Oil refinery heating furnace smoke desulfurization induced draft fan PLC variable frequency speed adjusting control system

A technology of control system and frequency conversion speed regulation, which is applied in the direction of furnace control device, pump control, lighting and heating equipment, etc. It can solve the problems of manual adjustment of exhaust gas volume and air pollution, and achieve perfect functions, control of investment costs, and technical advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

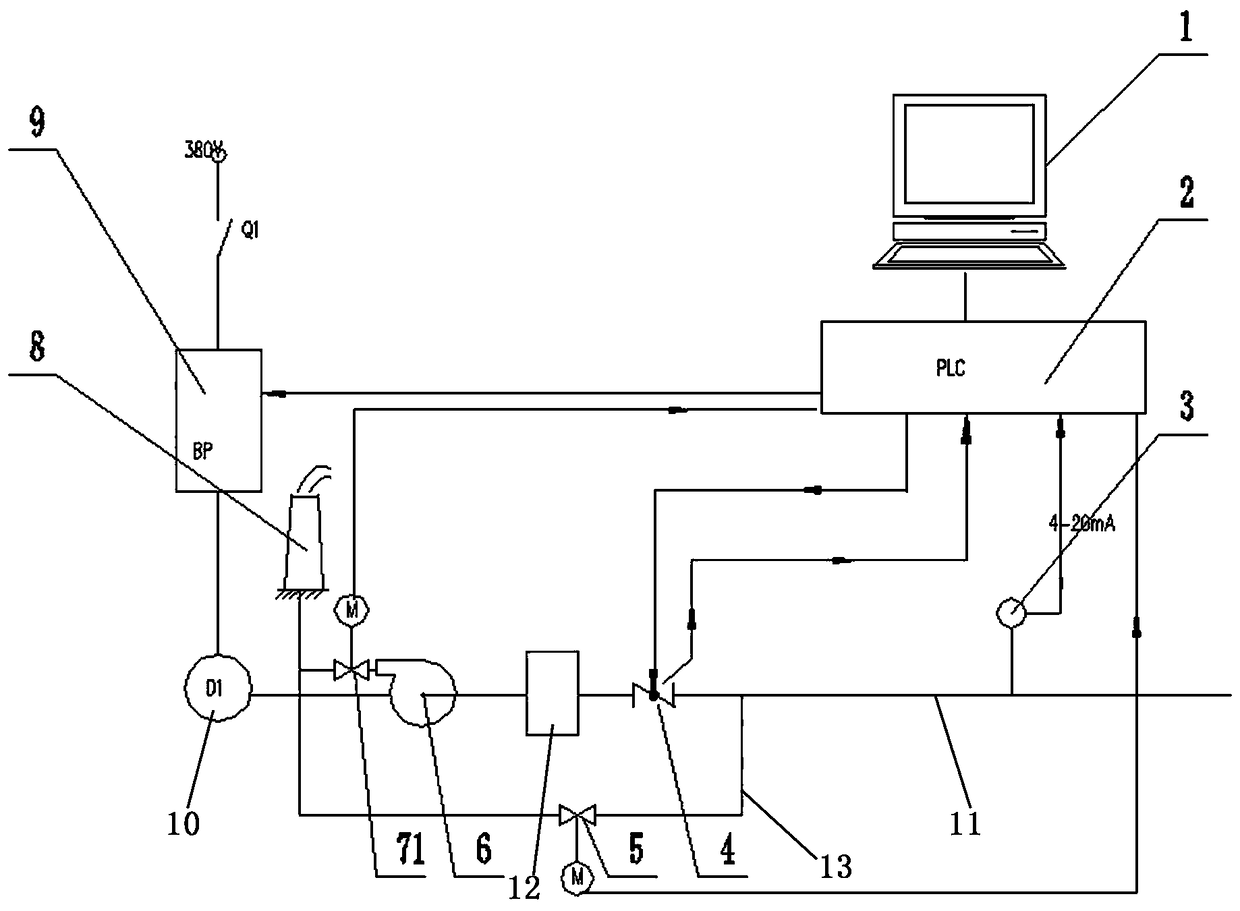

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0016] As shown in the figure, the flue gas desulfurization induced draft fan PLC control system of the refinery heating furnace of the present invention includes a chimney 8 and a flue gas pipeline 11, and the flue gas pipeline 11 is sequentially provided with a pressure transmitter 3 and an inlet electric butterfly valve 4 , the desulfurization device 12 and the desulfurization induced draft fan 6, the outlet of the desulfurization induced draft fan 6 is connected to the chimney 8 through a pipeline, the desulfurization induced draft fan 6 is connected to the motor 10, the motor 10 is connected to the frequency converter 9, and the frequency converter 9 receives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com