Automatic radix adenophorae slicing machine and slicing method thereof

A technology of slicer and sand ginseng, which is applied in metal processing and other directions, can solve the problems of complex operation, high labor intensity, and low efficiency, and achieve the effects of simple control method, space saving, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

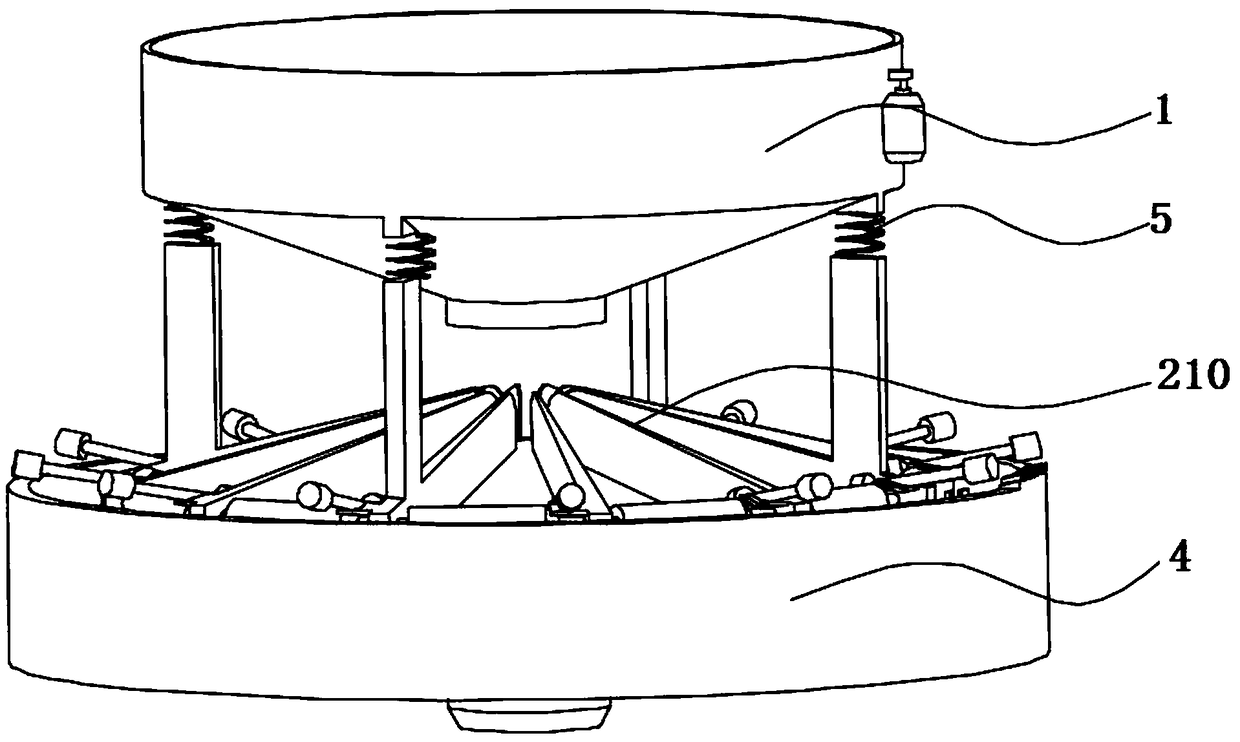

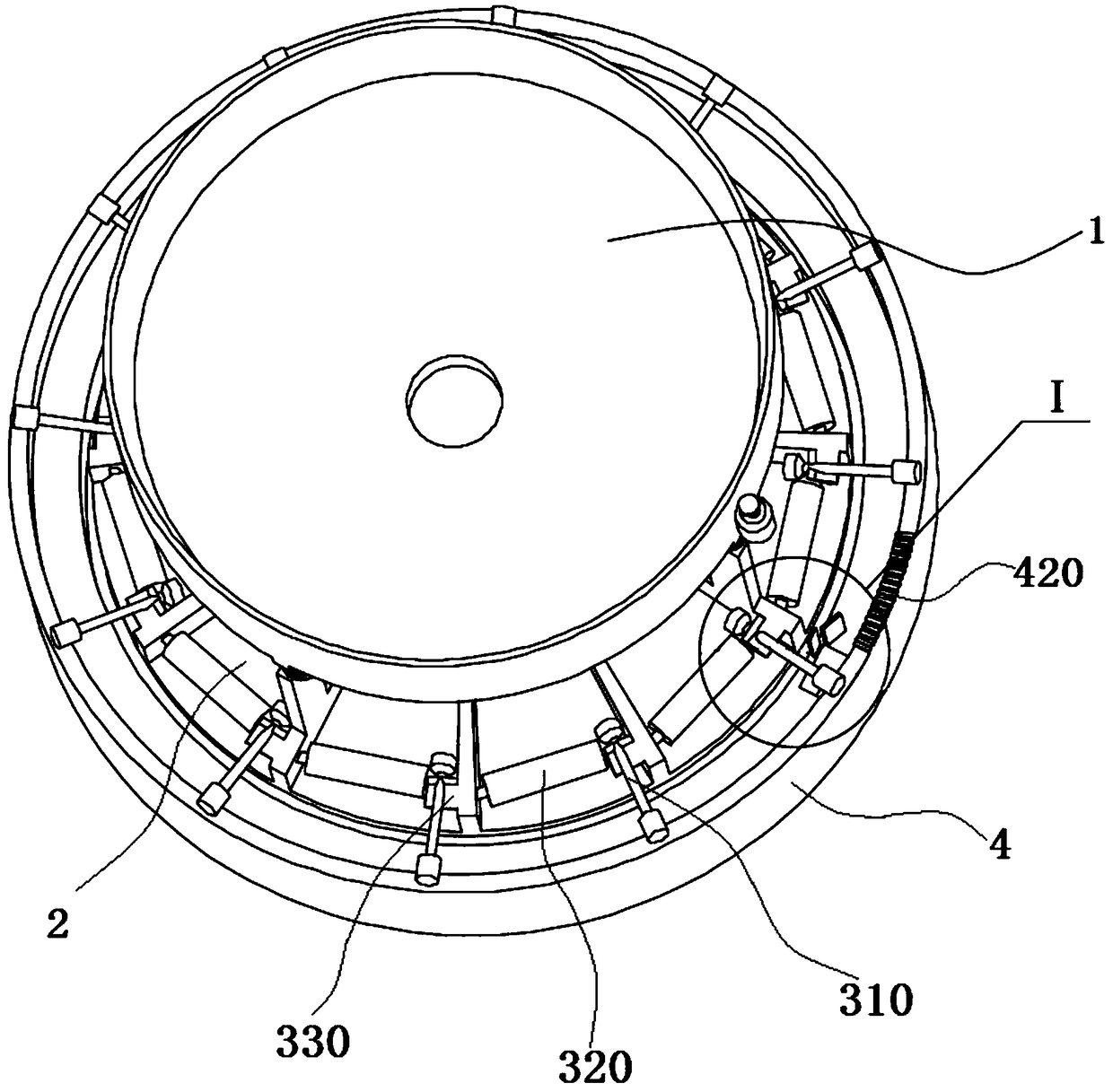

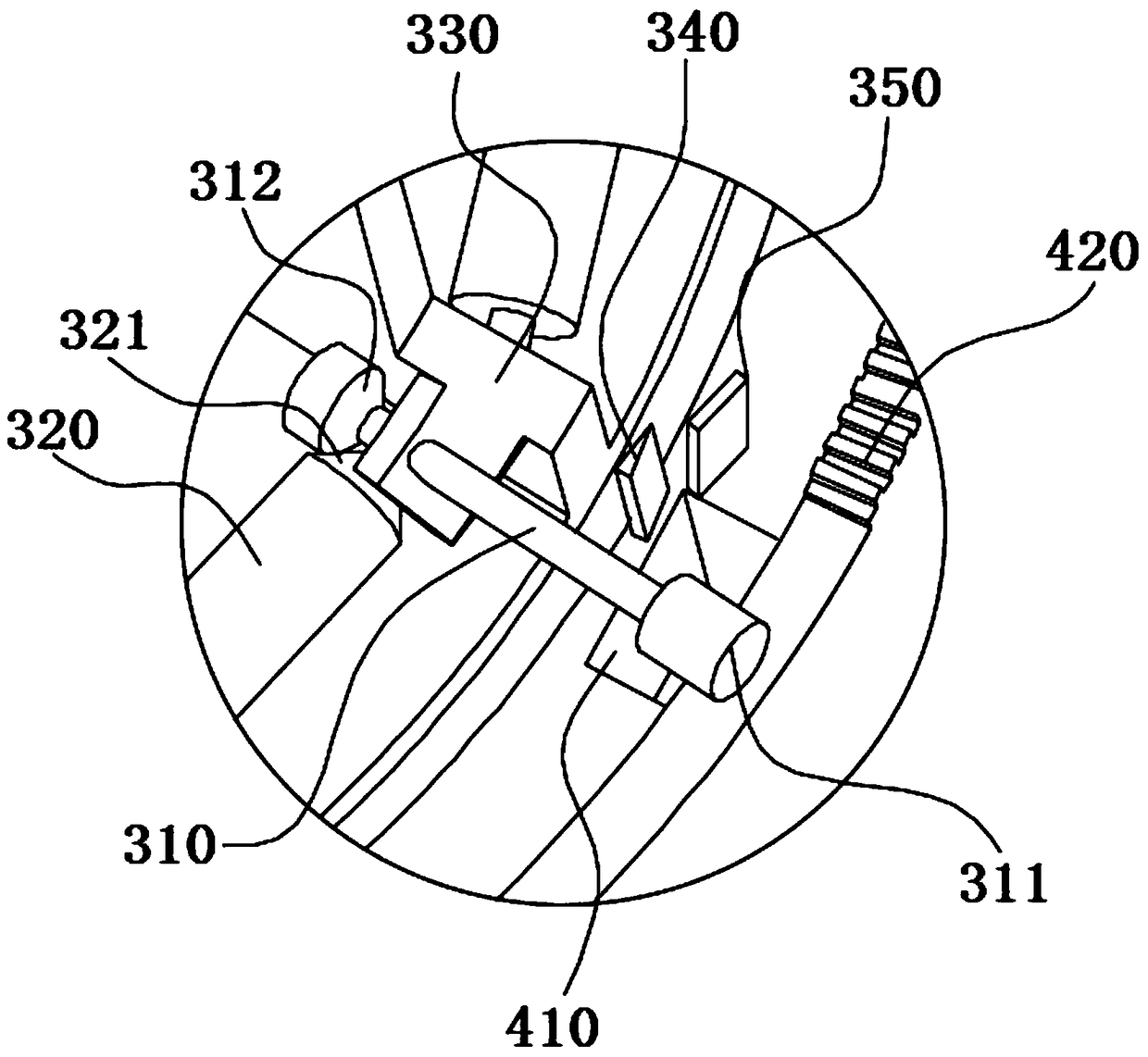

[0048] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, an automatic slicing machine for sand ginseng includes a hopper 1, a distribution tray 2, a slicing device 3, a material receiving baffle 4 and a motor 7. The hopper 1 is equipped with a vibrating motor 6, and the hopper 1 is fixedly connected to the top of the distribution tray 2 through 4 columns, and a damping spring 5 is arranged between the column and the hopper 1; the distribution tray 2 is Conical shape with the tip pointing upwards, the surface is fixedly connected with several side baffles 210 along the direction of the busbar of the distribution tray 2, and a guiding channel for the ginseng to the slicing device 3 is formed between each pair of side baffles 210. The disc 2 is evenly provided with 12 slicing devices 3 along the circumferential direction; the material receiving baffle 4 is barrel-shaped, and is arranged around the bottom of the material distribution plate 2, and the inner side o...

Embodiment 2

[0057] The structure of the sand ginseng automatic slicing machine of the present embodiment is basically the same as that in Embodiment 1, the difference is that a conical bottom plate and a discharge port 8 are arranged in the middle of the hopper 1, and the discharge port 8 is located at the bottom of the conical bottom plate. The middle part; the discharge port 8 includes a guide cone 810, a mounting ring 820 and a connecting plate 830, the mounting ring 820 is connected to the conical bottom plate, the guiding cone 810 is arranged inside the mounting ring 820, and the mounting ring 820 passes through the connecting plate 830 stick together.

[0058] The guide cone 810 and the installation ring 820 of the discharge port 8 of the slicer limit the sand ginseng to slide out from the discharge port along the guide cone 810 and fall onto the distribution tray 2. status is adjusted. Spread the Adenophora as far as possible in a single layer, and make the axial direction of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com