] Adhesive raw material preparation instructions:

[0040] Rubber: 10% rubber, 90% thinner, 1072cgj for rubber, and MEK for thinner.

[0041] Flame retardant: 40% of rubber in this embodiment, 20% of flame retardant, 40% of diluent, OP935 is used for flame retardant, and MEK is used for diluent.

[0042] Curing agent: curing agent 20%, thinner: 80%, the curing agent is DDS, and...

Embodiment 2

[0053] Such as figure 1 As shown, a light-shielding film includes a black PI layer 1, a black glue layer 2 and a copper foil 3, and the black PI layer 1, the black glue layer 2 and the copper foil 3 are sequentially coated and bonded by an adhesive, and the The adhesive comprises the following raw materials in weight percentage: 15% rubber, 12% flame retardant, 5% curing agent, 0.1% ion trapping agent, 0.5% antioxidant, 0.5% accelerator, 20% resin, 40% carbon powder and Thinner 6.9%.

[0054] The black PI layer 1 is made of black matte PI. The copper foil 3 is electrolytic copper foil.

[0055] Adhesive raw material preparation instructions:

[0056] Rubber: 30% rubber, 70% thinner, 1072cgj for rubber, and MEK for thinner.

[0057] Flame retardant: 50% of rubber in this embodiment, 30% of flame retardant, 20% of diluent, OP935 is used for flame retardant, and MEK is used for diluent.

[0058] Curing agent: curing agent 40%, thinner: 60%, the curing agent is DDS, and the t...

Embodiment 3

[0069] Such as figure 1 As shown, a light-shielding film includes a black PI layer 1, a black glue layer 2 and a copper foil 3, and the black PI layer 1, the black glue layer 2 and the copper foil 3 are sequentially coated and bonded by an adhesive, and the The adhesive comprises the following raw materials in weight percentage: 12.5% of rubber, 11% of flame retardant, 4% of curing agent, 0.075% of ion trapping agent, 0.3% of antioxidant, 0.3% of accelerator, 17.5% of resin, 35% of carbon powder and Thinner 19.325%.

[0070] The black PI layer 1 is made of black matte PI. The copper foil 3 is electrolytic copper foil.

[0071] Adhesive raw material preparation instructions:

[0072] Rubber: 20% rubber, 80% thinner, 1072cgj for rubber, and MEK for thinner.

[0073] Flame retardant: 45% of rubber in this embodiment, 25% of flame retardant, 30% of diluent, OP935 is used for flame retardant, and MEK is used for diluent.

[0074] Curing agent: curing agent 30%, thinner: 70%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com