Lining layer material for deep sea oil pipeline and preparation method thereof

An oil transportation and lining technology, which is applied in the field of deep-sea oil transportation pipeline lining material and its preparation, can solve the problems of short life, poor high temperature resistance and corrosion resistance, and achieves low cost, good heat resistance, The effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

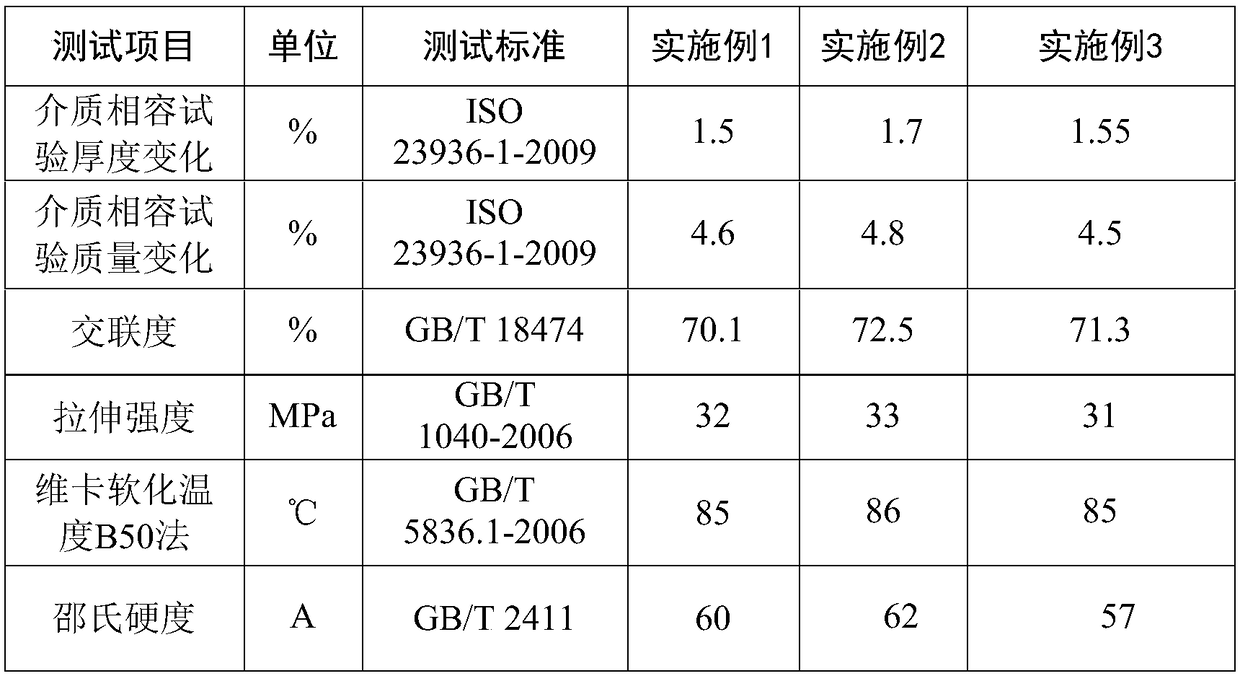

Examples

Embodiment 1

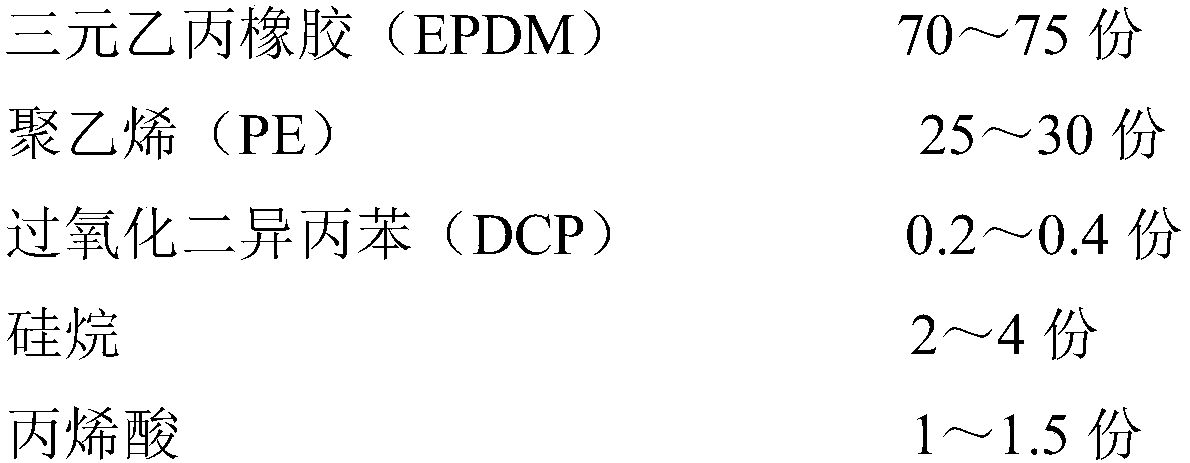

[0031] The water delivery hose of the present embodiment is made of the following parts by weight of material A and material B:

[0032] The mass percentage of A material is 85%, and the percentage of B material is 15%.

[0033] Calculated in parts by weight, material A contains the following parts by weight: EPDM 70 parts, polyethylene (PE) 30 parts, dicumyl peroxide (DCP) 0.2 parts, silane 2 parts, acrylic acid 1 copy;

[0034] Calculated in parts by weight, material B contains the following ingredients in parts by weight: 100 parts of polyethylene (PE), 2 parts of antioxidant, and 1 part of catalyst dibutyltin dilaurate.

[0035] The preparation method of the present embodiment is as follows:

[0036] (1) Drying of raw materials: EPDM and PE are dried at 60°C for 3 hours to keep the moisture content below 0.8%.

[0037] (2) Production of material A (silane grafting material): Mix the corresponding parts of ethylene propylene diene monomer (EPDM), polyethylene (PE), dicum...

Embodiment 2

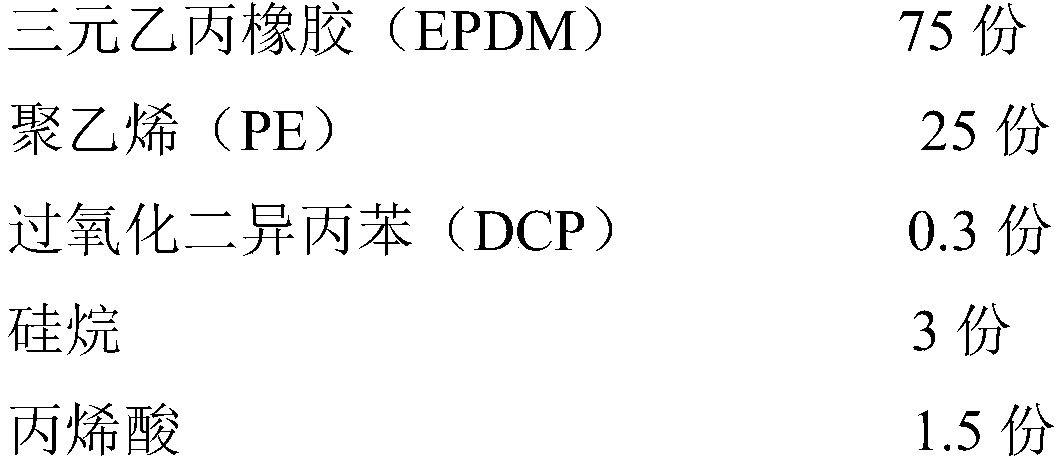

[0041] The water delivery hose of the present embodiment is made of the following parts by weight of material A and material B:

[0042] The mass percentage of A material is 85%, and the percentage of B material is 15%.

[0043] Calculated in parts by weight, material A contains the following parts by weight: EPDM 75 parts, polyethylene (PE) 25 parts, dicumyl peroxide (DCP) 0.3 parts, silane 3 parts, acrylic acid 1.5 copies;

[0044] Calculated in parts by weight, material B contains the following components by weight: 100 parts of polyethylene (PE), 2 parts of antioxidant, and 1.3 parts of catalyst dibutyltin dilaurate.

[0045] The preparation method of the present embodiment is as follows:

[0046] (1) Drying of raw materials: Dry EPDM and polyethylene (PE) at 70°C for 2.8 hours to keep the moisture content below 0.8%.

[0047] (2) Production of material A (silane grafting material): Mix the corresponding parts of ethylene propylene diene monomer (EPDM), polyethylene (PE...

Embodiment 3

[0051] The water delivery hose of the present embodiment is made of the following parts by weight of material A and material B:

[0052] The mass percentage of A material is 85%, and the percentage of B material is 15%.

[0053] The mass percentage of A material is 85%, and the percentage of B material is 15%.

[0054] Calculated in parts by weight, material A contains the following parts by weight: EPDM 75 parts, polyethylene (PE) 25 parts, dicumyl peroxide (DCP) 0.4 parts, silane 4 parts, acrylic acid 1.5 copies;

[0055] Calculated in parts by weight, material B contains the following components by weight: 100 parts of polyethylene (PE), 3 parts of antioxidant, and 1.6 parts of catalyst dibutyltin dilaurate.

[0056] The preparation method of the present embodiment is as follows:

[0057](1) Drying of raw materials: Dry EPDM and polyethylene (PE) at 80°C for 2.6 hours to keep the moisture content below 0.8%.

[0058] (2) Production of material A (silane grafting materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com