Composite filler and preparation method thereof

A composite filler and composite matrix technology, which is applied in the preparation methods of peptides, chemical instruments and methods, ion exchange, etc., can solve the problems of affecting the loading of the filler and the flow rate, slow flow rate affecting purification efficiency, and low protein purification efficiency. Improve purification efficiency and effect, stable physical and chemical properties, and improve separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

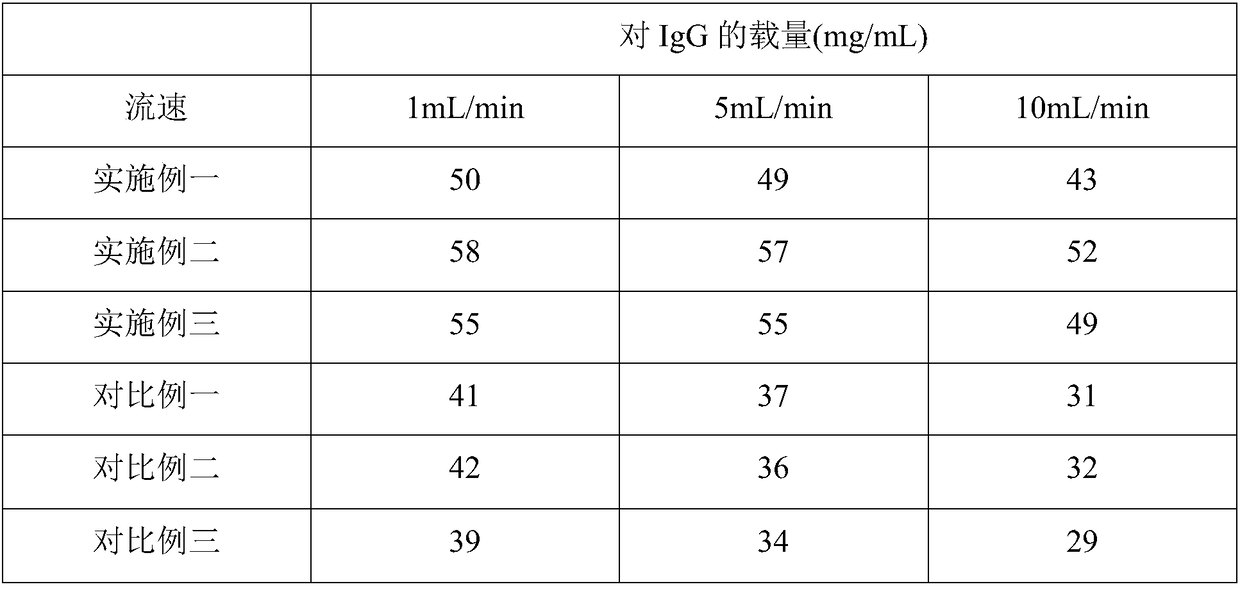

Examples

Embodiment 1

[0053] Preparation of composite filler:

[0054] (1) Preparation of composite base balls: Take 100g of cellulose, add it to a 1L three-necked flask, add 200ml of deionized water, put the three-necked flask into a constant temperature water bath, and stir at 40°C and 200rpm for 0.5h; The temperature of the pot is raised to 92°C, add 17g of agarose to the three-necked flask, and stir for 2 hours; continue to add 1g of disodium hydrogen phosphate and 1g of sodium sulfate, so that the pH of the mixture is 9-10; take the agarose and cellulose mixture Measure the viscosity with a viscometer. When the viscosity is 600-800 Pa.s, stop heating and cool down the agarose-cellulose mixture to 50°C. Take 100ml of toluene and put it into another 500ml three-necked flask, put the three-necked flask into a water bath, stir at 50°C and 100rpm for 0.5h, add 1ml of Span 80, and continue stirring for 1h. Slowly pour the cooled agarose cellulose mixture into the toluene Span 80 mixture, and contin...

Embodiment 2

[0060] Preparation of composite filler:

[0061] (1) Preparation of composite base balls: Take 100g of cellulose, add it to a 1L three-necked flask, add 300ml of deionized water, put the three-necked flask into a constant temperature water bath, and stir at 50°C and 300rpm for 1 hour; put the water bath The temperature of the temperature rises to 98°C, add 20g of agarose to the three-necked flask, and stir for 3 hours; continue to add 1.5g of disodium hydrogen phosphate and 1.5g of sodium sulfate, so that the pH of the mixture is 9-10; take the agarose cellulose and mix Measure the viscosity of the liquid with a viscometer. When the viscosity is 600-800 Pa.s, stop heating and cool down the agarose-cellulose mixture to 60°C. Take 300ml of toluene and put it into another 500ml three-necked flask, put the three-necked flask into a water bath, stir at 60°C and 150rpm for 1h, add 3ml of Span 80, and continue stirring for 2h. Slowly pour the cooled agarose cellulose mixture into th...

Embodiment 3

[0067] Preparation of composite filler:

[0068] (1) Preparation of composite base balls: Take 100g of cellulose, add it to a 1L three-necked flask, add 400ml of deionized water, put the three-necked flask into a constant temperature water bath, and stir at 60°C and 200rpm for 2 hours; put the water bath The temperature of the temperature rises to 100°C, add 25g of agarose to the three-necked flask, and stir for 4 hours; continue to add 1.5g of disodium hydrogen phosphate and 1.5g of sodium sulfate, so that the pH of the mixture is 9 to 10; take the agarose cellulose and mix Measure the viscosity of the liquid with a viscometer. When the viscosity is 600-800 Pa.s, stop heating and cool down the agarose-cellulose mixture to 70°C. Put 600ml of toluene into another 1L three-necked flask, put the three-necked flask into a water bath, stir at 60°C and 150rpm for 1h, add 3ml of Span 80, and continue stirring for 3h. Slowly pour the cooled agarose cellulose mixture into the toluene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com