A kind of aramid fiber electrode and preparation method thereof

An aramid fiber and electrode technology, applied in the field of aramid fiber electrode and its preparation, can solve the problems of deterioration, coating layer peeling performance, poor adhesion, etc., and achieve high tensile strength, high energy density, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Dissolve 0.1g dopamine hydrochloride and 0.05g trishydrochloride in 100mL water to obtain solution A; dissolve 0.1g sodium hydroxide in 100mL water to obtain aqueous sodium hydroxide solution; use sodium hydroxide Adjust the pH value of solution A to 8.5 with an aqueous solution to obtain solution B; immerse 0.1 g of poly-p-phenylene terephthalamide fiber bundles in solution B, and vibrate at room temperature for 5 hours; after the reaction, the fibers are taken out, cleaned and Dried to obtain polydopamine-coated aramid fiber bundles;

[0064] (2) Dissolve 0.5g silver nitrate in 50mL water, add ammonia water drop by drop until the silver ammonia solution is clarified again, add 0.05g polyvinylpyrrolidone to obtain solution C; dissolve 1g glucose in 50mL water to obtain glucose aqueous solution; Add 0.1g polydopamine-coated aramid fiber bundles to the mixture, shake at room temperature, and add glucose aqueous solution dropwise, and continue to shake at room tempera...

Embodiment 2

[0070](1) Dissolve 0.2g of dopamine hydrochloride and 0.16g of trishydrochloride in 100mL of water to obtain solution A; dissolve 2g of sodium hydroxide in 100mL of water to obtain an aqueous solution of sodium hydroxide; Adjust the pH value of solution A to 8.5 to obtain solution B; immerse 0.5 g of poly-p-phenylene terephthalamide fiber bundles in solution B, shake at room temperature for 24 hours; take out the fibers after the reaction, wash and dry , to obtain polydopamine-coated aramid fiber bundles;

[0071] (2) Dissolve 1.5g silver nitrate in 50mL water, add ammonia water drop by drop until the silver ammonia solution is clarified again, add 0.25g polyvinylpyrrolidone to obtain solution C; dissolve 3g glucose in 50mL water to obtain glucose aqueous solution; Add 0.5g polydopamine-coated aramid fiber bundles to the mixture, shake at room temperature, and add glucose aqueous solution dropwise, and continue to shake at room temperature for 30 minutes; after the reaction, t...

Embodiment 3

[0078] (1)~(4) are consistent with embodiment two;

[0079] (5) Dissolve 0.85g of silver nitrate in 50mL of water to obtain an aqueous solution of silver nitrate; add 0.67g of pyrrole to 50mL of water, and then add 0.5g of aramid fiber bundles coated with carbon nanotubes and silver nanoparticles. Shake, while adding silver nitrate aqueous solution drop by drop, continue to shake at room temperature for 24h; After the reaction, the fiber is taken out, washed and dried to obtain aramid fiber bundles coated with polypyrrole, carbon nanotubes and silver nanoparticles. Aramid fiber electrodes.

[0080] (6)-(7) are consistent with the second embodiment, and an aramid fiber electrochemical capacitor is obtained.

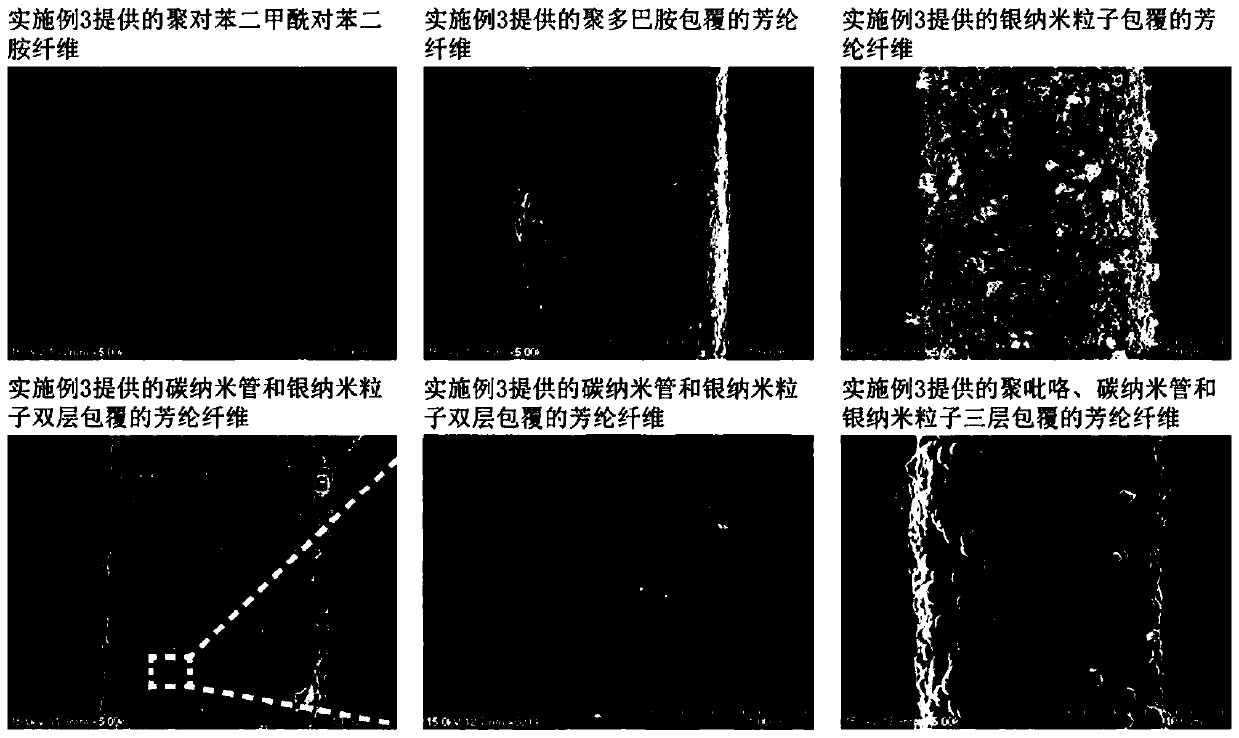

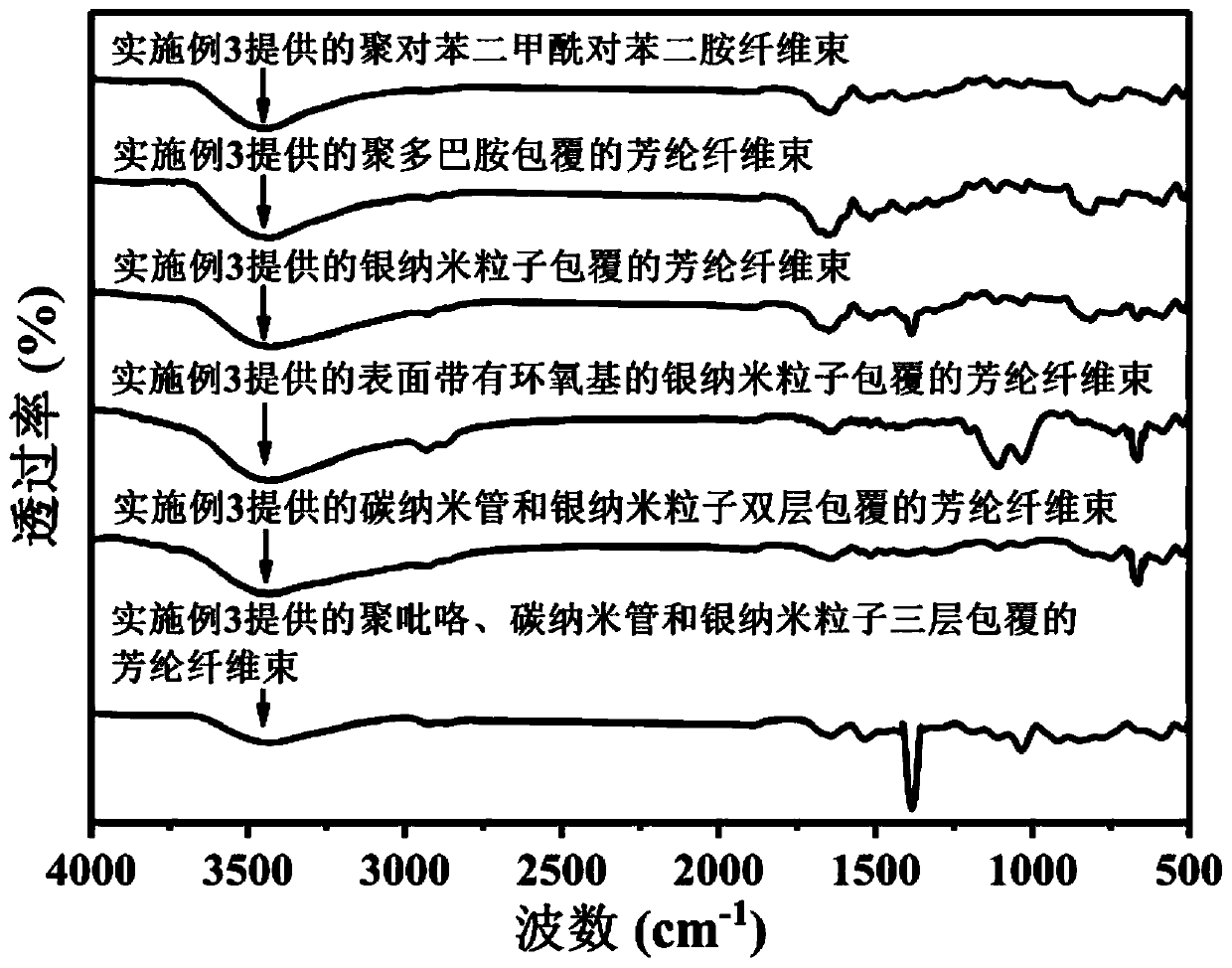

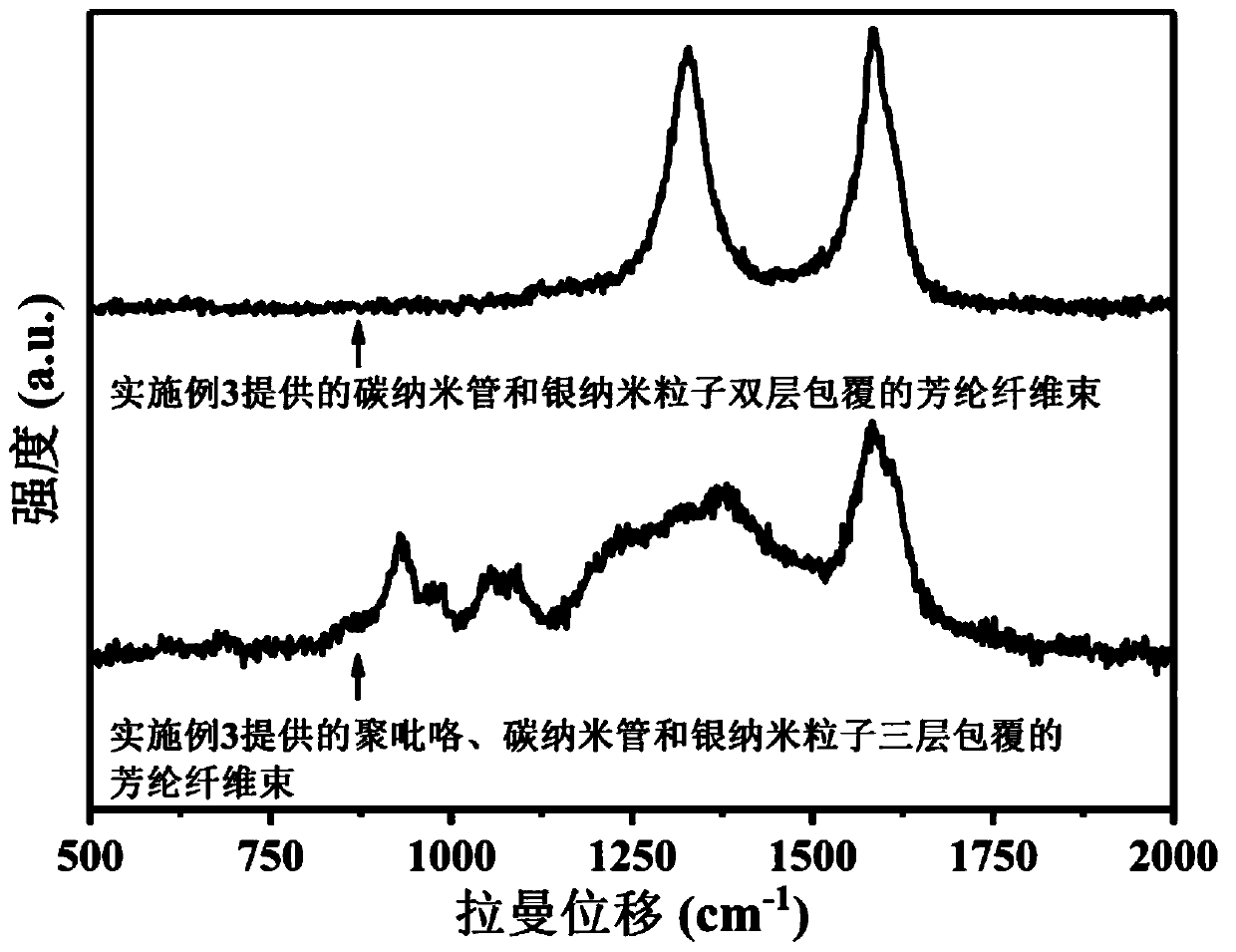

[0081] See attached figure 1 , which is the poly-p-phenylene terephthalamide fiber provided in Example 3 of the present invention, polydopamine-coated aramid fiber, silver nanoparticle-coated aramid fiber, carbon nanotube and silver nanoparticle double-layer Scanning el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Mass energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com