Oil stain-resistant thin film and preparation method thereof

A technology for anti-oil stains and thin films, which is applied to biocide-containing paints, anti-fouling/underwater coatings, coatings, etc. It can solve the problem of affecting wearing comfort and visual clarity, general anti-ultraviolet performance of films, and inconvenient cleaning of glasses lenses and other problems, to achieve the effect of strong anti-ultraviolet ability, good hydrophobic and oleophobic performance, and not easy to pollute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

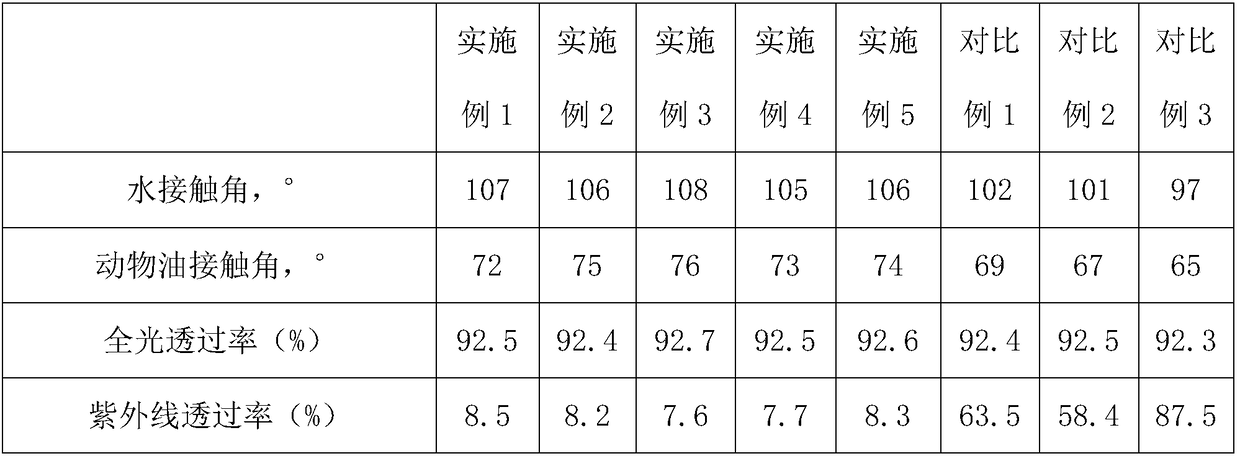

Examples

Embodiment 1

[0022] An oil stain-resistant film, comprising the following raw materials in parts by weight: 60 parts of bisphenol A type epoxy resin, 20 parts of polyacrylate, 5 parts of o-cresol novolac epoxy resin, 5 parts of polyethylene terephthalate, 3 parts of zinc oxide, 2 parts of aluminum iron polysilicate, 1 part of 2-hydroxy-4-methoxybenzophenone, 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole 1 part, 6 parts of organic solvent, 2 parts of leveling agent, 1 part of curing agent, 0.5 part of photoinitiator, 0.5 part of antioxidant.

[0023] Wherein, the organic solvent is made by mixing acetone, ethanol, and ethylene glycol ether in a weight ratio of 3:2:1.

[0024] Wherein, the leveling agent is polyether modified silicone oil.

[0025] In the present embodiment, the preparation method of the oil-resistant film, the steps are as follows:

[0026] 1) Mix bisphenol A type epoxy resin, polyacrylate, o-cresol novolac epoxy resin, and polyethylene terephthalate evenly, then add it...

Embodiment 2

[0032] An oil stain-resistant film, comprising the following raw materials in parts by weight: 65 parts of bisphenol A type epoxy resin, 22 parts of polyacrylate, 7 parts of o-cresol novolac epoxy resin, 6 parts of polyethylene terephthalate, 3.5 parts of zinc oxide, 2.5 parts of iron polysilicate aluminum, 1.8 parts of 2-hydroxy-4-methoxybenzophenone, 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole 1.8 parts, 9 parts of organic solvent, 3.5 parts of leveling agent, 2.5 parts of curing agent, 1.2 parts of photoinitiator, and 0.9 parts of antioxidant.

[0033] Wherein, the organic solvent is made by mixing acetone, ethanol, and ethylene glycol ether in a weight ratio of 3:2:1.

[0034] Wherein, the leveling agent is polyether modified silicone oil.

[0035] In the present embodiment, the preparation method of the oil-resistant film, the steps are as follows:

[0036] 1) Mix bisphenol A type epoxy resin, polyacrylate, o-cresol novolac epoxy resin, and polyethylene terephthalat...

Embodiment 3

[0042] An oil stain-resistant film, comprising the following raw materials in parts by weight: 70 parts of bisphenol A type epoxy resin, 25 parts of polyacrylate, 8 parts of o-cresol novolac epoxy resin, 7 parts of polyethylene terephthalate, 4 parts of zinc oxide, 3 parts of aluminum iron polysilicate, 1.5 parts of 2-hydroxy-4-methoxybenzophenone, 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole 1.5 parts, 8 parts of organic solvent, 3 parts of leveling agent, 2 parts of curing agent, 1 part of photoinitiator, 0.8 parts of antioxidant.

[0043] Wherein, the organic solvent is made by mixing acetone, ethanol, and ethylene glycol ether in a weight ratio of 3:2:1.

[0044] Wherein, the leveling agent is polyether modified silicone oil.

[0045] In the present embodiment, the preparation method of the oil-resistant film, the steps are as follows:

[0046] 1) Mix bisphenol A type epoxy resin, polyacrylate, o-cresol novolac epoxy resin, and polyethylene terephthalate evenly, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com