Production process of 2-methyl-4-chlorophenoxyacetic acid

A technology of chlorophenoxyacetic acid and production process, which is applied in the field of pesticides, can solve the problems of high waste water and waste gas discharge, less than 10,000 tons, and slow chlorination efficiency, so as to improve chlorination efficiency, good social benefits, and reduce chlorine gas consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

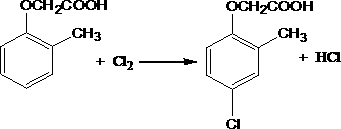

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will not be described below in conjunction with the embodiments.

[0020] The first step: Sodium chloroacetate preparation: Weigh quantitative chloroacetic acid into the sodium phosphate reaction kettle, add measured water or waste phenol water according to the proportion of liquid alkali content, start stirring, turn on the refrigerator to cool down the sodium phosphate reaction kettle, After the chloroacetic acid is completely dissolved, start to slowly add liquid caustic soda into the kettle, and strictly control the reaction temperature to ≤25°C. At the end of the reaction, the pH of the material should be controlled to be 7-8. After stirring for 20 minutes, check the pH value, and stop stirring after passing the test. When receiving the material loading notice, the pH value needs to be tested again to ensure that the qualified material liquid enters the next process.

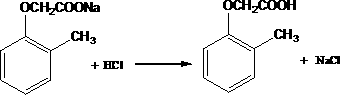

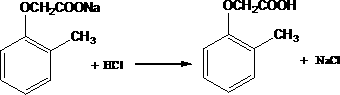

[0021] ①The synthesis of sodium chloroacetate: (sodium acid)

[0022] ClC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com