Composite filling particle for preparing high-strength non-woven fabric and preparation method and application thereof

A non-woven fabric and high-strength technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of easy tearing, low tensile strength, and poor recyclability, and achieve excellent performance, high tensile performance, good surfactant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

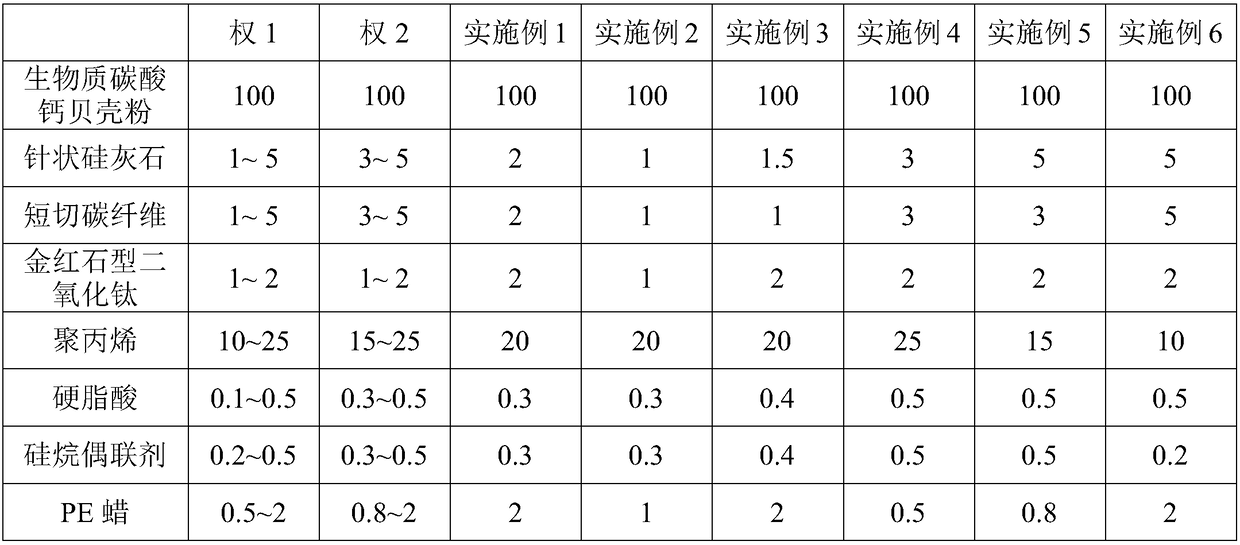

Embodiment 1

[0045] (1) Weigh respectively 2 parts of acicular wollastonite, 2 parts of chopped carbon fiber, 2 parts of rutile titanium dioxide, and 100 parts of shell powder. The above materials are placed in a high-speed mixer for high-speed mixing and dispersion. The mixing time is 40 minutes. The mixing speed is 800 rpm and the mixing temperature is 120°C to obtain dispersed powder A;

[0046] (2) Place the dispersed powder obtained in step (1) with 0.3 parts of stearic acid and 0.3 parts of silane KH560 in a high-speed mixer for high-speed mixing and modification. The mixing time is 30 minutes, and the mixing speed is 800 rpm. The mixing temperature is 120°C to obtain modified powder B;

[0047] (3) Put the modified powder B obtained in step (2) with 20 parts of polypropylene and 2 parts of PE wax in a high-speed mixer for high-speed mixing, the mixing time is 20 minutes, and the mixing speed is 800 rpm. The temperature is 140°C, and after mixing evenly, it is granulated by twin-scr...

Embodiment 2

[0049] (1) Weigh 1 part of acicular wollastonite, 1 part of chopped carbon fiber, 1 part of rutile titanium dioxide, and 100 parts of shell powder, and place the above materials in a high-speed mixer for high-speed mixing and dispersion. The mixing time is 40 minutes , with a mixing speed of 800 rpm and a mixing temperature of 120°C to obtain a dispersed powder A;

[0050](2) Place the dispersed powder obtained in step (1) with 0.3 parts of stearic acid and 0.3 parts of silane KH570 in a high-speed mixer for high-speed mixing and modification. The mixing time is 30 minutes, and the mixing speed is 800 rpm. The mixing temperature is 130°C to obtain modified powder B;

[0051] (3) Place the modified powder obtained in step (2) with 20 parts of polypropylene and 1 part of PE wax in a high-speed mixer for high-speed mixing, the mixing time is 20 minutes, the mixing speed is 800 rpm, and the mixing temperature The temperature is 150°C, and after mixing evenly, it is granulated by ...

Embodiment 3

[0053] (1) Weigh 1.5 parts of acicular wollastonite, 1 part of chopped carbon fiber, 2 parts of rutile titanium dioxide, and 100 parts of shell powder. The above materials are placed in a high-speed mixer for high-speed mixing and uniform dispersion. The mixing time is 30 Minutes, the mixing speed is 800 rpm, and the mixing temperature is 130°C to obtain dispersed powder A;

[0054] (2) Place the dispersed powder obtained in step (1) with 0.4 parts of surfactant stearic acid and 0.4 parts of silane KH560 in a high-speed mixer for high-speed mixing and modification. The mixing time is 30 minutes and the mixing speed is 800 rpm / min, and the mixing temperature is 120°C to obtain modified powder B;

[0055] (3) Place the modified powder obtained in step (2) with 20 parts of polypropylene and 2 parts of PE wax in a high-speed mixer for high-speed mixing, the mixing time is 20 minutes, the mixing speed is 800 rpm, and the mixing temperature The temperature is 140°C, and after mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com