Novel microwave GaN transistor with high electron mobility

A technology with high electron mobility and high GaN, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of device output power, power added efficiency, unsatisfactory transistor withstand voltage, and narrow transconductance saturation region. , to achieve the effect of reducing the influence, reducing the current collapse effect, and improving the frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The structure of the improved GaN high electron mobility transistor is as follows.

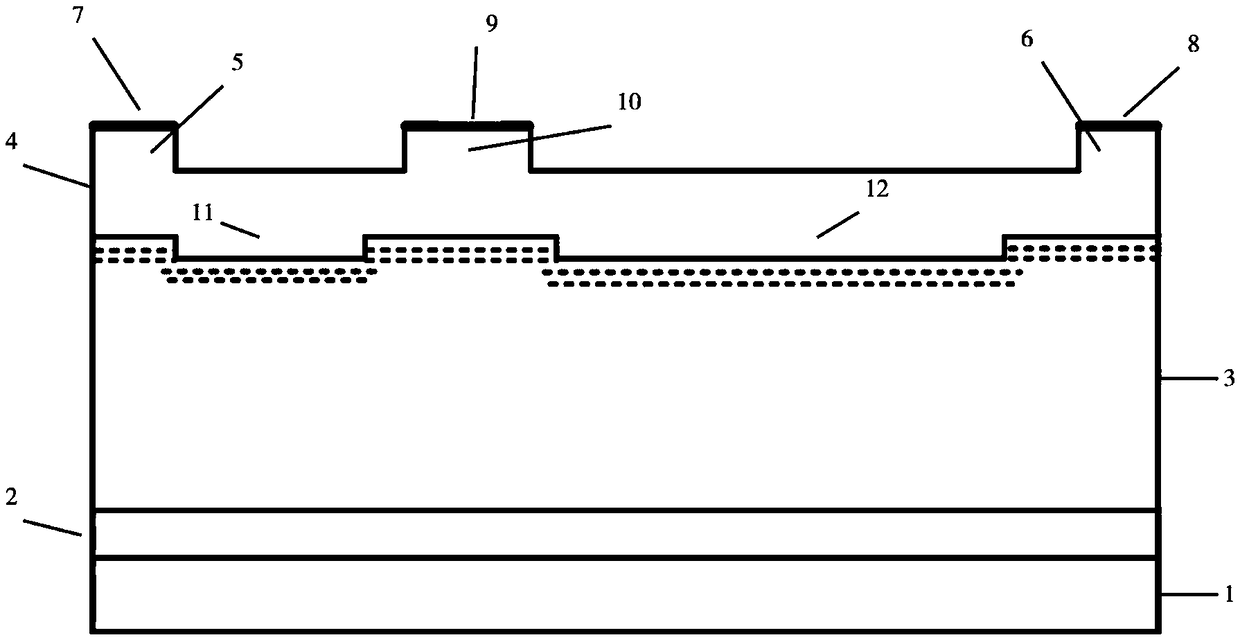

[0031] exist figure 1 Among them, the microwave gallium nitride high electron mobility transistor with high gate and multiple recessed buffer layers of the present invention has a structure from bottom to top including a semi-insulating substrate 1, an aluminum nitride nucleation layer 2, and a gallium nitride buffer layer 3 and an AlGaN barrier layer 4, a source cap layer 5 and a drain cap layer 6 on the AlGaN barrier layer, the upper surface is respectively a source electrode 7 and a drain electrode 8, between the source electrode and the drain electrode, And the gate electrode 9 is formed on the side close to the source. In the transistor, the upper surface of the high gate 10 is 5nm higher than the bottom surface, and the upper surface of the gallium nitride buffer layer directly below the source and the gate has a recess formed The left recessed region 11 has a right recessed regi...

Embodiment 2

[0037] In this embodiment, the height of the gate electrode 9 is 4 nm, the thickness of the recessed buffer layer 11 is 2 nm, and the thickness of the recessed buffer layer (12) is 2 nm.

[0038] The remaining technical solutions of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0040] In this embodiment, the height of the gate electrode 9 is 3 nm, the thickness of the left recessed region 11 is 1 nm, and the thickness of the right recessed region 12 is 1 nm.

[0041] The remaining technical solutions of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com