Method and device for removing organic matters in aluminum oxide mother liquor with assistance of aluminum ash sintering process

A sintering method and alumina technology, which is applied in the field of metallurgical aluminum production, can solve problems such as difficult operation, difficult regeneration, and high cost of additive consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

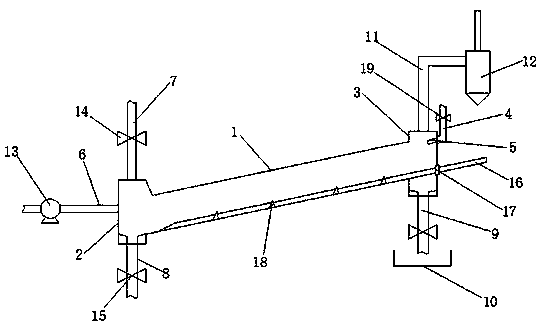

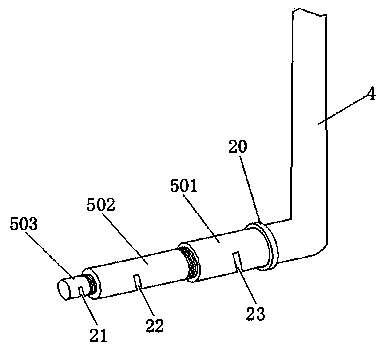

[0046] Such as figure 1 As shown, the device for synergistically removing organic matter in alumina mother liquor by aluminum ash sintering method includes a rotary kiln 1, a cyclone separator 12, and a cooler. One end of the rotary kiln 1 is the kiln head 2, and the other end is the kiln tail 3. The discharge port is connected to the feed port of the cooling machine through the cooling pipe 8, the discharge port of the kiln tail 3 is connected to the feed port of the cyclone separator 12 through the tail gas recovery pipe 11, the rotary kiln 1 is set obliquely, and the kiln head 2 is located in the kiln Below the tail 3, the fuel inlet of the kiln head 2 is connected to the fuel pipe 7, the air inlet of the kiln head 2 is connected to the air pipe 6, the raw meal inlet of the kiln tail 3 is connected to the raw meal pipe 4, and the raw meal pipe 4 is located at the kiln tail One end in 3 is provided with shower head 5.

[0047] In use, the raw slurry, fuel and air are passed...

Embodiment 2

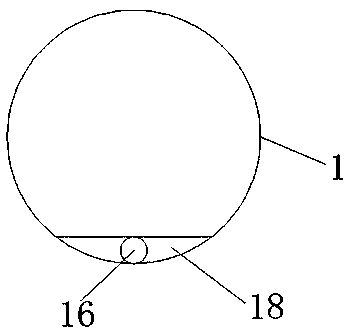

[0058] Based on Example 1, such as image 3 As shown, a movable rod 16 is arranged at the bottom of the rotary kiln 1, and a scraper 18 is arranged on the movable rod 16, and one end of the movable rod 16 passes through the kiln tail 3. The other end of the movable rod 16 is located in the rotary kiln 1 and is tapered. The bottom of the scraper 18 is in contact with the inner wall of the rotary kiln 1 , and the end of the scraper facing the kiln head 2 is tapered. The kiln tail 3 is provided with a sealing ring 17, and the movable rod 16 passes through the sealing ring 17.

[0059] In use, a large amount of oxidized intermediate products are precipitated during the entire reaction of the combustion method to remove the organic matter in the alumina mother liquor, which will be adsorbed on the inner wall of the rotary kiln. If it is not cleaned for a long time, the problem of rotary kiln blockage will easily occur. , so that it can scrape off the oxide at the bottom of the inn...

Embodiment 3

[0062] Based on Example 1, the outlet at the bottom of the kiln tail 3 is connected to the ash collection pipe 9, the fuel pipe 7 is provided with a first control valve 14, the air delivery pipe 6 is provided with a fan 13, and the cooling pipe 8 is provided with a second control valve. The control valve 15 is provided with a third control valve 19 on the raw material pipe 4 .

[0063] During use, the ash collecting pipe provided can recycle the α-alumina produced by the reaction, and the flow of each pipe can be controlled through the provided first control valve, second control valve and third control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com