Process adopting hydrogenated metal for diffusion bonding of tungsten and steel of fusion reactor material

A metal diffusion and fusion reactor technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problem of high yield strength of titanium metal, achieve the effect of reducing yield strength, lowering welding temperature, and facilitating stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

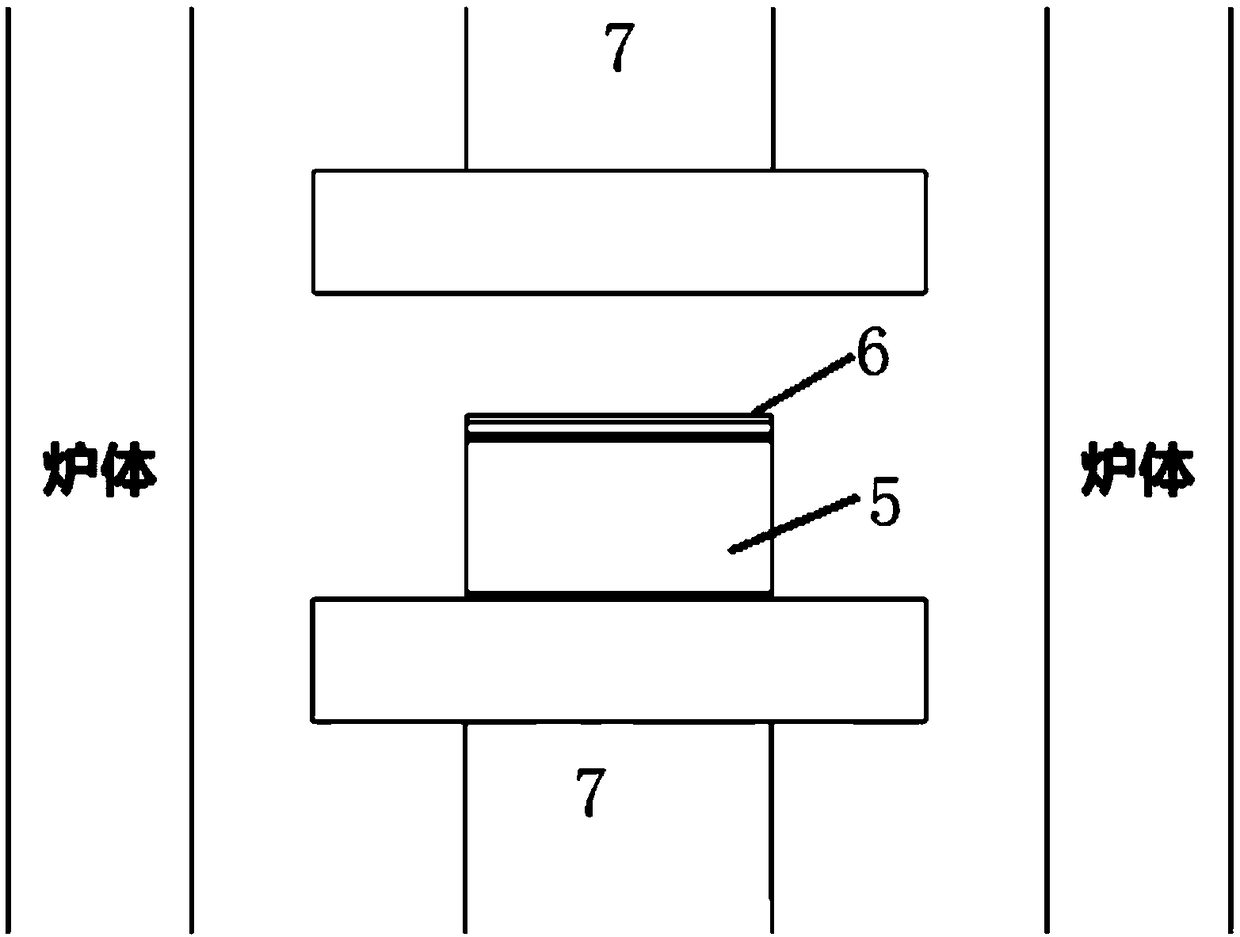

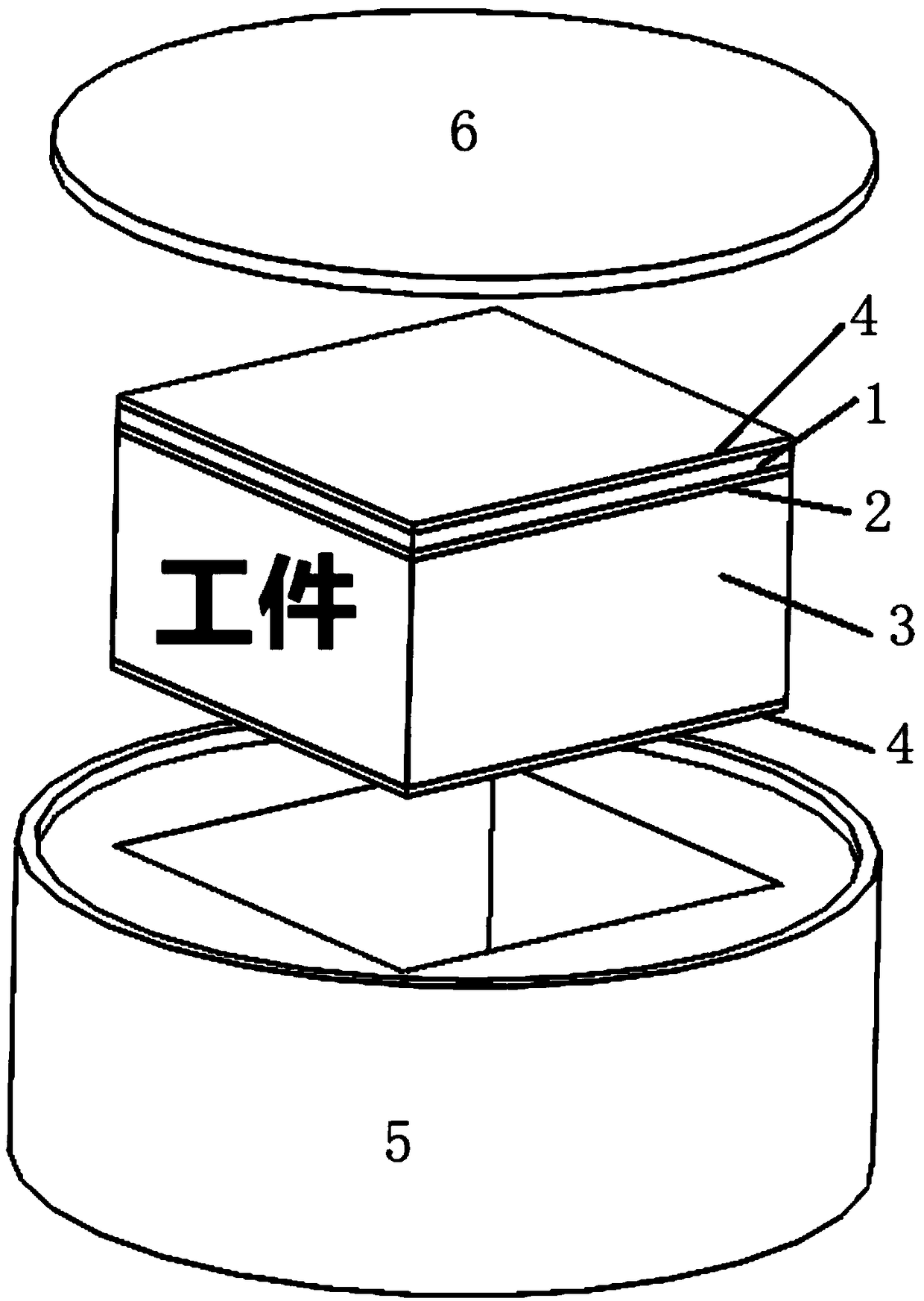

[0038] Taking the China Fusion Engineering Test Reactor (CFETR) water-cooled ceramic cladding (WCCB) first wall (FW), tungsten and low-activation steel vacuum thermocompression welding as an example for further explanation.

[0039] Such as figure 1 and figure 2 As shown, a manufacturing process suitable for the connection between tungsten and steel of the first wall part of the fusion reactor, the process steps are:

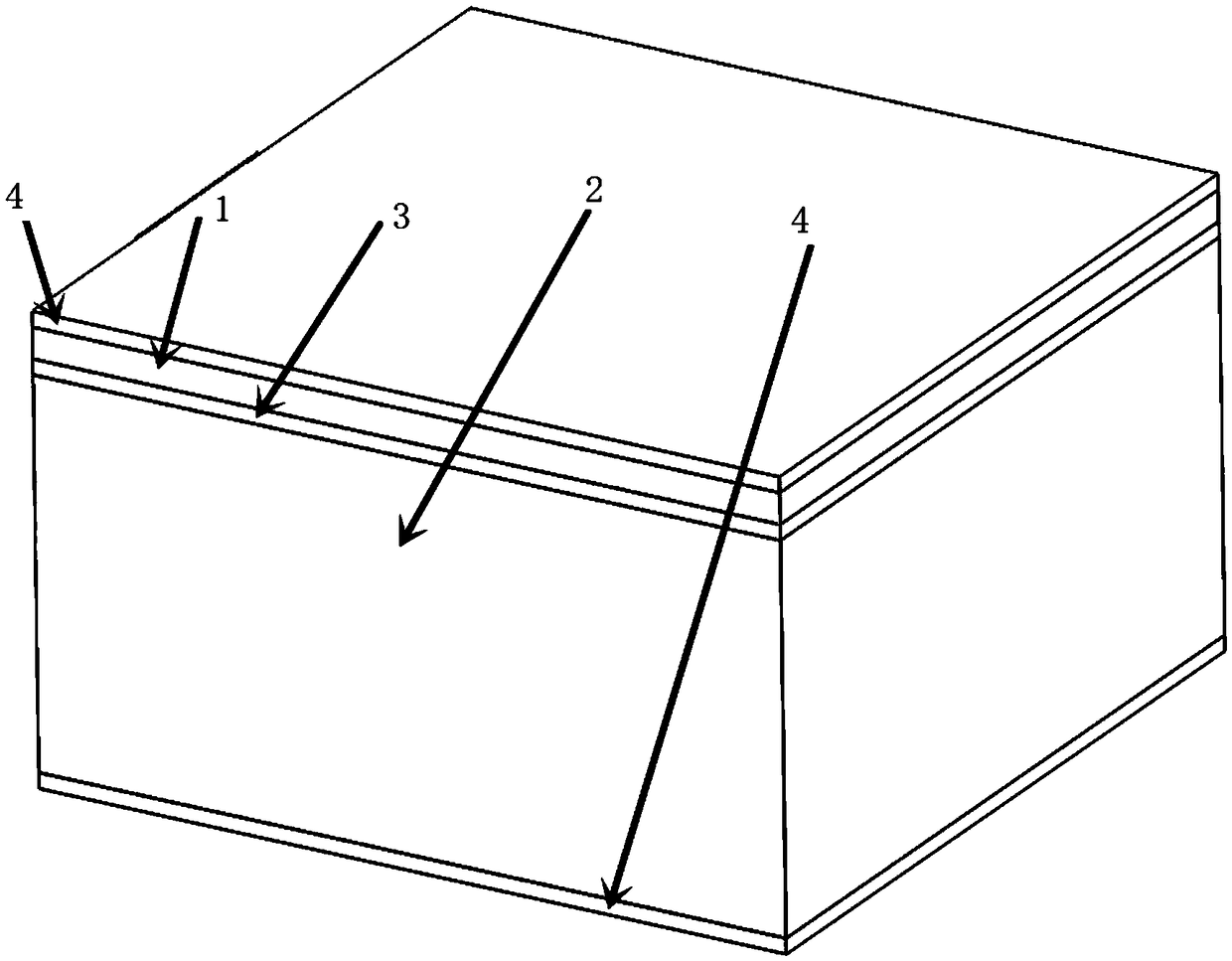

[0040] 1) Machining the tungsten sheet 1 required for vacuum thermocompression welding, the steel block 2 and the transition layer metal pure titanium sheet 3 to be hydrogenated, such as figure 1 shown. The surface roughness of the surface to be welded was finely ground to ≤ Ra 0.8 μm, and the sample was placed in an acetone solution at 35°C for 30 minutes to remove surface grease and dirt. After taking it out, it was vacuum-packed for use.

[0041] 2) Vacuum annealing treatment is carried out on the processed titanium sheet 3, and the vacuum degree is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com