Multipurpose breastfeeding chair containing laundering-durable cover

A washing-resistant and covering technology, which is applied in the field of multi-purpose breastfeeding chairs, can solve the problems of the covering including poor washing-resistant covering and poor comfort, and achieves reduced fiber damage rate and weight loss rate, high comfort and good stain resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

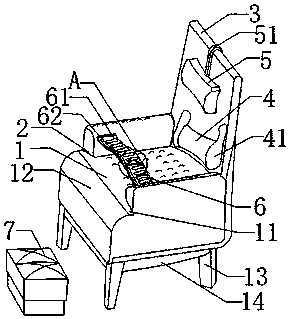

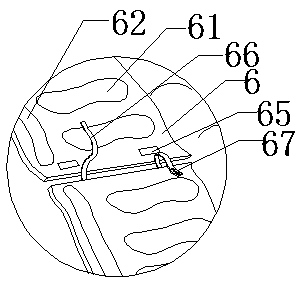

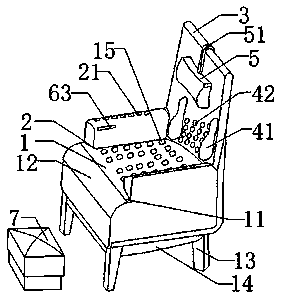

[0029] Such as Figure 1-5As shown in , a multi-purpose breastfeeding chair comprising a washable cover, including a seat 1, a chair back 3, an armrest 2, a footrest 7, and a cover set on the chair body and the footrest 7 (not marked in the figure Out), wherein the cover on the connecting belt 6 is cylindrical, and the other parts are set according to the corresponding positions; the bottom of the seat 1 and the pedal 7 is provided with a wooden frame 14, and four supporting feet 13 are connected under the wooden frame 14; Several seat airbags 15 are evenly distributed on the seat 1, and several armrest airbags 21 are evenly distributed on the upper surface of the armrest 2; The airbag 42 is provided with a rectangular lumbar pad 4, the part of the rectangular lumbar pad 4 except the lumbar pad airbag 42 is filled with a sponge with a density of 30, and the two sides of the rectangular lumbar pad 4 are provided with vertically arranged lumbar pad side ears 41; The position on...

Embodiment 2

[0039] Wherein, the fabric of the overlay is formed by wrapping and weaving cotton fiber, pearl fiber, fine denier acrylic and chemical fiber filament and processed by finishing liquid, and the weight ratio of cotton fiber, pearl fiber, fine denier acrylic and chemical fiber filament is 6:2:3:2, the finishing solution is made of the following components by weight: 8 parts of polybutyl acrylate, 4 parts of chitosan, 1 part of zinc silicate, 1.2 parts of polyvinylpyrrolidone, trioctyl citrate 1.4 parts, 2 parts of cyclodextrin, 0.2 parts of 2,2-dimethylolpropionic acid, 0.08 parts of α-cyanoacrylate, the mass concentration of the finishing solution is 8g / L;

[0040] The finishing process is to place the fabric in the finishing solution at a temperature of 20°C, soak it for 2 hours, stack it for 6 hours after completion, and dry it.

[0041] Wherein, the count of the cotton fiber is 5000 m / g, the fineness of the pearl fiber is 16tex; the fine denier acrylic is a yarn of 12tex, an...

Embodiment 3

[0046] Wherein, the fabric of the overlay is formed by wrapping and weaving cotton fiber, pearl fiber, fine denier acrylic and chemical fiber filament and processed by finishing liquid, and the weight ratio of cotton fiber, pearl fiber, fine denier acrylic and chemical fiber filament is 6:2:3:2, the finishing solution is made of the following components by weight: 12 parts of polybutylacrylate, 3 parts of chitosan, 3 parts of zinc silicate, 0.8 parts of polyvinylpyrrolidone, acetyl trioctyl citrate 1.6 parts of ester, 1 part of cyclodextrin, 0.6 part of 2,2-dimethylolpropionic acid, 0.04 part of α-cyanoacrylate, the mass concentration of the finishing solution is 16g / L;

[0047] The finishing process is to place the fabric in the finishing solution at a temperature of 28°C, soak for 2 hours, stack it for 4 hours after completion, and dry it.

[0048] Wherein, the count of the cotton fiber is 6500 m / g, the fineness of the pearl fiber is 15tex; the fine denier nitrile is the yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com