Refractory metal powder, preparing method thereof and metal product

A technology of refractory metals and powders, which is applied in the direction of additive manufacturing, energy efficiency improvement, additive processing, etc., and can solve problems such as non-spherical shape and wide particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention also discloses a method for preparing refractory metal powder, which comprises the following steps:

[0034] A) hydrogenating the refractory metal ingot, the refractory metal ingot is pure niobium ingot, niobium alloy ingot, pure tantalum ingot or tantalum alloy ingot;

[0035] B) carrying out ball milling and crushing the refractory metal ingot after the hydrogenation treatment;

[0036] C) dehydrogenating the powder after ball mill crushing;

[0037] D) performing airflow shaping on the dehydrogenated powder;

[0038] E) pickling the powder obtained in step D);

[0039] F) vacuum heat-treating the powder obtained in step E), deoxidizing the vacuum-heat-treated powder, and finally pickling to obtain refractory metal powder.

[0040]In the above-mentioned process of preparing refractory metal powder, the applicant first hydrogenates the refractory metal ingot to initially break the refractory metal ingot to obtain refractory metal shavings. In the pres...

Embodiment 1

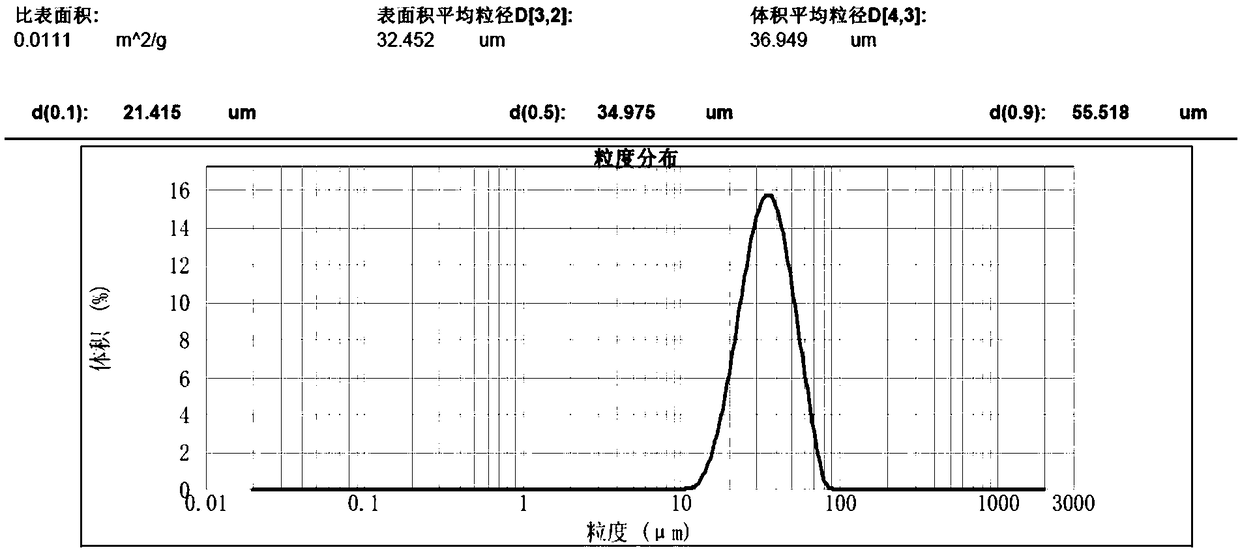

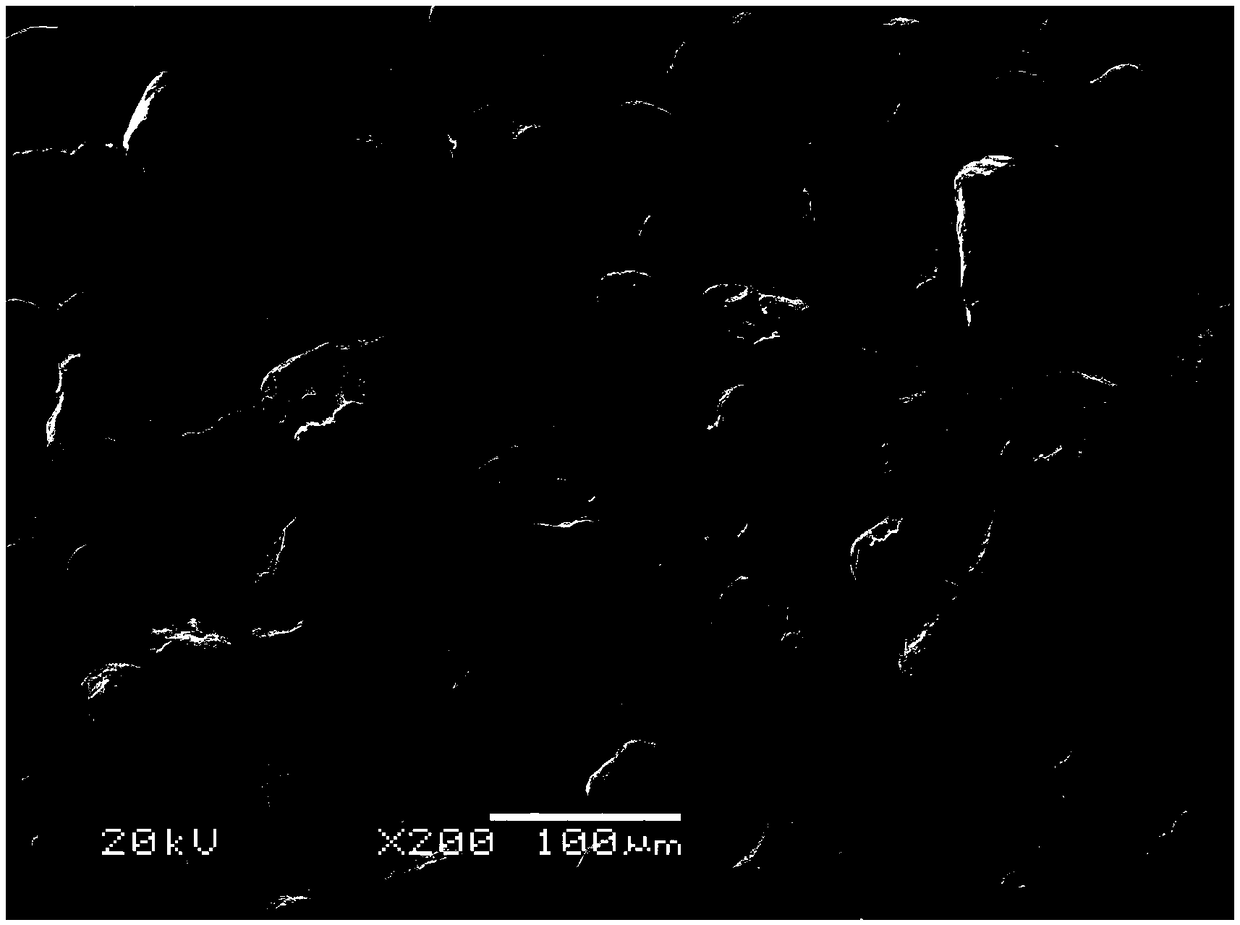

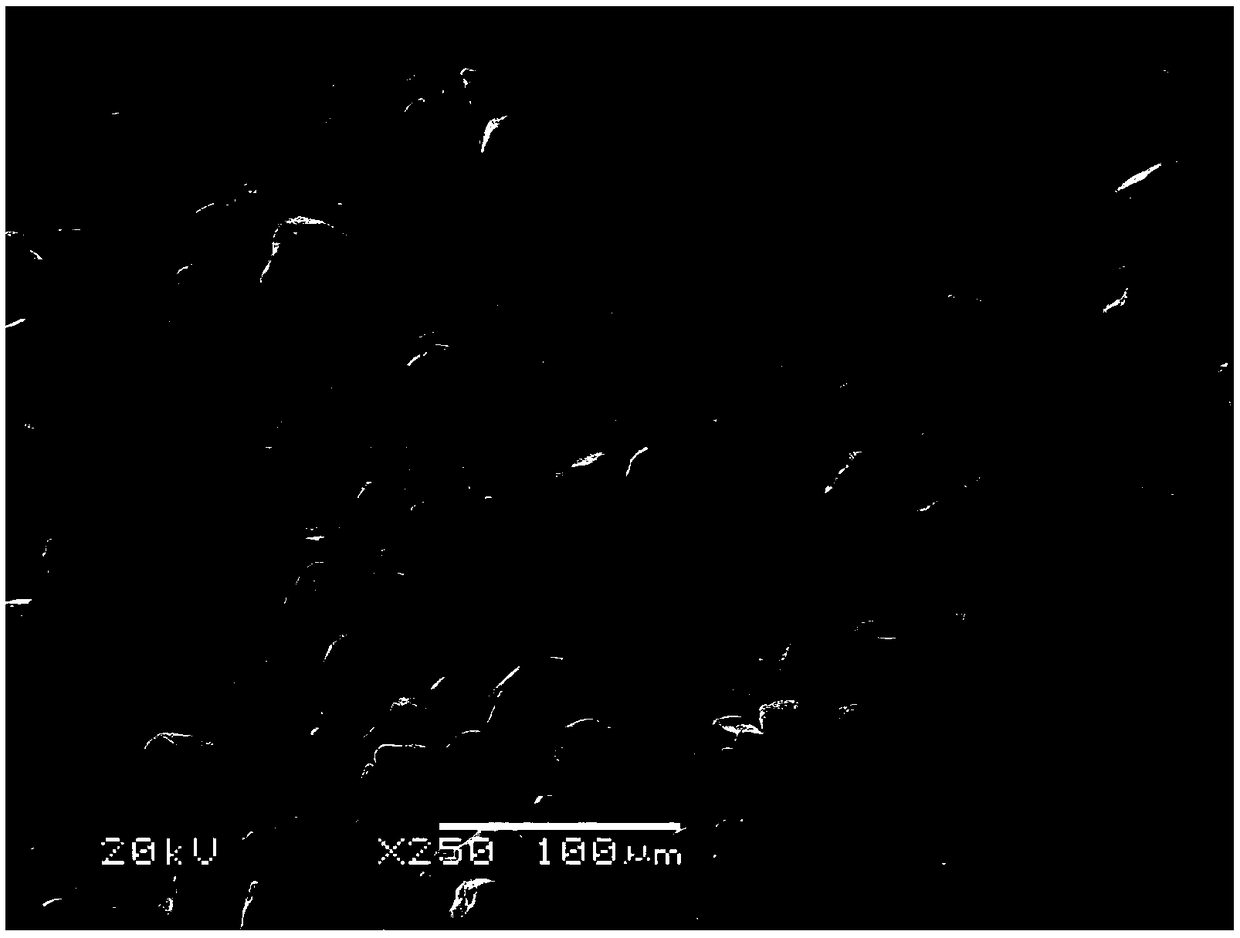

[0054] Select tantalum ingots with a tantalum content of more than 99.995%, hydrogenate and crush the tantalum ingots; ball mill and crush the tantalum shavings obtained after hydrogenation, pass the crushed materials through a 325-mesh sieve, and take the tantalum powder under the 325-mesh sieve to obtain -20kg of tantalum particles of -325 mesh; then put the tantalum particles into the reaction bomb, heat them under evacuation conditions, keep them at 800°C for about 120min, then cool them down, take them out of the furnace, and pass through 100 sieves to obtain 19.92kg of dehydrogenated tantalum powder; The dehydrogenated tantalum powder is put into the jet mill for airflow shaping. During this process, the working pressure is 6.0kg, and the working frequency of the first and second stages is 30HZ and 30HZ respectively. Powder 3.84kg; HNO 3 Mixed acid with HF (HNO 3 , HF and water volume ratio are 4:1:20) pickling to remove metal impurities, drying and sieving to obtain ta...

Embodiment 2

[0058] Select tantalum ingots with a tantalum content of more than 99.995%, hydrogenate and crush the tantalum ingots; ball mill and crush the hydrogenated tantalum shavings, pass the crushed materials through a 400-mesh sieve, and take the tantalum powder under the 400-mesh sieve to obtain -400 The target tantalum particles are 20kg; then put the tantalum particles into the reaction bomb, heat them under evacuation conditions, keep them at 750°C for about 120min, then cool them down, take them out of the furnace, and pass through 100 sieves to obtain 19.87kg of dehydrogenated tantalum powder; The final tantalum powder is put into the airflow mill for airflow shaping. In this process, the working pressure is 6.5kg, and the working frequency of the first-level and second-level is 40HZ and 40HZ respectively. kg; the primary tantalum powder after airflow shaping uses HNO 3 Mixed acid with HF (HNO 3 , HF and the volume ratio of water are 4:1:20) pickling to remove metal impuritie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com