Inorganic lead halide perovskite quantum dot, preparation method of quantum dot, nanowire and preparation method of nanowire

A technology of lead halide and perovskite, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of low repeatability, low reaction yield, small output, etc., and achieve mass production and preparation Simple process and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In a first aspect, the present invention provides a method for preparing inorganic lead halide perovskite quantum dots, comprising:

[0031] Add cesium carbonate, lead halide, oleic acid, oleylamine, and octadecene into the container to form a precursor solution, the molar ratio of the cesium carbonate to the lead halide is 1:2-4, the oleic acid, oleylamine, The volume ratio of octadecene is 1:1:18-22. When 1 mmol of the cesium carbonate is added, 0.5 ml of the oleic acid is added correspondingly; the precursor solution is ultrasonicated; the precursor solution is centrifuged, The supernatant liquid obtained by centrifugation is the dispersion liquid of inorganic lead halide perovskite quantum dots.

[0032] Optionally, the molar ratio of the cesium carbonate to the lead halide is 1:3, and the volume ratio of the oleic acid, oleylamine, and octadecene is 1:1:20.

[0033] Optionally, the ultrasonic power is 150W, and the ultrasonic time is 10min.

[0034] Optionally, t...

Embodiment 1

[0044] This embodiment provides a preparation method of inorganic lead halide perovskite quantum dots:

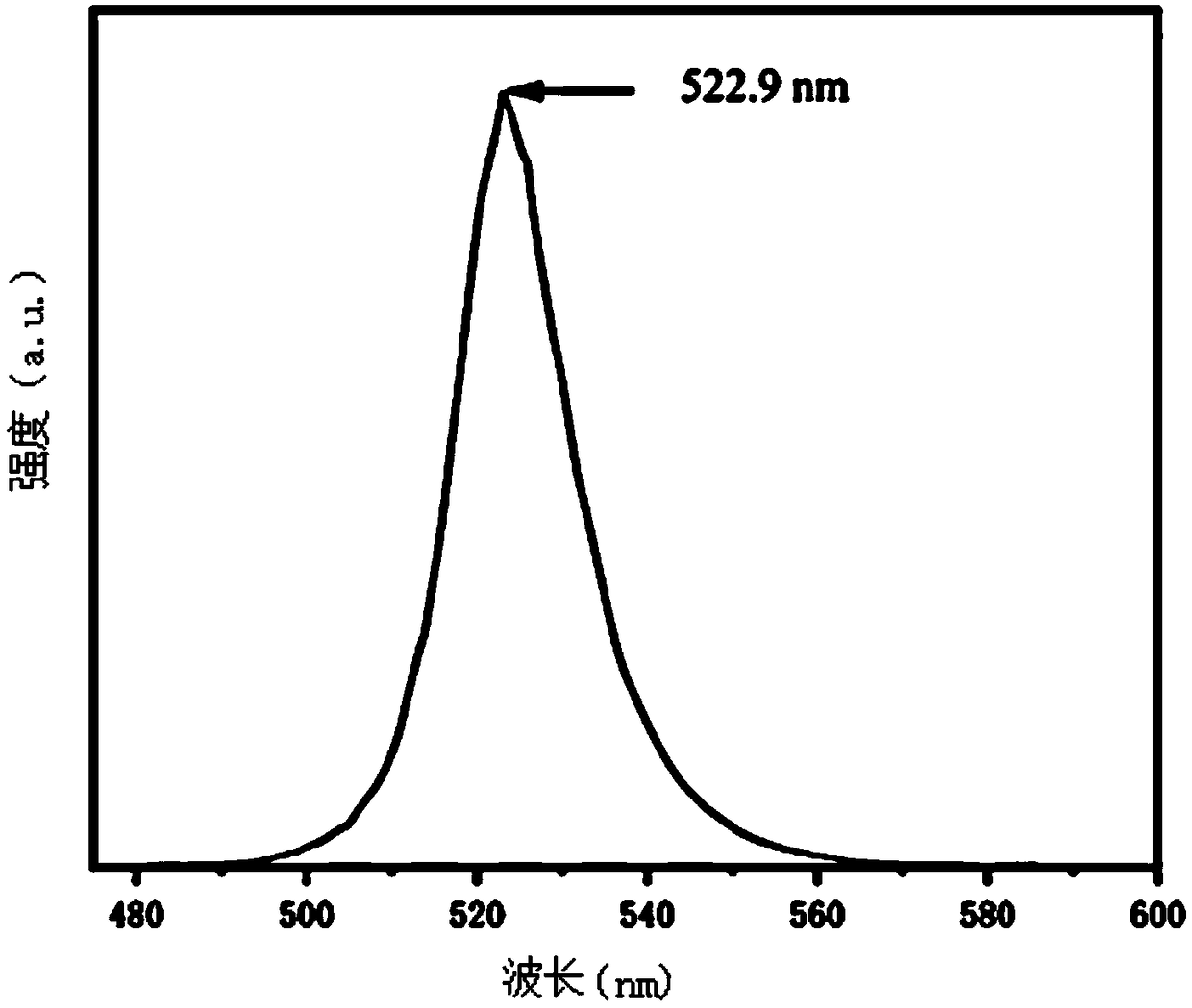

[0045] First 0.032g Cs 2 CO 3 , 0.1101g PbBr 2 , 0.5mL oleic acid, 0.5mL oleylamine, and 10mL octadecene solution were sequentially added into a 40mL beaker to form a precursor solution. Place the beaker containing the precursor solution in the working area of the ultrasonic machine (FS-300N ultrasonic machine of Shanghai Acoustic Instrument Co., Ltd.), adjust the position of the probe of the ultrasonic machine so that it is located at 3 / 4 of the liquid level of the precursor solution, and set The ultrasonic power is 150W, and the ultrasonic time is 10min. The color of the solution in the beaker gradually changed from colorless and transparent to light green, until finally it turned into bright yellow, indicating that the inorganic lead halide perovskite CsPbBr 3 Quantum dots have been prepared.

[0046] After the ultrasound is finished, take 10 mL of the reacted liq...

Embodiment 2

[0049] This embodiment provides an inorganic lead halide perovskite quantum dot, that is, CsPbBr 3 Quantum dot, the CsPbBr that will be prepared by embodiment 1 3 The quantum dot dispersion is subjected to suction filtration, and the filter cake obtained by suction filtration is dried to obtain CsPbBr 3 quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com