NC (Nitrocellulose Filter) membrane and production technology for preparing NC membrane by lineation

A production process and film-scribing technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as low repeatability and high coefficient of variation, and achieve the effects of improving accuracy, reducing diffusion, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment relates to the production of scribed NC film, comprising the following steps:

[0026] a. Filming and drying after filming:

[0027] a1. Film marking: Take the NC film roll and place it on the reel, and then pass through the film marking device to mark or spray the antibody solution diluted to the required concentration on the NC film;

[0028] a2. Drying after scribing: While scribing the back end of the NC film, the front end of the NC film that has been scribed immediately enters the drying tower that has been preheated to a drying temperature of 35-40°C in advance, that is, the scribing is running in a continuous state , Drying process after scribing film, wind up after drying or continue to carry out follow-up processing in continuous operation state;

[0029] The running time of the scribing and drying process after scribing is controlled within 2 to 4 minutes;

[0030] b. Membrane sealing and drying process after sealing

[0031] b1. Membrane s...

Embodiment 21

[0039] This example involves the verification of the performance of the reagent strips produced by the NC membrane produced by the process described in Example 1. The formula of the blocking solution used in the production process of the NC membrane is as follows: the blocking solution consists of PEG4000 as the sealing component, Surfynol 485 as the surfactant component, Pluranic L64 was prepared by dissolving in PB solution with pH 7.0 and 50mM and adjusting the pH of the blocking solution to 7.0; the mass percentages of PEG4000, Surfynol 485 and Pluranic L64 in the blocking solution were 0.5%, 0.6%, 0.2% respectively %.

[0040] The present embodiment and follow-up examples and comparative examples all take BNP reagent strips as an example (the detection range of different reagent strips is different, such as the detection range of BNP reagent strips is 6pg / ml~4000pg / ml, the detection range of cTnI reagent strips is 0.05ng / ml~30ng / ml), the performance experiment operation i...

Embodiment 22

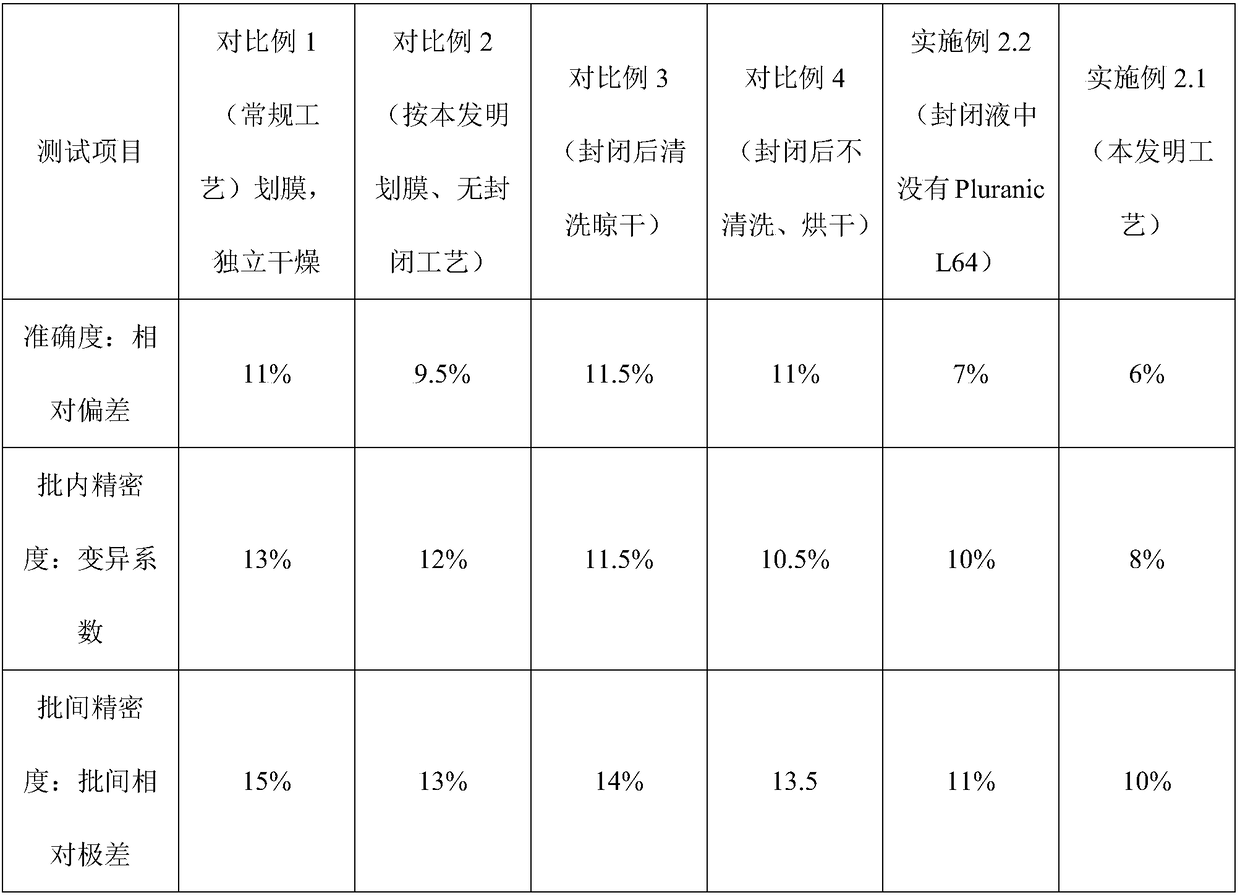

[0047] This example relates to the influence of the composition of the blocking solution on the performance of the reagent strip.

[0048] The reagent strips were prepared by using the NC film obtained by the substantially same production process as in Example 2.1, and the performance of the reagent strips was tested (the test method was the same as in Example 2.1). The difference between this reagent strip and the reagent strip of Example 2.1 is that the blocking solution used in the production process is different, and the blocking solution consists of blocking component PEG4000, surfactant component Surfynol 485, dissolved in pH7.0, 50mM PB solution and adjust the pH of the blocking solution to 7.0; the mass percentages of PEG4000 and Surfynol 485 in the blocking solution are 0.5% and 0.6% respectively. The test results are shown in the table below:

[0049] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com