Tea processing device

A processing device and tea technology, which is applied in tea treatment before extraction, drying gas arrangement, lighting and heating equipment, etc., can solve problems such as unfavorable tea effective cleaning, loss of tea nutrients, damage to tea integrity, etc., to achieve simple structure, The effect of maintaining integrity and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

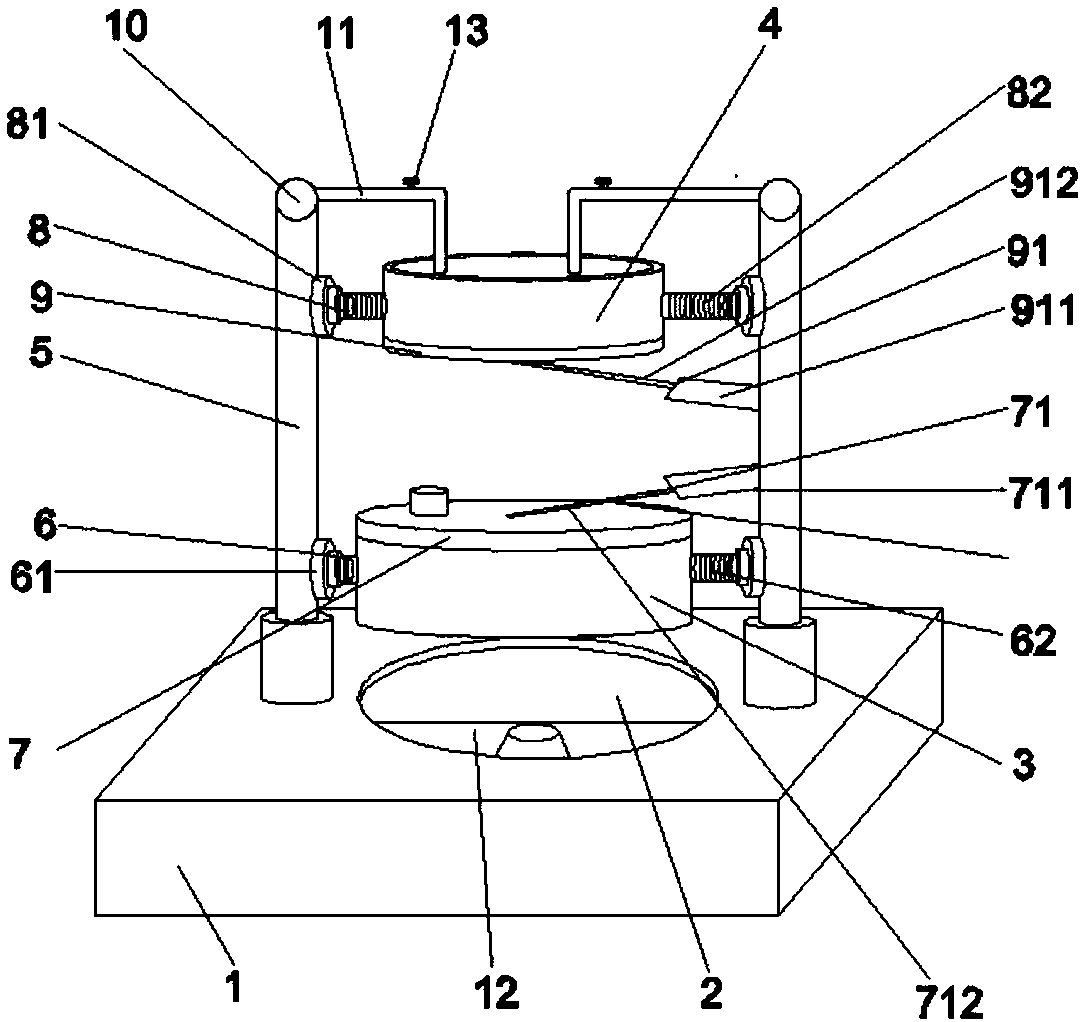

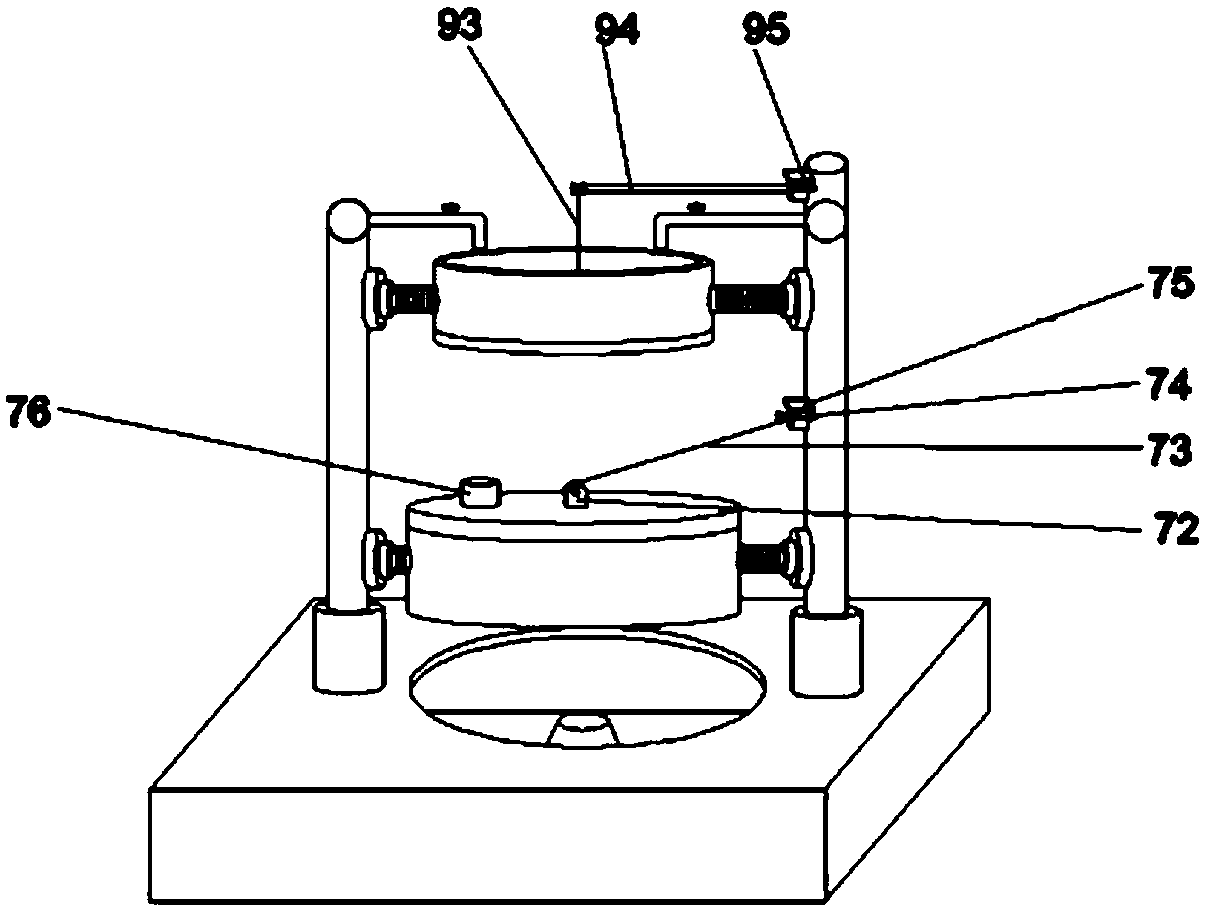

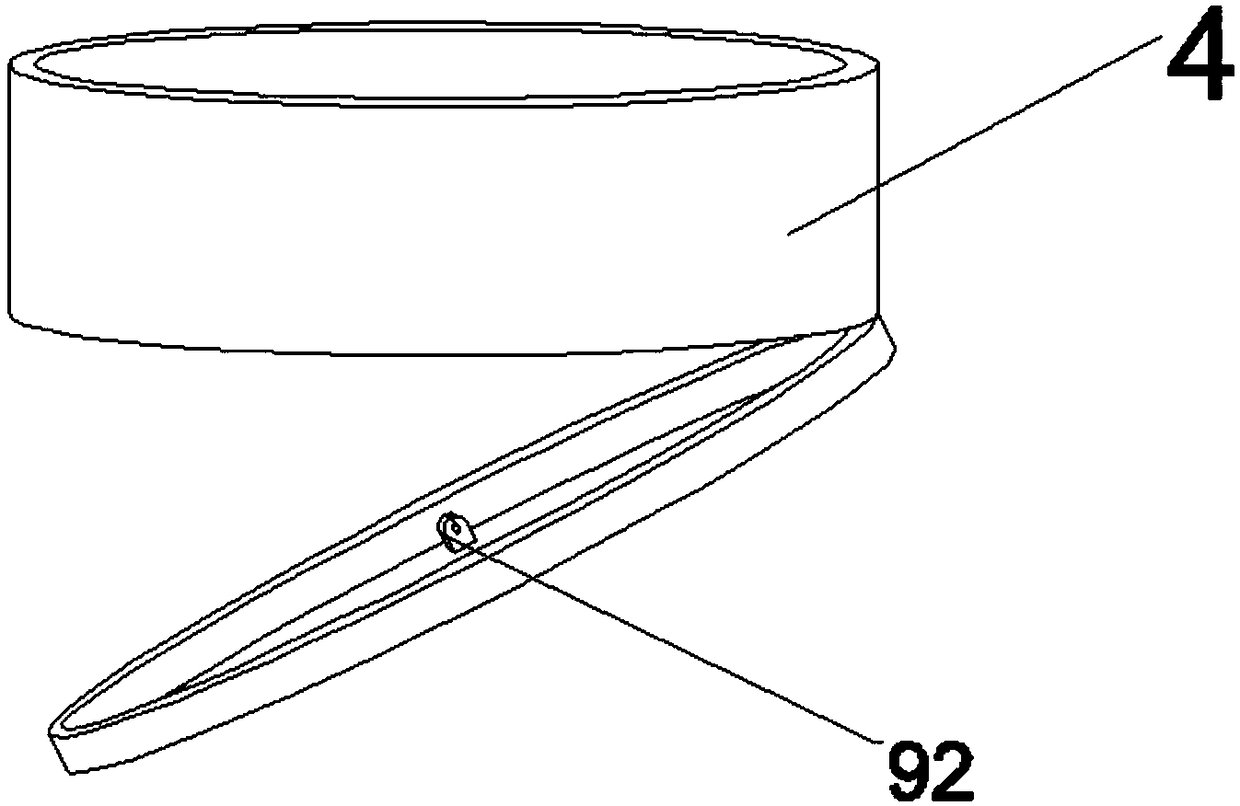

[0030] A tea processing device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes a water tank 1, the upper part of the water tank 1 is provided with an opening 2, and the top of the water tank 1 is vertically provided with two hollow pipes 5, and a drying device 3 and a cleaning device are arranged between the two pipes 5 4. The bottom of each of the pipelines 5 communicates with the water tank 1, and the top of each of the pipelines 5 is provided with a water pump 10, and the upper end of the pipeline 5 is sequentially connected to the suction pipe 10 and the drain pipe 11, and the drain pipe 11 Placed above the cleaning device 4, the drying device 3 is fixed between the two pipelines 5 by the first vibrating device 6, and a top cover 7 is hinged on the top of the drying device 3, and the top cover 7 A top cover opening device 71 is provided on the top, a screen 31 is provided at the bottom of the drying device 3, and the bottom of the...

Embodiment 2

[0033] Based on Example 1, such as figure 1 , figure 2 As shown, the first vibrating device 6 includes a first vibrating shaft 62 connected to the drying device 3 and a first vibrating motor 61 connected to the first vibrating shaft 62, and the first vibrating motor 61 is placed in the On the pipeline 5; the second vibrating device 8 includes a second vibrating shaft 82 connected with the cleaning device 41 and a second vibrating motor 81 connected with the second vibrating shaft 82, and the second vibrating motor 81 is placed in the Pipeline 5 on.

Embodiment 3

[0035] Based on Example 1, such as figure 1 , figure 2 As shown, the water tank 1 is provided with a membrane bioreactor 12 for purifying sewage. The membrane bioreactor 12 installed in the water tank 1 can purify and treat sewage, and the purified sewage can be absorbed and utilized again to achieve the purpose of saving water resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com