Anti-overcharging lithium battery electrolyte, lithium battery and preparation method of lithium battery

A lithium battery, anti-overcharge technology, applied in the manufacture of electrolyte batteries, lithium batteries, secondary batteries, etc., can solve problems such as heat diffusion, battery performance degradation, battery short circuit, etc., to reduce side reactions, slow down speed, increase The effect of moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

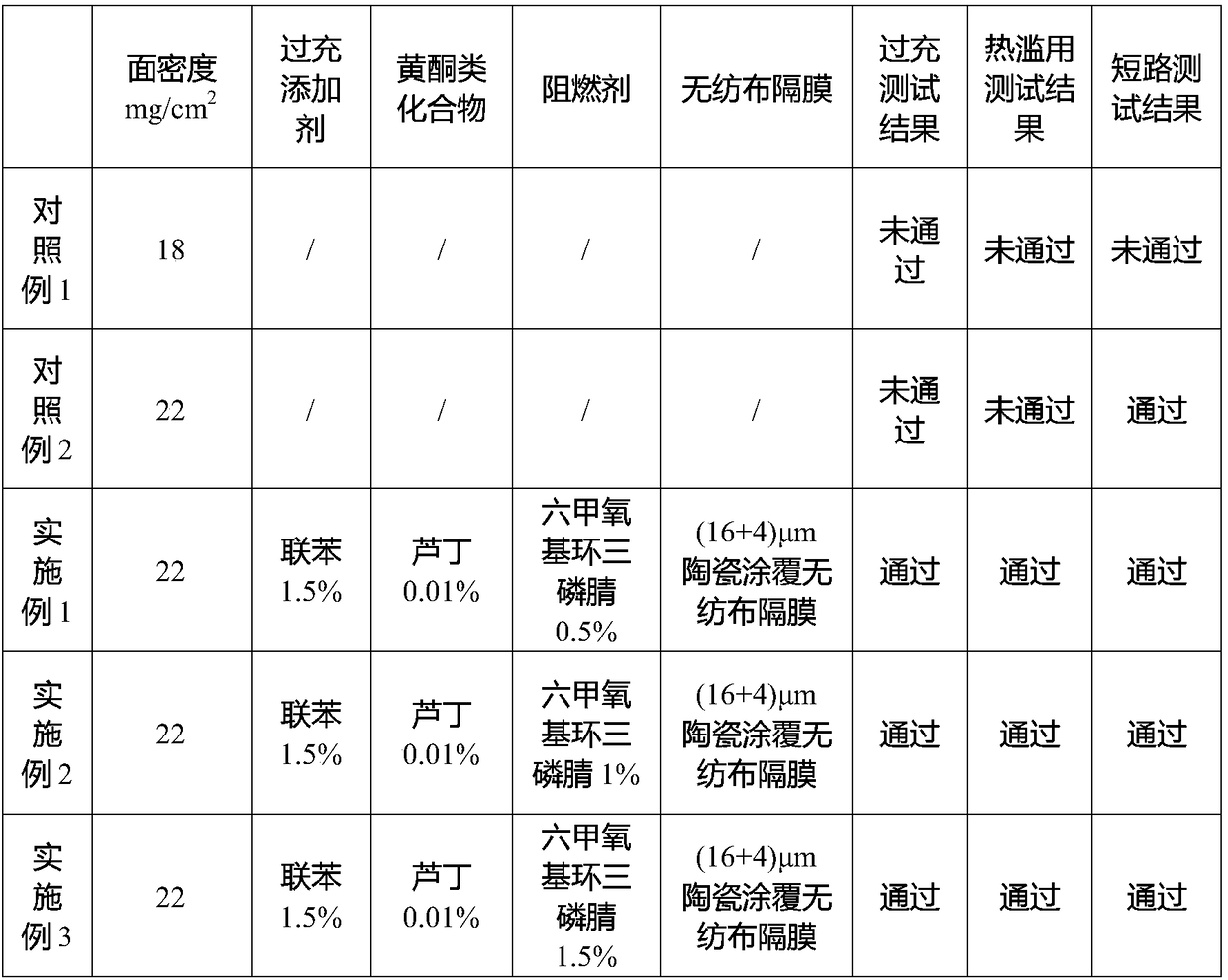

Embodiment 1

[0035] ①When coating the battery, the density of one side is 22mg / cm 2 ;

[0036] ②Complete rolling and die-cutting according to the production process of the battery cell;

[0037] ③The laminate uses (16+4)μm ceramic-coated non-woven diaphragm;

[0038] ④ Carry out spot welding packaging and baking according to the cell production process;

[0039] ⑤Electrolyte preparation:

[0040] The electrolyte uses 1.1mol / L lithium hexafluorophosphate as the solute, EC, EMC, and DMC as the organic solvent at a volume ratio of 1:1:1, and adds biphenyl (1.5%), a derivative of benzene, and rutin (0.02%), a flavonoid compound. , and flame retardant hexamethoxycyclotriphosphazene (0.5%) as additives;

[0041] ⑥Inject the above-mentioned electrolyte into the baked cell, and complete the production of the cell according to the process.

Embodiment 2

[0043] ①When coating the battery, the density of one side is 22mg / cm 2 ;

[0044] ②Complete rolling and die-cutting according to the production process of the battery cell;

[0045] ③The laminate uses (16+4)μm ceramic-coated non-woven diaphragm;

[0046] ④ Carry out spot welding packaging and baking according to the cell production process;

[0047] ⑤Electrolyte preparation:

[0048] The electrolyte uses 1.1mol / L lithium hexafluorophosphate as the solute, and a mixture of EC, EMC, and DMC with a volume ratio of 1:1:1 as the organic solvent, and adds biphenyl (1.5%), a derivative of benzene, and rutin ( 0.04%), and flame retardant hexamethoxycyclotriphosphazene (1%) as additives;

[0049] ⑥Inject the above-mentioned electrolyte into the baked cell, and complete the production of the cell according to the process.

Embodiment 3

[0051] ①When coating the battery, the density of one side is 22mg / cm 2 ;

[0052] ②Complete rolling and die-cutting according to the production process of the battery cell;

[0053] ③The laminate uses (16+4)μm ceramic-coated non-woven diaphragm;

[0054] ④ Carry out spot welding packaging and baking according to the cell production process;

[0055] ⑤Electrolyte preparation:

[0056] The electrolyte uses 1.1mol / L lithium hexafluorophosphate as the solute, EC, EMC, and DMC as the organic solvent at a ratio of 1:1:1, and adds benzene derivatives biphenyl (1.5%), flavonoids rutin (0.05%), And flame retardant hexamethoxycyclotriphosphazene (1.5%) as additive;

[0057] ⑥Inject the above-mentioned electrolyte into the baked cell, and complete the production of the cell according to the process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com