Preparation method of n-alkane hydroisomerization catalyst

A technology for hydroisomerization and n-paraffin, which is applied in the field of hydrogenation catalyst preparation, can solve the problems of secondary destruction of active metals and supports, catalyst catalytic performance decline, water and energy consumption, etc., and achieves easy control and convenient operation. , the effect of maintaining catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method for a n-alkane hydroisomerization catalyst, specifically comprising the following steps:

[0027] (1) Roast the molecular sieve at 550 °C for 4 hours in the air atmosphere of the muffle furnace to remove the residual template agent;

[0028] (2) Mix the molecular sieve treated in step (1) with the binder according to the mass ratio of (60% - 80%): (20% - 40%) on a dry basis for 15 minutes until uniform, and the concentration is 0.5 ~ 5 wt % nitric acid and deionized water, kneaded evenly, extruded into a cylindrical carrier with a diameter of 2.0 mm, dried at 120 °C for 24 hours at room temperature, and then calcined in air atmosphere; the calcined carrier was heated at 120 ℃ drying for 12 hours, cooled to room temperature;

[0029] (3) Add Group VIII metal salts to 2 wt% nitric acid, stir until the solids are completely dissolved, and obtain an impregnation solution;

[0030] (4) Immerse the carrier obtained in step (2) in the impregnating soluti...

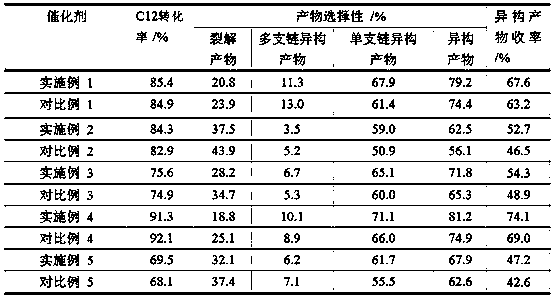

Embodiment 1

[0037] (1) The SAPO-11 molecular sieve was calcined at 550 °C for 4 hours under the air atmosphere of the muffle furnace to remove the residual template agent;

[0038](2) Mix the SAPO-11 molecular sieve treated in step (1) and pseudo-boehmite at a dry basis mass ratio of 75%: 25% for 15 minutes until uniform, and add nitric acid and deionized water with a concentration of 3 wt%. , kneaded evenly, extruded into a cylindrical carrier with a diameter of 2.0 mm, dried at 120 °C for 24 hours at room temperature, and then roasted in air atmosphere; the roasted carrier was dried at 120 °C for 12 hours, Cool to room temperature;

[0039] (3) will H 2 PtCl 6 The metal salt was added to 2 wt% nitric acid and stirred until the solid was completely dissolved to obtain a Pt-containing impregnating solution;

[0040] (4) Using an equal-volume impregnation method, impregnate the carrier obtained in step (2) into the Pt-containing impregnation solution obtained in step (3), and after impr...

Embodiment 2

[0044] (1) The SAPO-11 molecular sieve was calcined at 550 °C for 4 hours under the air atmosphere of the muffle furnace to remove the residual template agent;

[0045] (2) Mix the SAPO-11 molecular sieve treated in step (1) and pseudo-boehmite at a dry basis mass ratio of 75%: 25% for 15 minutes until uniform, and add nitric acid and deionized water with a concentration of 3 wt%. , kneaded evenly, extruded into a cylindrical carrier with a diameter of 2.0 mm, dried at 120 °C for 24 hours at room temperature, and then roasted in air atmosphere; the roasted carrier was dried at 120 °C for 12 hours, Cool to room temperature;

[0046] (3) will H 2 PtBr 6 The metal salt was added to 2 wt% nitric acid and stirred until the solid was completely dissolved to obtain a Pt-containing impregnating solution;

[0047] (4) Using an equal-volume impregnation method, impregnate the carrier obtained in step (2) into the Pt-containing impregnation solution obtained in step (3), and after imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com