Foreign body manual removal method of laser foreign body removal device

A technology for removing foreign objects and lasers, applied in overhead lines/cable equipment, etc., can solve the problems of complex control, complex environment, labor and material resources, etc., and achieve the effect of improving operation accuracy, high control accuracy and high cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

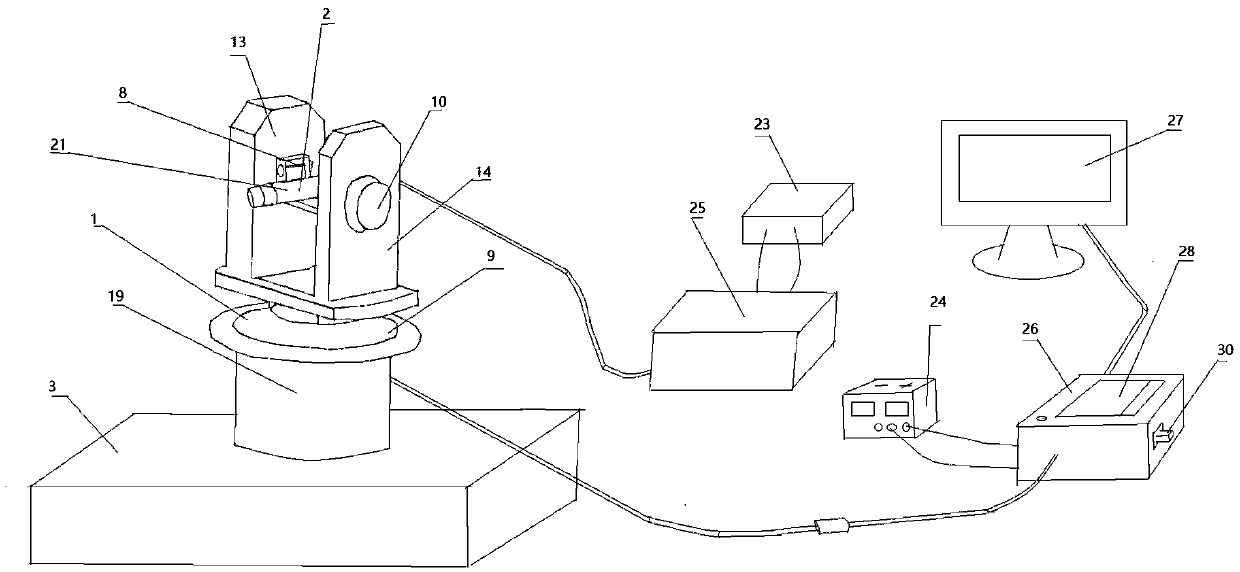

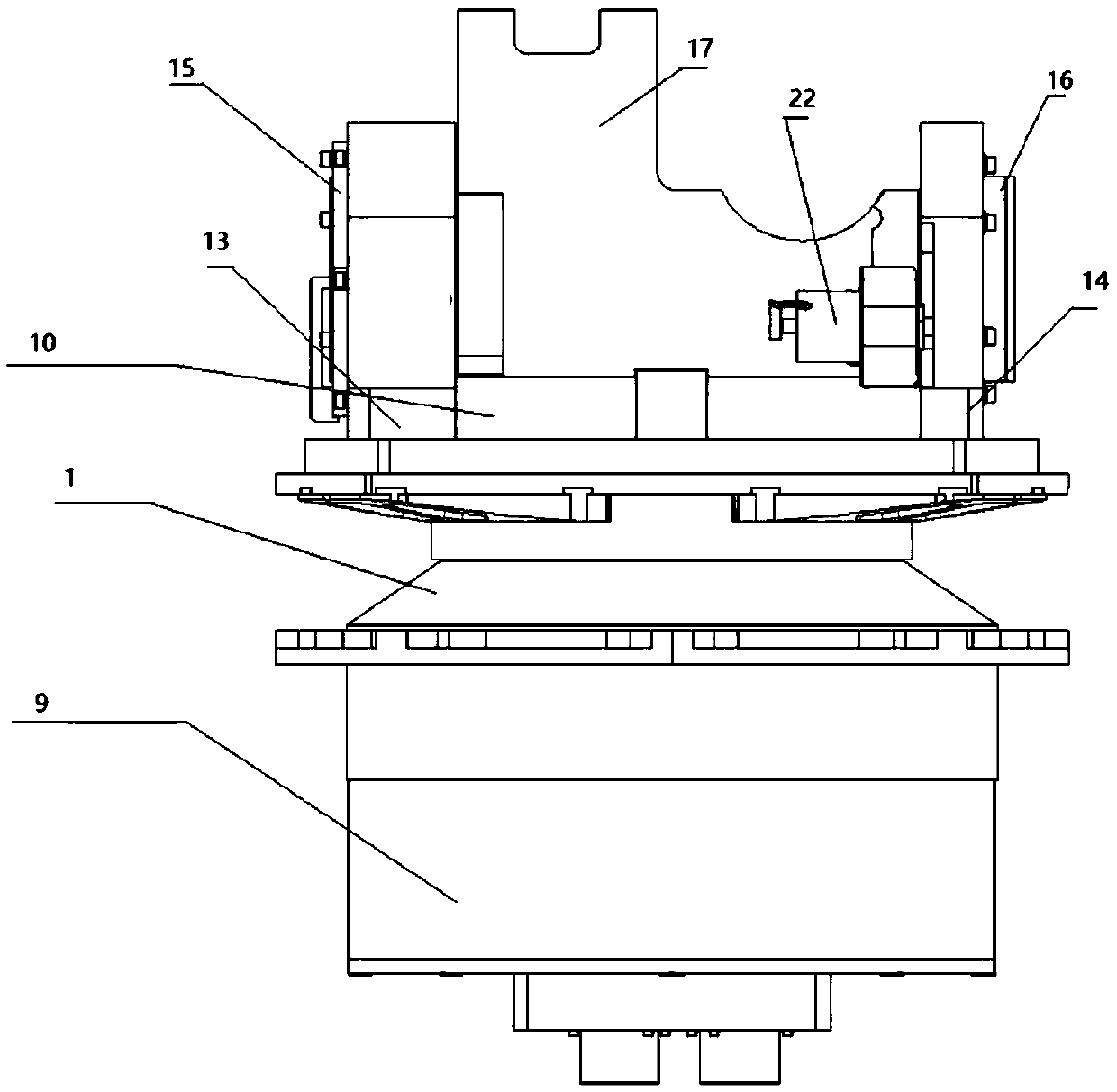

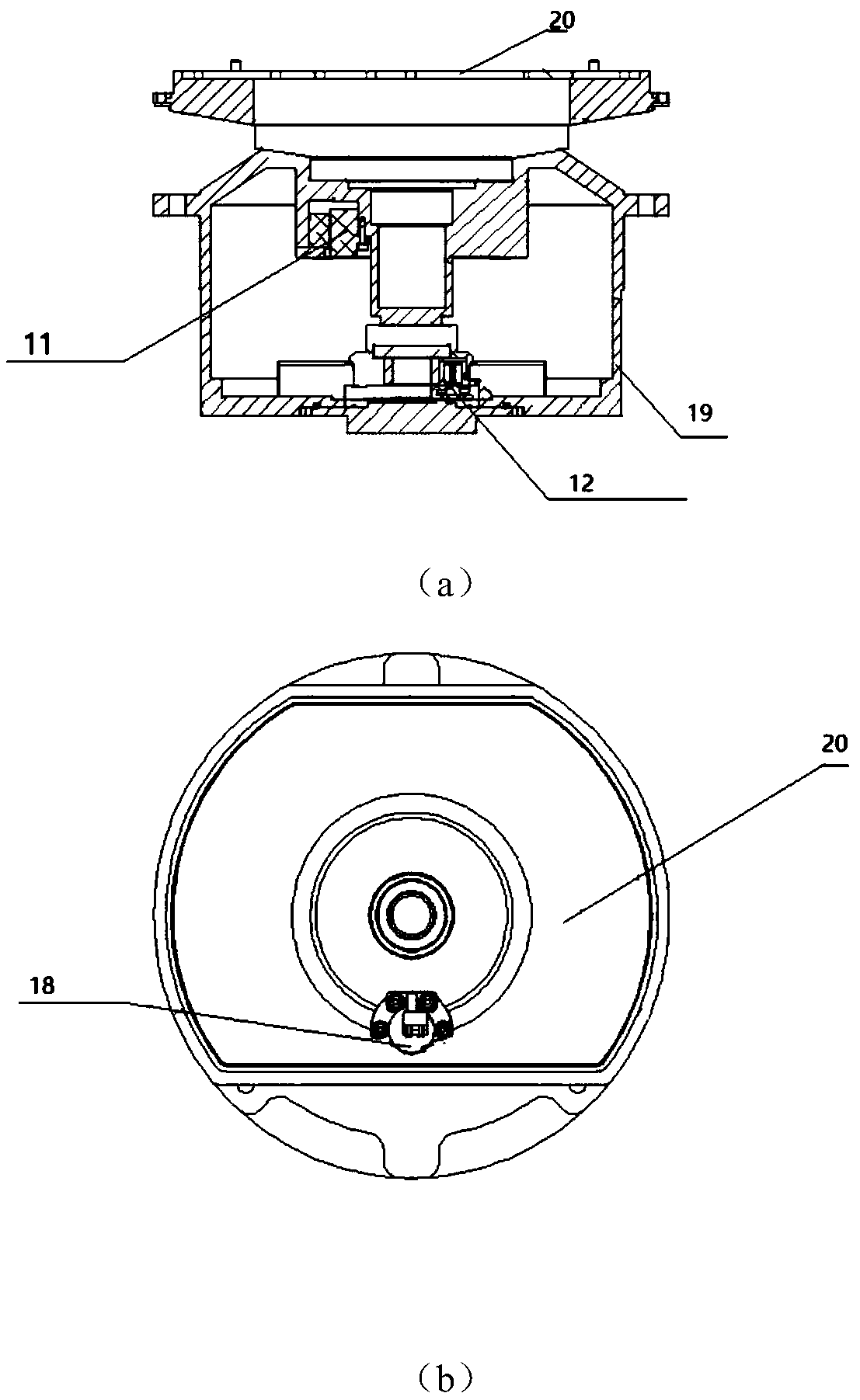

[0027] Such as figure 1 Shown is a schematic diagram of the assembly structure of the laser foreign body removal device using the method of the present invention. The device includes a turntable 1, a laser component 2, a base 3, a power supply system, an input and output device, a control system, a communication module, and a vision sensor 8 (preferably HD Industrial camera), where the turntable 1 includes an orientation component 9 and a tilt component 10. The azimuth component 9 is installed above the base 3, including the azimuth torque motor 11, the azimuth angle measuring device (resolver transmitter or electronic encoder) 12; the pitch component 10 is installed above the azimuth component 9, including bearing seat 13 and bearing seat 2. 14. Pitching torque motor 15; laser component 2 includes laser emitting head 21 and laser control box 25, lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com