Method for degrading phenol pollutant by utilizing ferroferric oxide nanoparticle reinforced anaerobic reactor

An anaerobic reactor and ferroferric oxide technology, which is applied in chemical instruments and methods, water pollutants, anaerobic digestion treatment, etc., can solve the problem of poor removal effect of phenolic pollutants, and achieve the promotion of anaerobic methane production process, increase the removal rate, and promote the effect of the methanogenic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

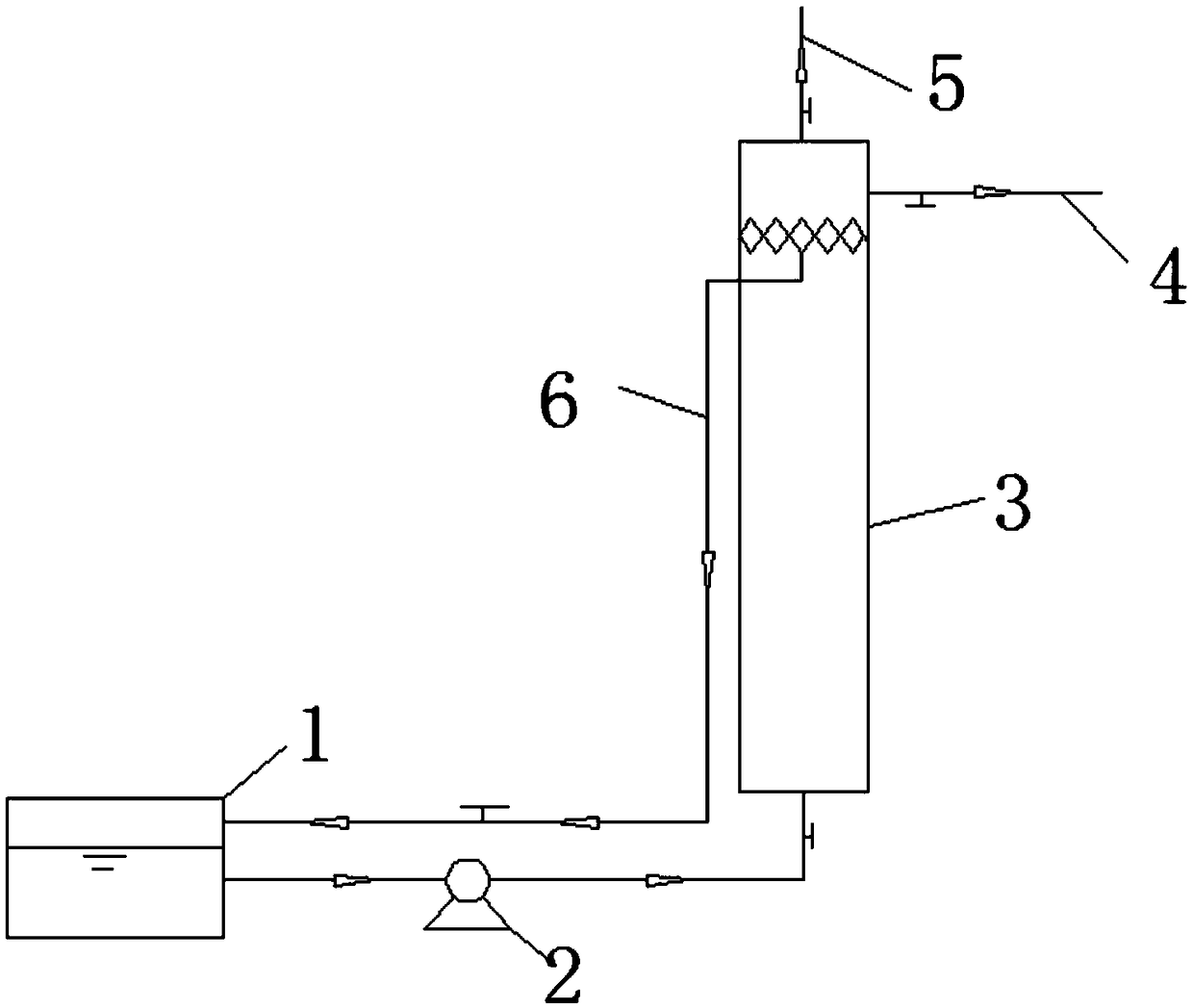

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: this embodiment is a kind of method that utilizes iron ferric oxide nanoparticles to strengthen the anaerobic reactor to degrade phenol pollutants, specifically according to the following steps:

[0017] 1. Use anaerobic granular sludge as the initial inoculation mud source, add wastewater to be treated into the anaerobic reactor, keep the temperature of the anaerobic reactor at 34°C-37°C, and the hydraulic retention time of the anaerobic reactor at 36h , and keep the pH of the anaerobic reactor at 7.0 to 7.4; the waste water to be treated is coal gas waste water with a COD of 1700 mg / L to 2100 mg / L and a total phenol concentration of 475 mg / L to 505 mg / L; anaerobic The concentration of the initial inoculum source in the oxygen reactor is 12g / L~15g / L;

[0018] Two, in the anaerobic reactor, add iron ferric oxide nanoparticles, the ratio of the mass concentration of the iron ferric oxide nanoparticles added in the anaerobic reactor and the COD co...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the pH of the anaerobic reactor is kept at 7.0-7.4 by adding sodium bicarbonate and hydrochloric acid solution. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the concentration of the initial inoculum source in the anaerobic reactor in step 1 is 13 g / L. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com