Ultraviolet light emitting diode with inverted structure

A technology of light-emitting diodes and diodes, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low light output efficiency and large turn-on voltage of ultraviolet LEDs, and achieve the effect of alleviating the effect of current congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

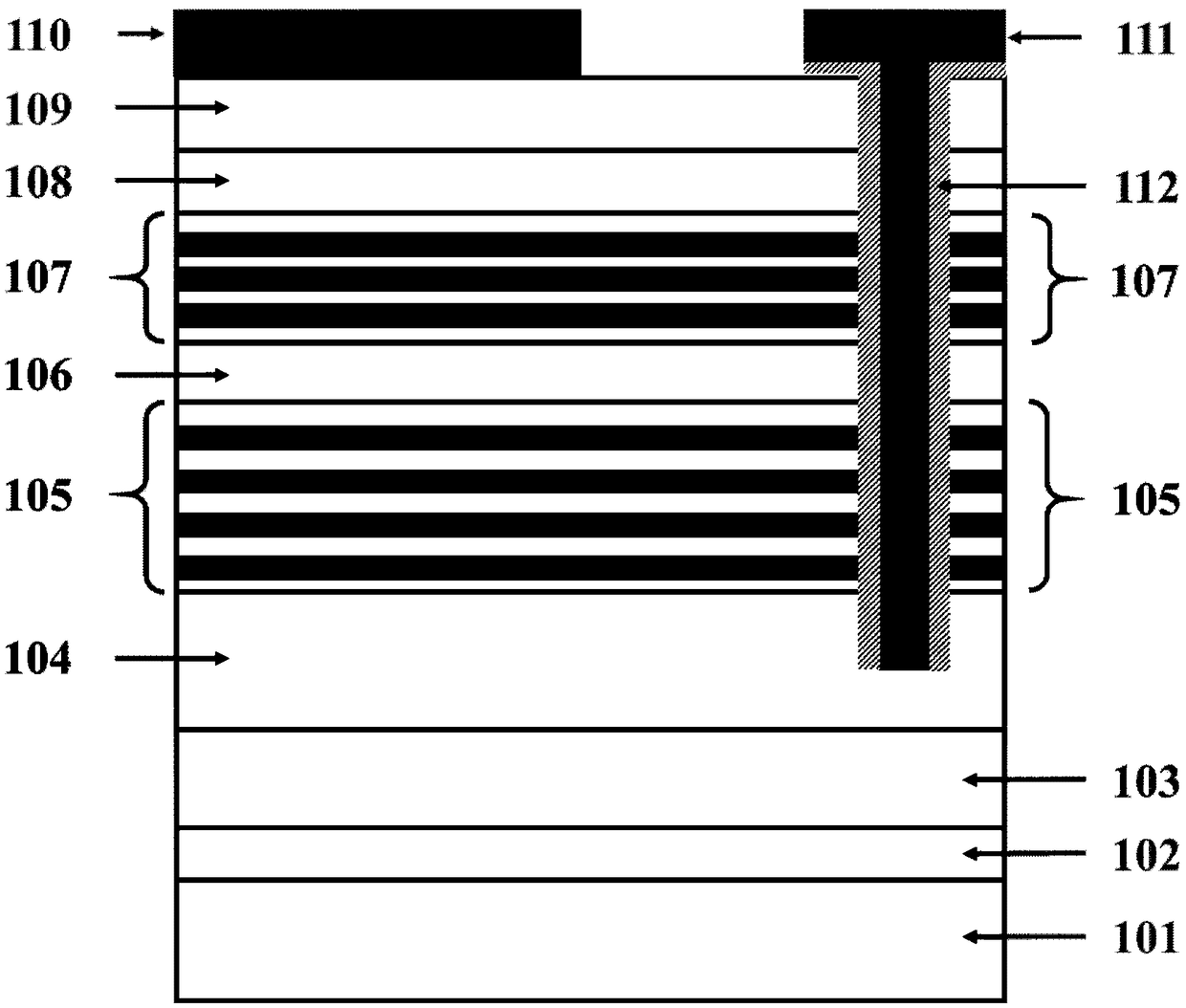

[0037] An ultraviolet light-emitting diode structure with a flip-chip structure, the diode includes a substrate 101, an AlN nucleation layer 102, an undoped AlN buffer layer 103, an n-type Al 0.5 Ga 1-0.5 N zone 104, Al 0.45 Ga 0.55 N-Al 0.6 Ga 0.4 N multi-quantum well active region 105, BN electron blocking layer 106, Al 0.6 Ga 0.4 N-BN Bragg mirror structure p-type region 107, heavily doped p-type GaN layer 108 and ITO conductive layer 109, on which a p-type ohmic electrode 110 is arranged in contact with, on the n-type Al 0.5 Ga 0.5 On the N region 104, an n-type ohmic electrode 111 is also arranged in contact, and the n-type ohmic electrode 111 penetrates other regions upwards and extends out of the ITO conductive layer 109, which is different from the n-type Al 0.5 Ga 0.5 An insulating layer 112 is disposed between regions other than the N region 104;

[0038] in:

[0039] The thickness of the BN electron blocking layer 106 is 3nm;

[0040] The Al 0.6 Ga 0.4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com