A car deformation recovery device

A deformation recovery, automobile technology, applied in special positions of vehicles, vehicle parts, vehicle seats, etc., can solve problems such as life-threatening, and achieve the effect of reducing injuries and eliminating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: As the vehicle deforms after a crash occurs, it may even trap people in the driver's seat or the passenger's seat, and rescue is difficult, which can easily cause life threats. However, the shape memory alloy is used in the steel beam of the car's driver's seat or the co-pilot, and the shape memory alloy is hollow inside and equipped with a heating device. Then, after a crash, the heating device heats up to its deformation temperature. The shape memory alloy can be restored to its original shape, which can better rescue the trapped. Shape memory alloys can be selected from Ni-Ti alloys, Cu-Al alloys, Cu-Zn-Al alloys, Cu-Zn-Sn alloys, Cu-Zn-Si alloys, Cu-Sn alloys with a deformation temperature in the range of 80-200℃ , Cu-Zn-Ga alloy, In-Ti alloy, Au-Cu-Zn alloy, NiAl alloy, Fe-Pt alloy, Ti-Ni alloy, Ti-Ni-Pd alloy, Ti-Nb alloy, U-Nb alloy and Fe-Mn-Si alloy, etc. In order to save costs, it can also be arranged only at the corners or spaced apart at the c...

Embodiment 2

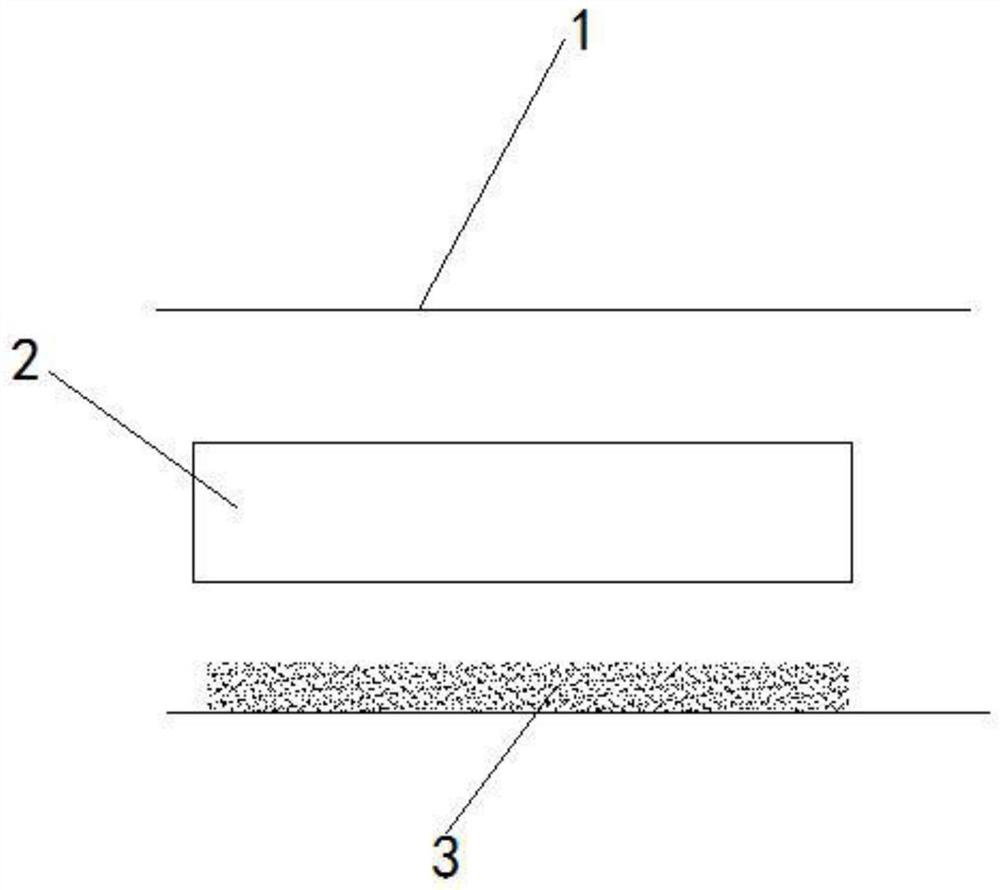

[0022] Embodiment two: such as figure 1 As shown, on the basis of Example 1, the heating device includes quicklime 3 and an aqueous solution (the mass ratio of quicklime to aqueous solution is 1:3-5), if the pH of the aqueous solution <7, it will release more heat when reacting with quicklime 3, which can be selected according to needs. The aqueous solution is set in the sealed container 2. When a crash occurs, the sealed container 2 is broken due to the deformation and extrusion of the vehicle (the sealed container is made of brittle materials such as glass and ceramics), and the aqueous or acid solution flows out and mixes with quicklime 3. The heat generated by the reaction heats the shape memory alloy 1 to restore the shape of the shape memory alloy 1 to the shape before the collision, and prevents the driver or passenger seat from being trapped.

Embodiment 3

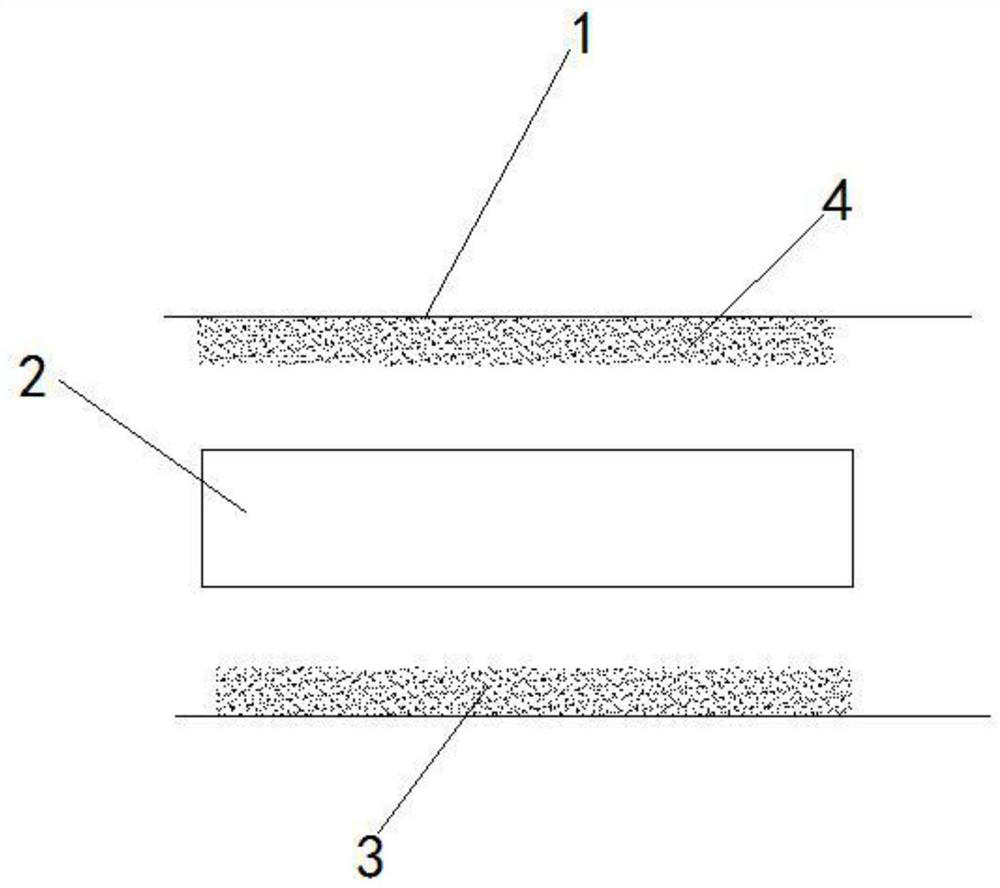

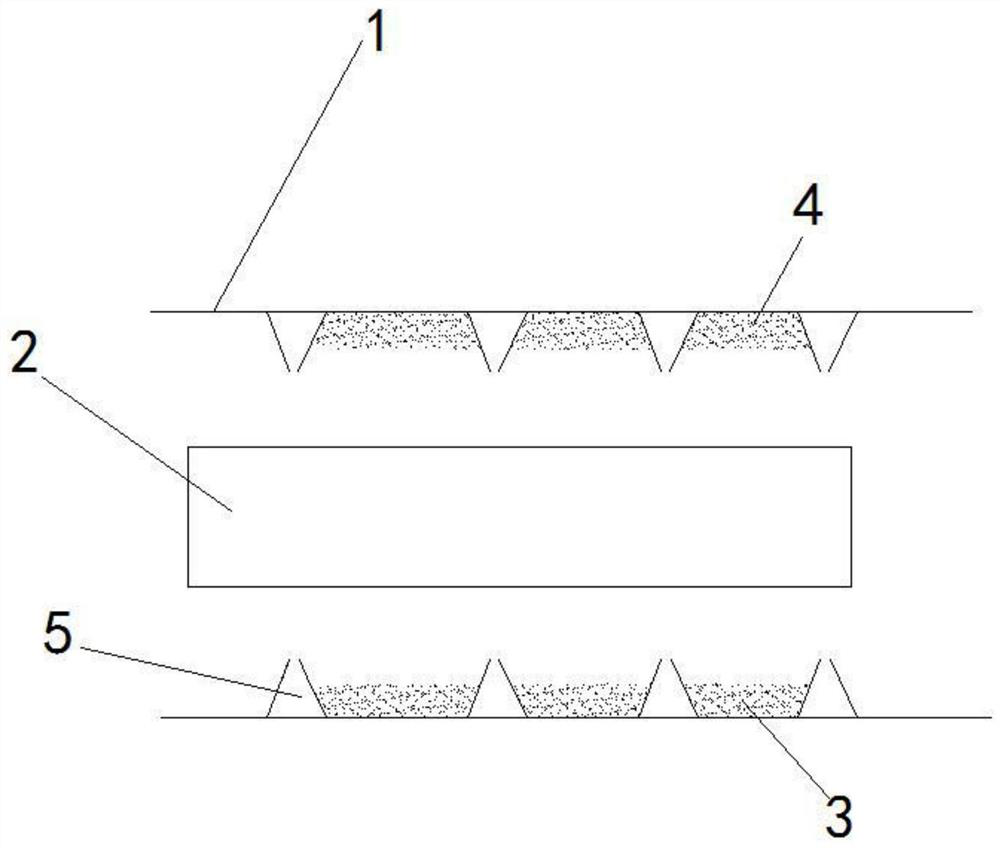

[0023] Embodiment three: such as figure 2 Said, on the basis of the second embodiment, the heating device also includes a solid acid (the solid acid can be trichloroacetic acid, periodic acid, dinitrobenzoic acid, ethylenediaminetetraacetic acid, p-toluenesulfonic acid, p-toluenesulfonic acid, Hydroxybenzenesulfonic acid, phosphorous acid, heteropoly acid and solid super acid, etc.; it can also be natural clay (such as bentonite, montmorillonite, kaolin, etc.), embodied acid (such as embodied in SiO 2 , Phosphoric acid, sulfuric acid, boric acid, etc. on diatomaceous earth), oxides (such as alumina, zirconia, titanium oxide, etc.), mixed oxides (such as SiO2-Al2O3, ZrO2-SiO2), zeolite, resin (cation exchange resin) Such as polystyrene sulfonic acid type resin), activated carbon, etc.) 4, the solid acid 4 can be separately arranged inside the shape memory alloy 1 (not in contact with quicklime) or adsorbed inside the porous material, when the aqueous solution (PH <≤7) When flowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com