Flue gas cooling and heat exchanger with cooling device for desulfurization flue opening

A refrigeration device and flue gas cooling technology, applied in steam/steam condensers, climate sustainability, greenhouse gas reduction, etc., can solve problems such as smog pollution that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

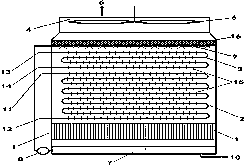

[0018] Such as figure 1 As shown, the flue gas cooling heat exchanger with a refrigeration device at the desulfurization flue mouth of the present invention involves the operation and circulation of three parts of the fluid. Carry out preliminary condensation, then enter the cryogenic condenser (3) for further cooling, and then enter the smoke exhaust tower (5) from the upper part of the cryogenic condenser through the flue gas outlet (4) to be discharged, and the whole process is carried out by the upper axial flow fan (6) Provide power, the water vapor in the wet flue gas is condensed and collected to the water collector (7) at the bottom, and part of it is transported to the water mist nozzle (9) by the circulating water pump (8) for cleaning the outer wall of the heat exchanger tube Regular dust removal is carried out, and the other part is transported to the water treatment system (10), and the treated water can enter other parts of the system for water replenishment; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com