Curcumin solid dispersion and preparation method and application thereof

A solid dispersion, curcumin technology, applied in the application, non-active ingredient medical preparations, pharmaceutical formulas and other directions, can solve the problems of poor water solubility, low absolute bioavailability, and low blood drug concentration of curcumin preparations, and achieves Improve oral bioavailability, reduce drug dosage, lower blood sugar and resist stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

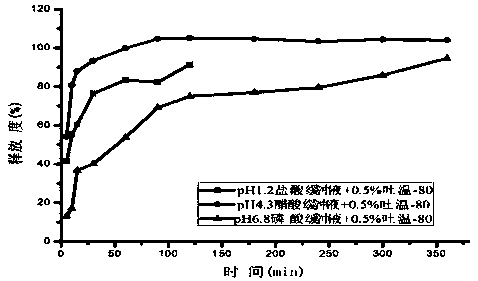

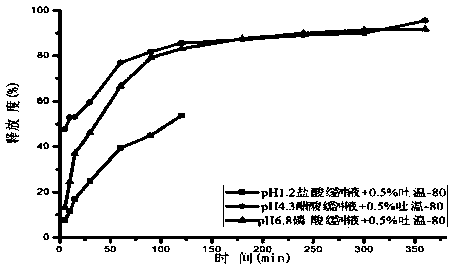

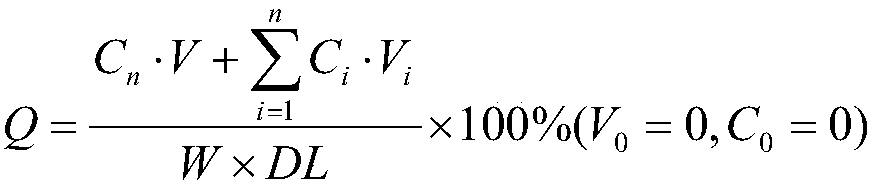

Image

Examples

Embodiment 1

[0049] Prepare curcumin solid dispersion according to the following steps:

[0050] S1. Weigh 10.0% curcumin bulk drug, 25.0% hydroxypropyl-β-cyclodextrin, 10.0% polyethylene glycol 6000, 30.0% polyethylene monostearate, 10% Tween-80, peppermint Oil 10.0%; polyethylene glycol 6000, hydroxypropyl-β-cyclodextrin was heated and melted at 90°C to obtain a mixture.

[0051] S2. After dissolving the curcumin raw material in medicinal ethanol, add polyethylene monostearate in the proportion described in S1, fully oscillate and mix evenly to prepare the mixture;

[0052] S3 adding the mixture obtained in S2 to the mixture described in step S1, stirring evenly to combine the curcumin molecules with the carrier to obtain the mixture;

[0053] S4. Add peppermint oil to the mixture C obtained in step S3, and stir evenly at a heat preservation temperature of 40° C. to obtain a mixture;

[0054] S5. Cool the mixture in step S4 to 20°C-30°C, spray and granulate the mixture in a fluidized b...

Embodiment 2

[0057] S1. Weigh 10% of curcumin crude drug according to the proportion, 20.0% of phospholipid, 20.0% of polyethylene glycol 6000, 40.0% of polyoxyethylene castor oil, 10% of clove oil; get a mixture;

[0058] S2. After dissolving the curcumin raw material with ethanol, add the polyoxyethylene castor oil of the ratio described in S1, fully shake and mix to prepare the mixture;

[0059] S3 adding the mixture obtained in S2 to the mixture described in step S1, stirring evenly to combine the curcumin molecules with the carrier to obtain the mixture;

[0060] S4. Add clove oil to the mixture C obtained in step S3, and stir evenly at a heat preservation temperature of 40° C. to obtain a mixture;

[0061] S5. Cool the mixture in step S4 to 20°C to 30°C, spray and granulate the mixture in a fluidized bed; the temperature of the fluidizing air is 20°C, and the linear velocity is 80 m / s;

[0062] S6. Cool the granules described in step S5, and collect granules with a particle size be...

Embodiment 3

[0064] S1. Weigh 10.0% curcumin crude drug according to the proportion, polyethylene glycol 6000 30.0%, hydroxypropyl-β-cyclodextrin 25.0%, Tween-80 25.0%, sorbitol 10.0%; polyethylene glycol 6000 , Hydroxypropyl-β-cyclodextrin was heated and melted at 90°C to obtain a mixture;

[0065] S2. After dissolving the curcumin raw material in ethanol, add Tween-80 in the proportion described in S1, fully oscillate and mix evenly to prepare the mixture;

[0066] S3 adding the mixture obtained in S2 to the mixture described in step S1, stirring evenly to combine the curcumin molecules with the carrier to obtain the mixture;

[0067] S4. Adding sorbitol to the mixture C obtained in step S3, and stirring evenly at a heat preservation temperature of 40° C. to obtain the mixture;

[0068] S5. Cool the mixture in step S4 to 20°C-30°C, spray and granulate the mixture in a fluidized bed; the temperature of the fluidizing air is 20°C, and the linear velocity is 135 m / s;

[0069] S6. Cool the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com