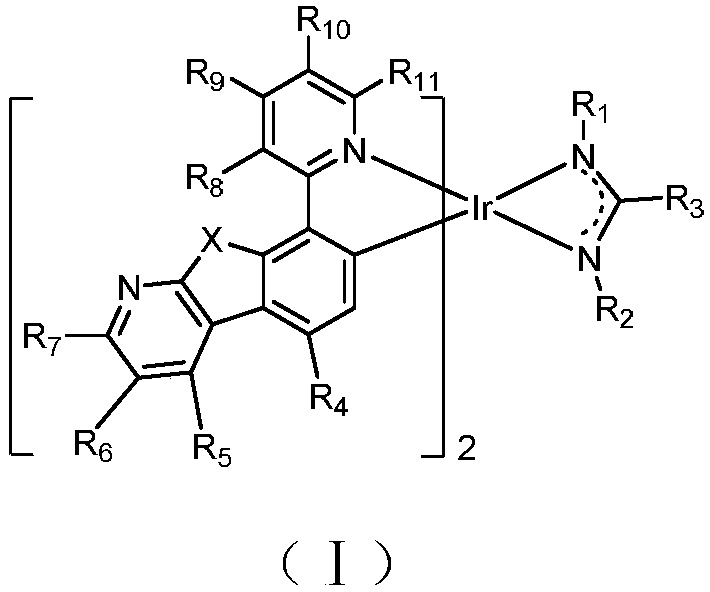

Iridium complex and organic light emitting device thereof

An organic light-emitting device, iridium complex technology, applied in the direction of light-emitting materials, organic chemistry, electric solid devices, etc., can solve the problems of high driving voltage, poor thermal stability, low luminous efficiency, etc., to achieve charge dispersion, improve stability, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

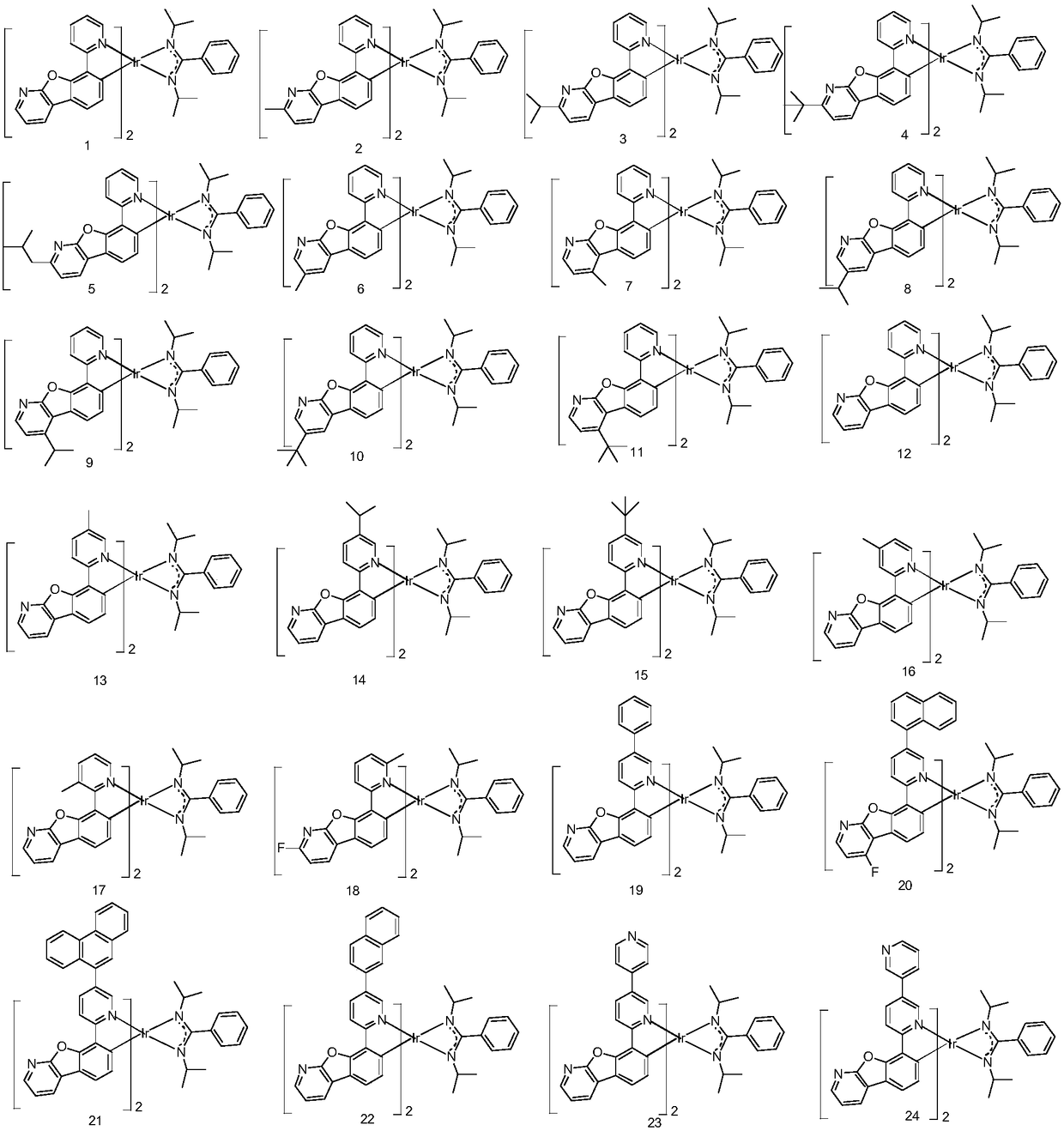

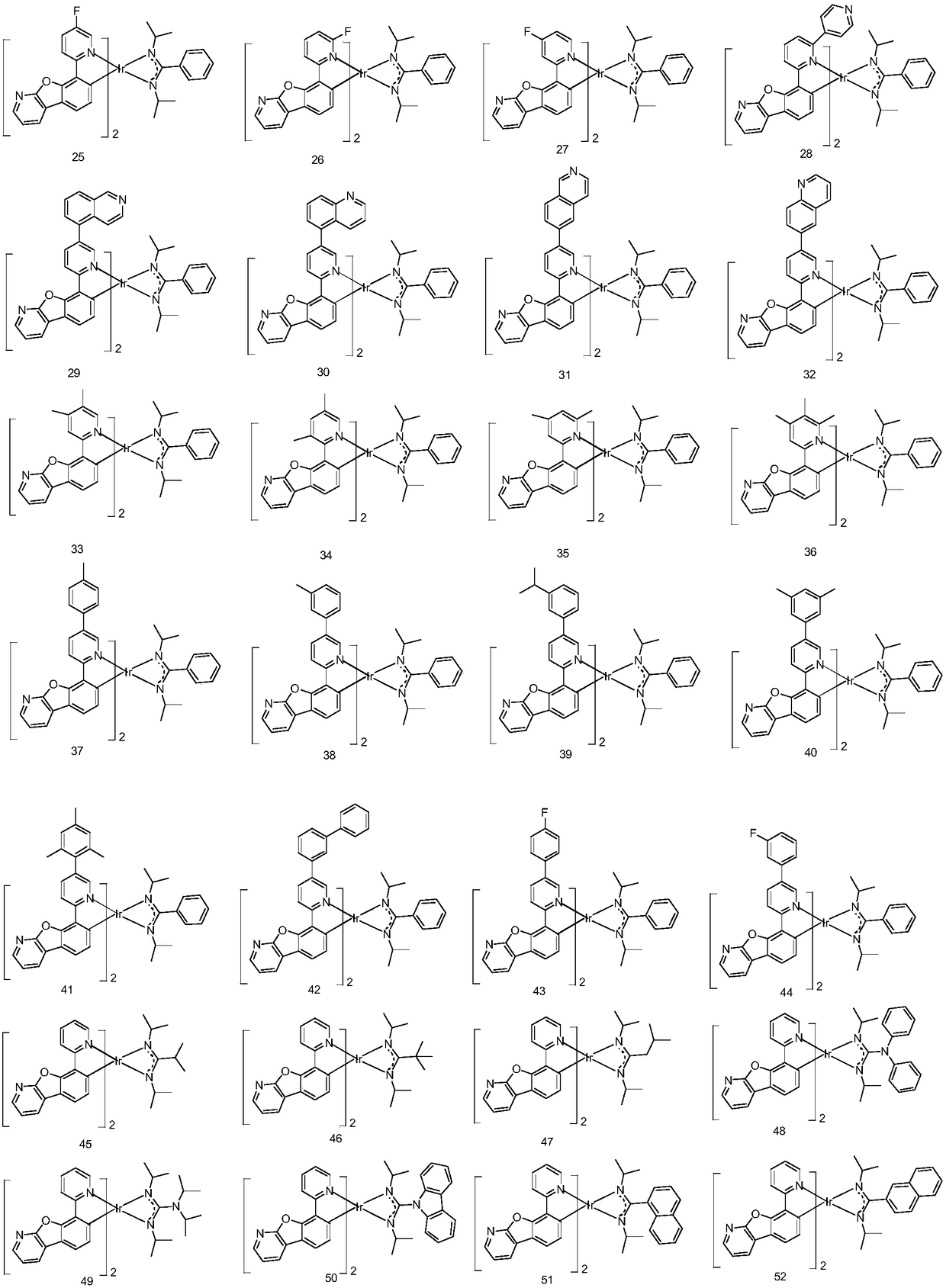

Examples

Embodiment 1

[0069] Embodiment 1: the preparation of compound 1

[0070]

[0071] Preparation of intermediate A1

[0072] Compound a1-2,6 dibromophenol (9.47g, 37.6mmol) was dissolved in tetrahydrofuran (140mL), and hexane solvent and 2.5M n-butyllithium (18mL, 45.1mmol) were added dropwise at -78°C, Stir for 1 hour. After slowly adding trimethyl borate (13 mL, 56.4 mmol) dropwise, stirred for 2 h. Then 2M hydrochloric acid was added dropwise to neutralize, and the product was extracted with ethyl acetate and water. Recrystallization from dichloromethane and hexane gave compound b1 (4.10 g, 47%). Weigh compound b1 (5.82g, 25.1mmol), compound c1 (7.13g, 25.1mmol), tetrakistriphenylphosphine palladium (11g, 10mmol) and potassium carbonate (8.42g, 60.9mmol), the reactant It was dissolved in a solvent of toluene (1 L) / EtOH (200 mL) / distilled water (200 mL), and heated at 90° C. for 2 hours. Compound d1 (12.50 g, 38 mmol) was weighed, KOH and Cu powder were added, and heated at 200° C. ...

Embodiment 2

[0080] Embodiment 2: the preparation of compound 6

[0081] The c1 in Example 1 was replaced by equimolar c6, and the other steps were the same as in Example 1 to obtain the target compound 6 (5.49 g, 29%).

[0082]

[0083] Mass Spectrum m / z: 915.31 (calculated: 915.30). Theoretical element content (%)C 47 h 42 IrN 6 o 2 : C, 61.69; H, 4.63; Ir, 21.00; N, 9.18; O, 3.50 The measured element content (%): C, 61.69; H, 4.62; The above results confirmed that the obtained product was the target product.

Embodiment 3

[0084] Embodiment 3: the preparation of compound 13

[0085] The f1 in Example 1 was replaced by equimolar f13, and the other steps were the same as in Example 1 to obtain the target compound 13 (5.49 g, 29%).

[0086]

[0087] Mass Spectrum m / z: 915.31 (calculated: 915.30). Theoretical element content (%)C 47 h 42 IrN 6 o 2 : C, 61.69; H, 4.63; Ir, 21.00; N, 9.18; O, 3.50 The measured element content (%): C, 61.69; H, 4.62; The above results confirmed that the obtained product was the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com