Automatic surfacing welding machine and control system for inner and outer walls of wear ring

A technology of automatic surfacing and inner and outer walls, applied in the direction of manufacturing tools, welding rod characteristics, welding equipment, etc., can solve the problems of high technical level requirements for welders, difficulty in welding quality, uneven thickness of surfacing layer, etc., to achieve favorable Labor protection, stable welding quality, and the effects of reducing heat radiation and light radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

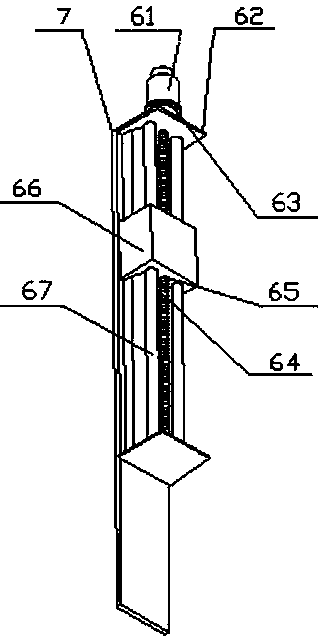

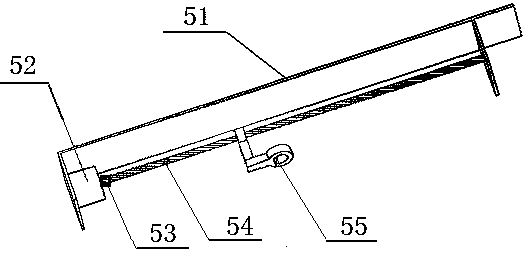

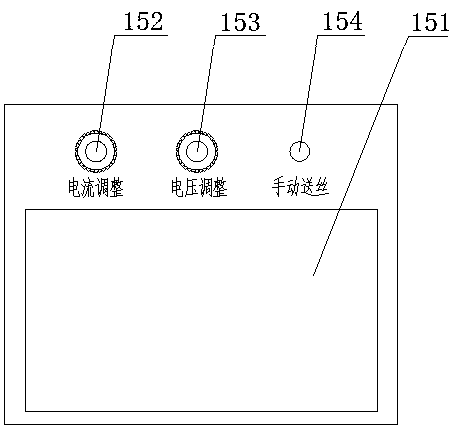

[0019] Such as figure 1 As shown, the automatic surfacing welding machine for the inner and outer walls of the wear-resistant ring includes an electric control box 1, a spindle box 2, a quick positioning three-jaw chuck 3, a welding torch 4, a horizontal feeding mechanism 5, a vertical lifting mechanism 6, a column 7, and a wire feeding mechanism 8. Welding wire 9, welding power source 10, base 14, touch screen 15, wherein, electric control box 1, spindle box 2 and column 7 are all installed on the base 14. The electric control box 1 is arranged on the left side of the spindle box 2, and a stepping motor controller 71 and a frequency converter 72 are arranged inside it. The motor controller 71 receives instructions input from the touch screen 15 to control the X-axis step of the horizontal feed mechanism 5. The motor 52 and the Y-axis stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com