Flexible substrate-go-metal nanowire composite transparent conductive film and preparation method thereof

A technology of transparent conductive film and metal nanowire, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems such as the decrease of electrode conductivity and the decrease of optical transmittance of metal nanowire electrode, and achieve Reduced peak-to-valley roughness, avoiding low conductivity, and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

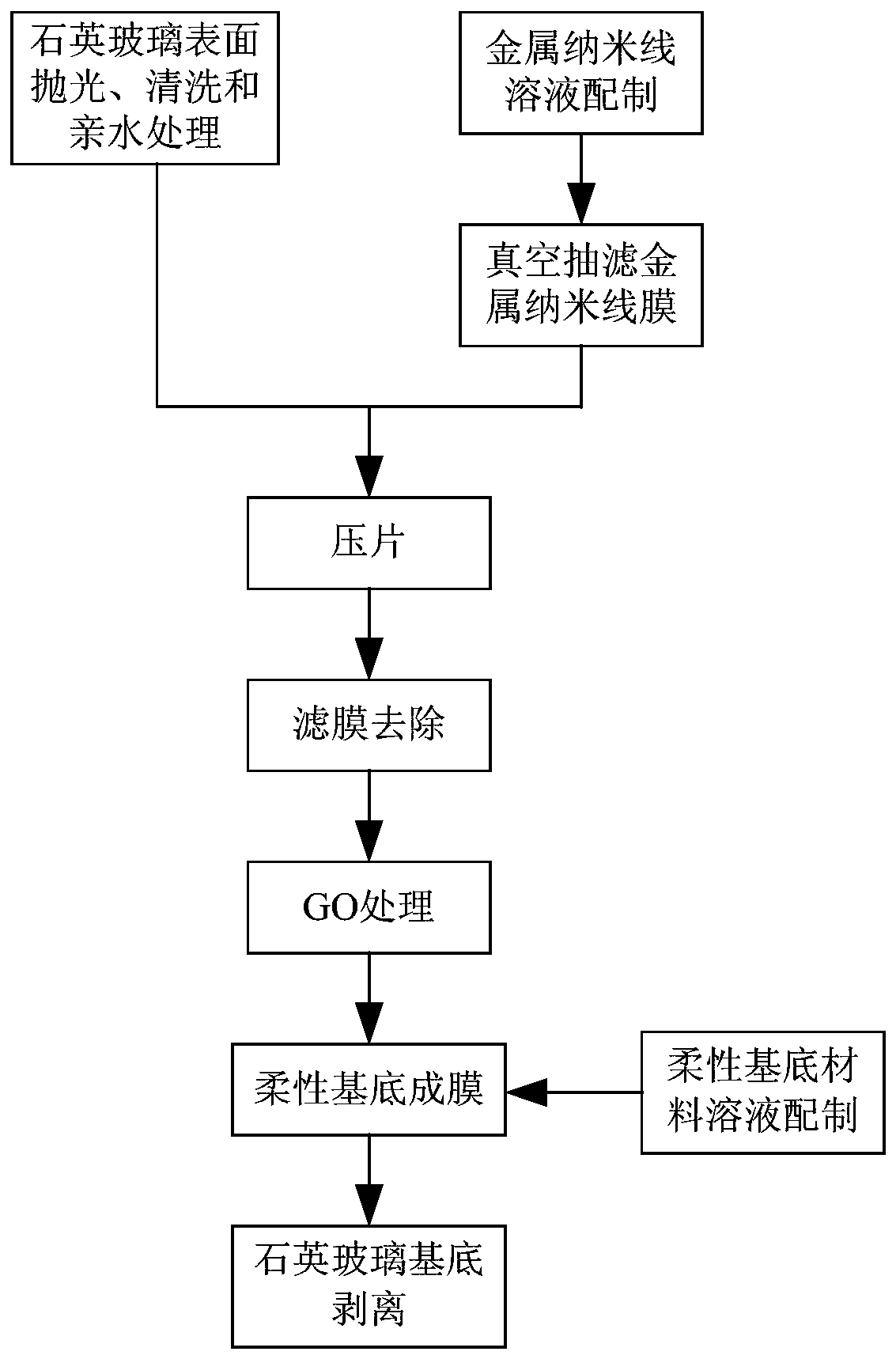

[0042] Please refer to figure 1 As shown, the present invention provides a method for preparing a flexible substrate-GO-metal nanowire composite transparent conductive film, comprising the following steps:

[0043] Surface treatment of quartz glass substrate: use quartz glass as the initial substrate of metal nanowire composite transparent conductive film, and perform surface polishing, surface cleaning and surface hydrophilic treatment on the quartz glass substrate. Specifically, as the initial substrate of the metal nanowire composite transparent conductive film, the quartz glass substrate needs to meet the requirements in terms of surface flatness, cleanliness, and hydrophilicity. Therefore, the entire surface treatment process of the quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com