Sensitive material for detecting formaldehyde gas, preparation method and application thereof

A formaldehyde gas and sensitive material technology, applied in the field of sensors, can solve the problems of low detection limit, low working temperature and high sensitivity, and achieve the effects of simple steps, low working temperature and good response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

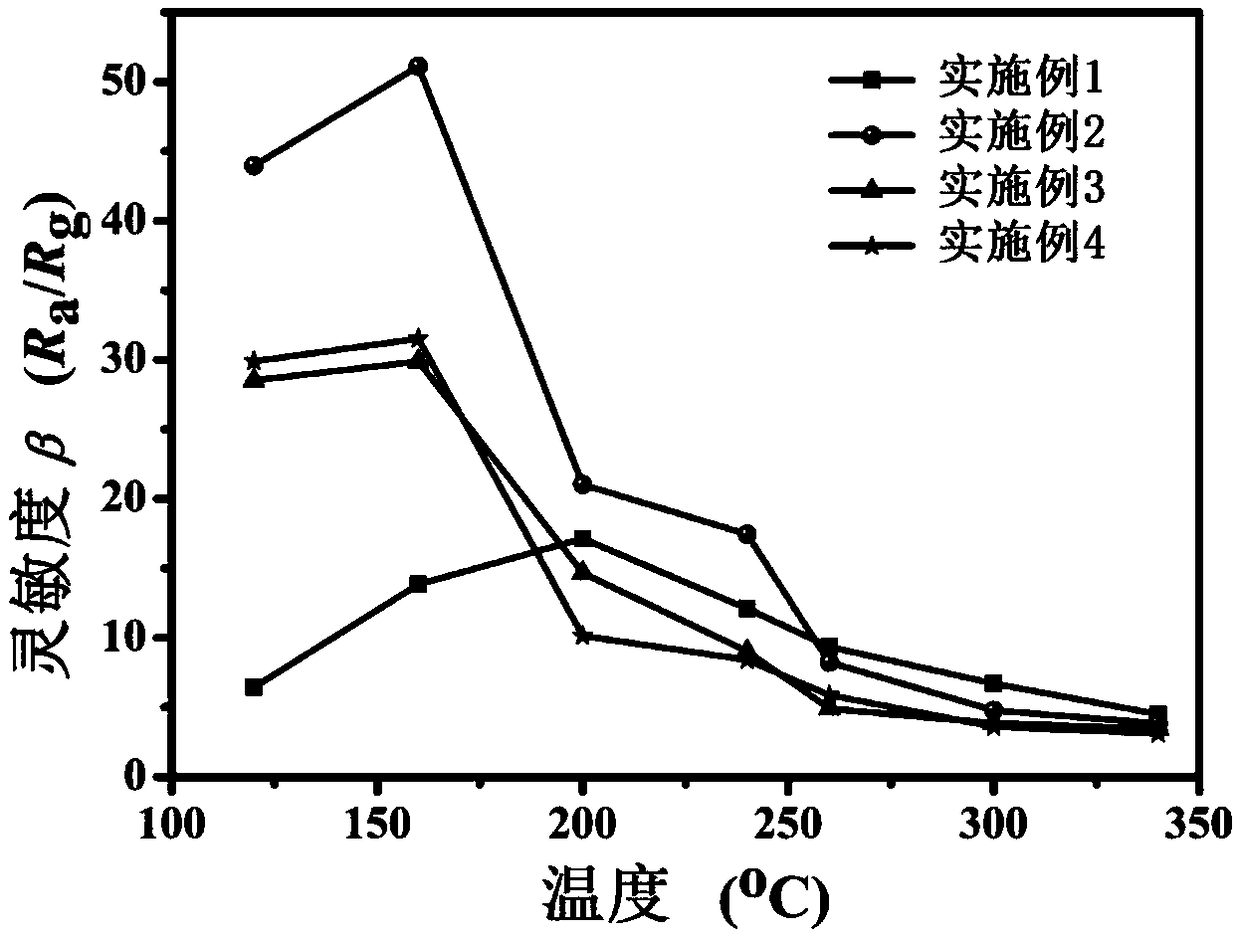

Embodiment 1

[0031] (1) Biological template pretreatment: peel off the white part of the inner layer of pomelo peel and cut it into many small pieces, wash with deionized and absolute ethanol, soak several times, ultrasonicate for 1h and dry at 60°C for 12h to obtain Dried pomelo peel bio template;

[0032] (2) Precursor solution preparation: under stirring at room temperature, 10mmol SnCl 4 ·5H 2 O was dissolved in a mixed solvent of 20mL deionized water and 20mL absolute ethanol;

[0033] (3) Add the 1g dry pomelo peel template obtained in step (1) into the mixed solution obtained in step (2) under stirring, and add 0.2404g urea (CO(NH 2 ) 2 ), the mixed solution was continuously stirred for 4h and ultrasonically treated for 30min;

[0034] (4) Transfer the mixed solution obtained in step (3) to a polytetrafluoroethylene lining, and keep it warm in a constant temperature drying oven at 150° C. for 12 hours;

[0035](5) Take it out and cool it down to room temperature. The obtained p...

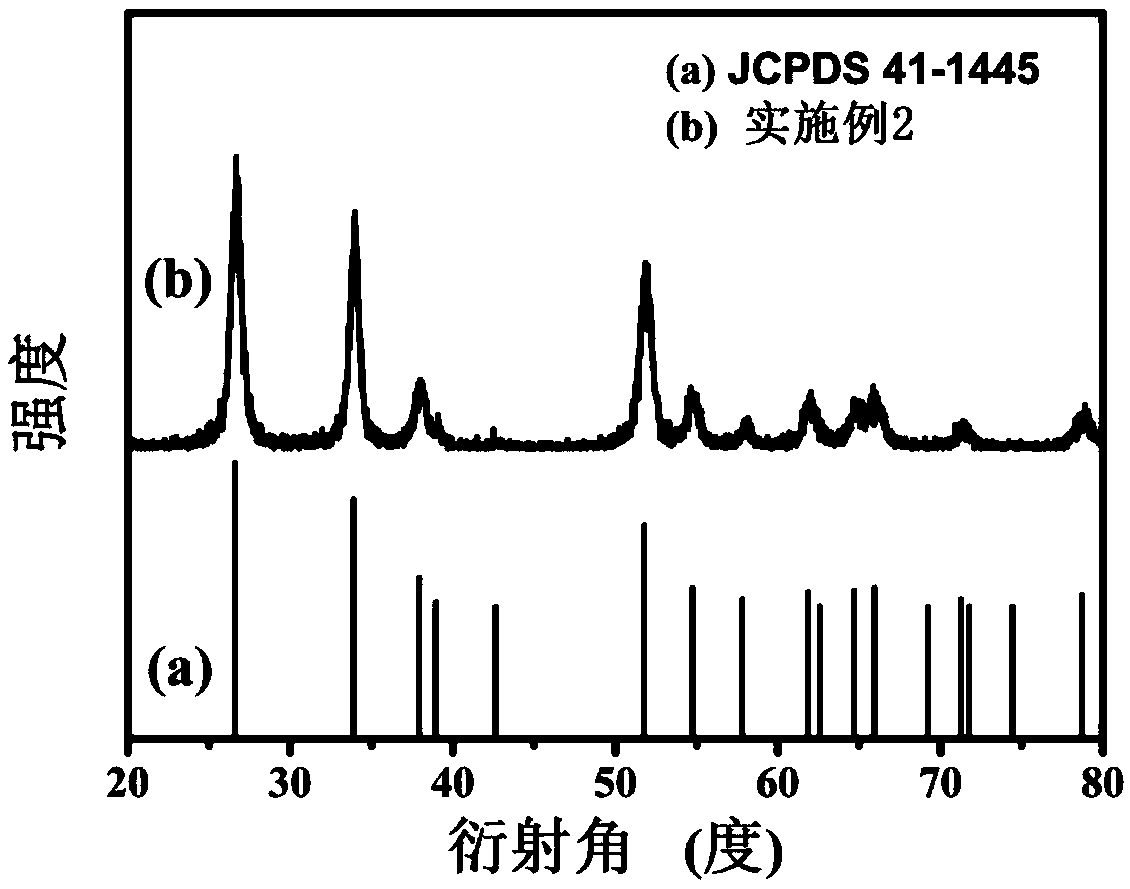

Embodiment 2

[0039] (1) Biological template pretreatment: peel off the white part of the inner layer of pomelo peel and cut it into many small pieces, wash with deionized and absolute ethanol, soak several times, ultrasonicate for 1h and dry at 60°C for 12h to obtain Dried pomelo peel bio template;

[0040] (2) Precursor solution preparation: under stirring at room temperature, 10mmol SnCl 4 ·5H 2 O was dissolved in a mixed solvent of 20mL deionized water and 20mL absolute ethanol; then adding a molar ratio of 5mol% in the above solution;

[0041] (3) Add the 1g dry pomelo peel template obtained in step (1) into the mixed solution obtained in step (2) under stirring, and add 0.2404g urea (CO(NH 2 ) 2 ), the mixed solution was continuously stirred for 4h and ultrasonically treated for 30min;

[0042] (4) Transfer the mixed solution obtained in step (3) to a polytetrafluoroethylene lining, and keep it warm in a constant temperature drying oven at 150° C. for 12 hours;

[0043] (5) Tak...

Embodiment 3

[0047] (1) Biological template pretreatment: peel off the white part of the inner layer of pomelo peel and cut it into many small pieces, wash with deionized and absolute ethanol, soak several times, ultrasonicate for 1h and dry at 60°C for 12h to obtain Dried pomelo peel bio template;

[0048] (2) Precursor solution preparation: under stirring at room temperature, 10mmol SnCl 4 ·5H 2 O is dissolved in the mixed solvent of 20mL deionized water and 20mL absolute ethanol; Adding molar ratio is 10mol% in the above solution;

[0049] (3) Add the 1g dry pomelo peel template obtained in step (1) into the mixed solution obtained in step (2) under stirring, and add 0.2404g urea (CO(NH 2 ) 2 ), the mixed solution was continuously stirred for 4h and ultrasonically treated for 30min;

[0050] (4) Transfer the mixed solution obtained in step (3) to a polytetrafluoroethylene lining, and keep it warm in a constant temperature drying oven at 150° C. for 12 hours;

[0051] (5) Take it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com