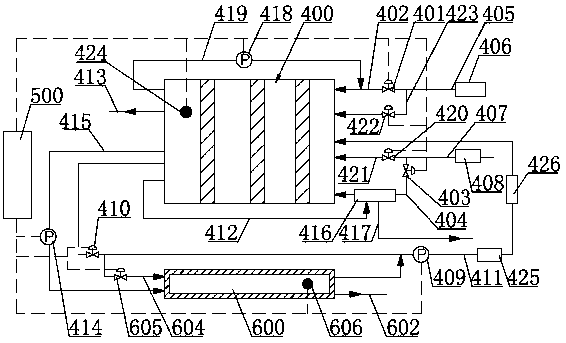

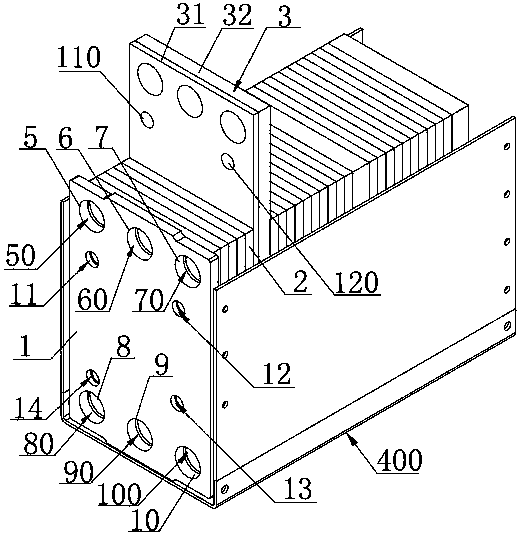

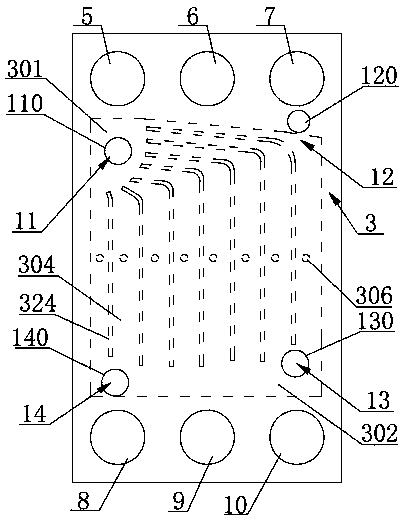

Power system of fuel cell car with ultra-low-temperature cold starting function

A fuel cell and power system technology, applied in fuel cell parts, fuel cells, fuel cell additives, etc., can solve the problems of slow start, failed start, difficult start, etc., to ensure work stability and avoid large consumption , the effect of short cold start time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] Environmental conditions: specific heat of graphite 710 J / (kg K); calorific value of hydrogen 1.4×10 8 J / kg; battery stack mass 200kg; ambient temperature -30°C; temperature after heating up 0°C; heat dissipation rate 5%.

[0041] Hydrogen consumption = (temperature after heating - ambient temperature) × specific heat of graphite × mass of battery stack ÷ calorific value of hydrogen × (1+ heat dissipation rate).

[0042] Hydrogen consumption=30×710×200÷(1.4×10 8 )×1.05=0.032kg.

example 2

[0044] Environmental conditions: ambient temperature -20°C; temperature after heating up 0°C; hydrogen consumption flow rate 0.048kg / min; graphite specific heat 710 J / (kg K); hydrogen calorific value 1.4×10 8 J / kg; battery stack mass 200kg; heat dissipation rate 5%.

[0045] Among them: the hydrogen consumption flow is determined according to the hydrogen supply capacity of the hydrogen supply system for the fuel cell system, and the working hydrogen consumption under the rated power of the fuel cell is determined, taking a 36kw fuel cell as an example.

[0046] Hydrogen consumption = (temperature after heating - ambient temperature) × specific heat of graphite × mass of battery stack ÷ calorific value of hydrogen × (1+ heat dissipation rate).

[0047] Hydrogen consumption=20×710×200÷(1.4×10 8 )×1.05=0.022kg.

[0048] Cold start time = hydrogen consumption ÷ hydrogen flow.

[0049] Cold start time=0.022÷0.048=0.46 min=28 s.

[0050] That is: from the ambient temperature -...

example 3

[0052] Environmental conditions: ambient temperature -10°C; temperature after heating up 0°C; hydrogen consumption flow rate 0.048kg / min; graphite specific heat 710 J / (kg K); hydrogen calorific value 1.4×10 8 J / kg; battery stack mass 200kg; heat dissipation rate 5%.

[0053] Among them: the hydrogen consumption flow is determined according to the hydrogen supply capacity of the hydrogen supply system for the fuel cell system, and the working hydrogen consumption under the rated power of the fuel cell is determined, taking a 36kw fuel cell as an example.

[0054] Hydrogen consumption = (temperature after heating - ambient temperature) × specific heat of graphite × mass of battery stack ÷ calorific value of hydrogen × (1+ heat dissipation rate).

[0055] Hydrogen consumption=10×710×200÷(1.4×10 8 )×1.05=0.011kg.

[0056] Cold start time = hydrogen consumption ÷ hydrogen flow.

[0057] Cold start time=0.011÷0.048=0.23 min=14 s.

[0058] That is: from the ambient temperature -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com