Method for synthesizing 3,3-dimethyl butyraldehyde

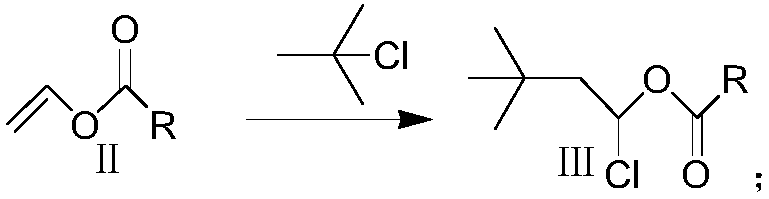

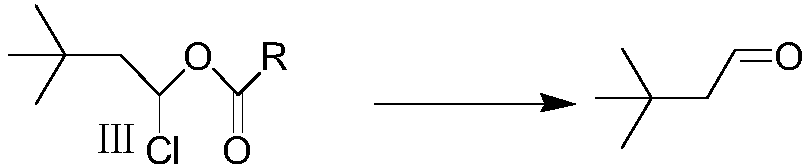

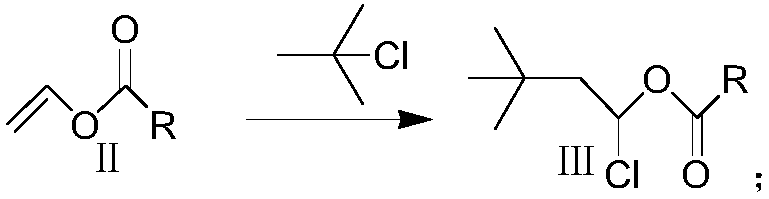

A technology of dimethylbutyraldehyde and compounds, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carbonyl compounds by hydrolysis, etc., can solve the problems of complex post-treatment, large waste water generation, expensive raw materials, etc., and achieve the improvement of crude products and The effect of finished product yield, reduction of reaction impurities, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a 2000ml four-neck flask, put into 400.0g of dichloromethane and 20.0g of solid AlCl after the thermometer is fully replaced with nitrogen. 3 / Al 2 o 3 , cooled to -10°C, then slowly added 203.6g of tert-butyl chloride (2.2mol) dropwise, and the dropwise addition was completed within 1 hour, then began to dropwise add 200g of vinyl propionate (2mol), within 1 hour after the dropwise addition was completed, keep the temperature After reacting for 2 hours, the catalyst was removed by filtration, and the catalyst was recovered. Then the organic layer was distilled under reduced pressure to remove low boiling point substances to obtain an intermediate, 700g NaOH (15%) aqueous solution was added to the intermediate, heated to 110°C for reflux and hydrolyzed for 10 hours to obtain the crude product 3,3-dimethylbutyraldehyde , the crude product was rectified to obtain 3,3-dimethylbutyraldehyde with a purity of 99.0%, and a yield of 80%.

Embodiment 2

[0028] In a 2000ml four-necked flask, put into 400.0g of dichloroethane and 59.0g of solid TiO after the thermometer is fully replaced with nitrogen. 2 / SO 4 2- , cooled to -8°C, then slowly added 185.1g of tert-butyl chloride (2mol) dropwise, and the dropwise addition was completed within 1 hour, and then began to dropwise add 258.3g of vinyl acetate (3mol), and after the dropwise addition was completed within 1 hour, the insulation reaction After 2 hours, the catalyst was removed by filtration, and the catalyst was recovered. Then the organic layer was distilled under reduced pressure to remove low-boiling substances to obtain an intermediate, and 2.0 g of catalyst amberlyst35 and 200.0 g of deionized water were added to the intermediate, heated to 90° C., refluxed and hydrolyzed for 2 hours. After the catalyst was filtered, the crude product 3,3- Dimethylbutyraldehyde, the crude product is rectified to obtain 3,3-dimethylbutanal with a purity of 99.1%, and the yield is 83...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com