Bimetallic-organic-framework-based derived porous carbon/multi-wall carbon nanotube nano composite absorbing material and preparation method thereof

A technology of multi-wall carbon nanotubes and bimetallic nanometers, applied in the field of electromagnetic composite materials, to achieve the effects of wide frequency band, enhanced absorption capacity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

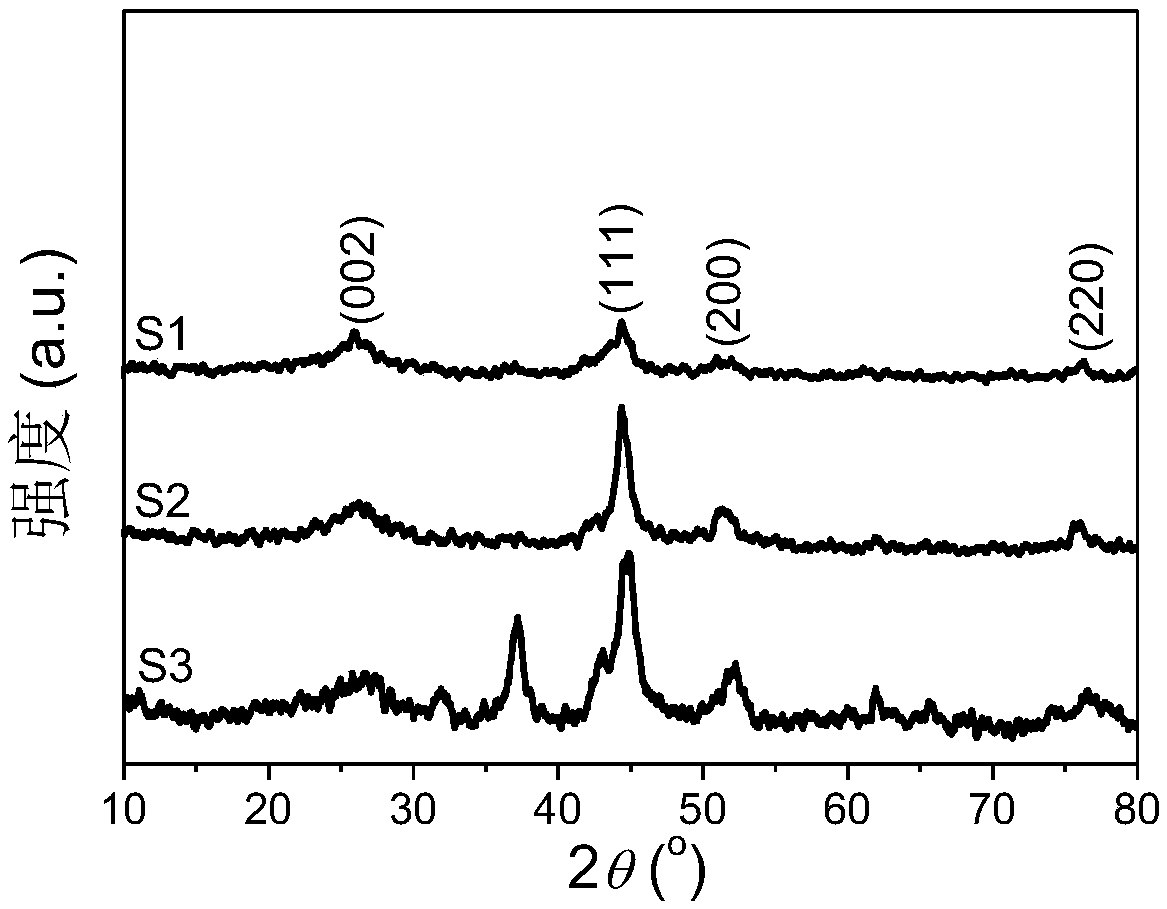

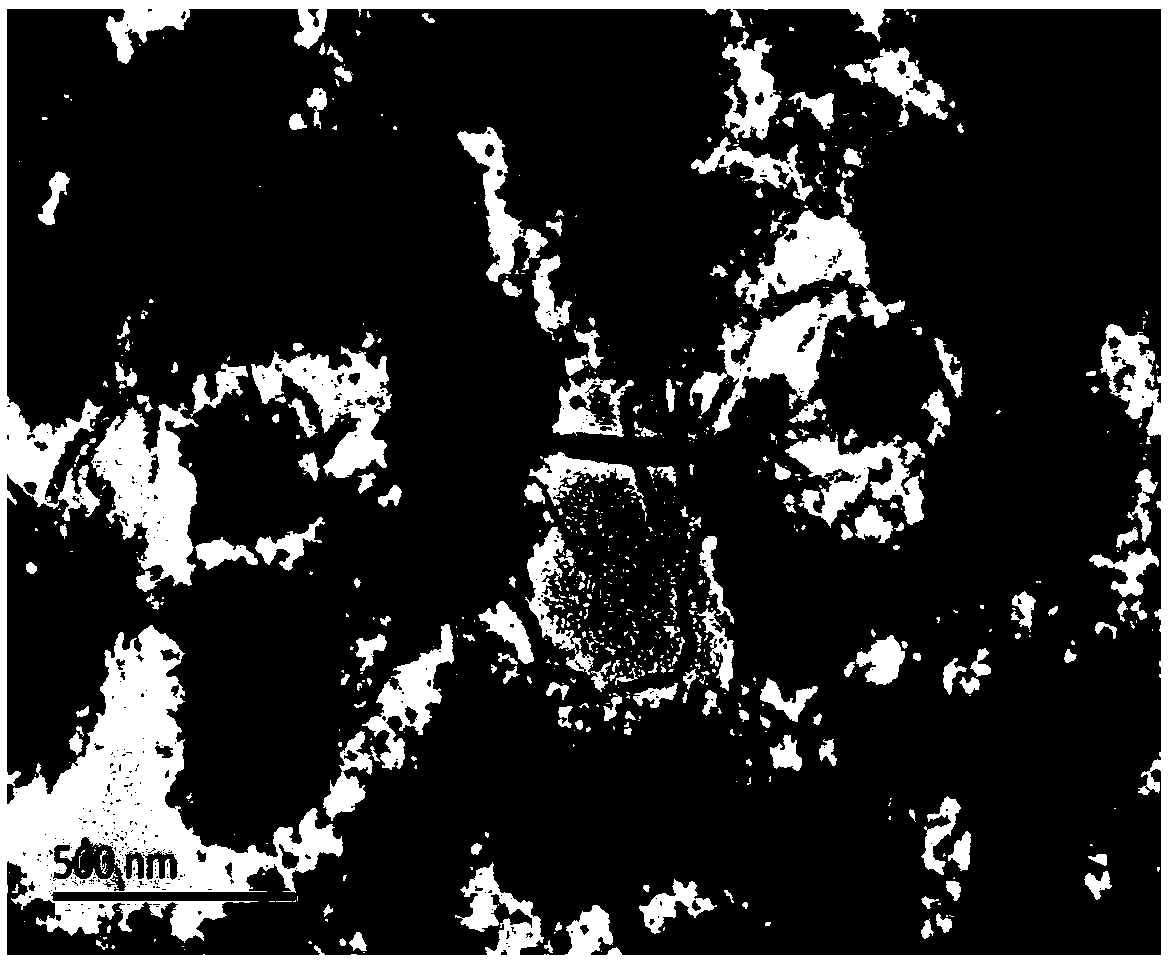

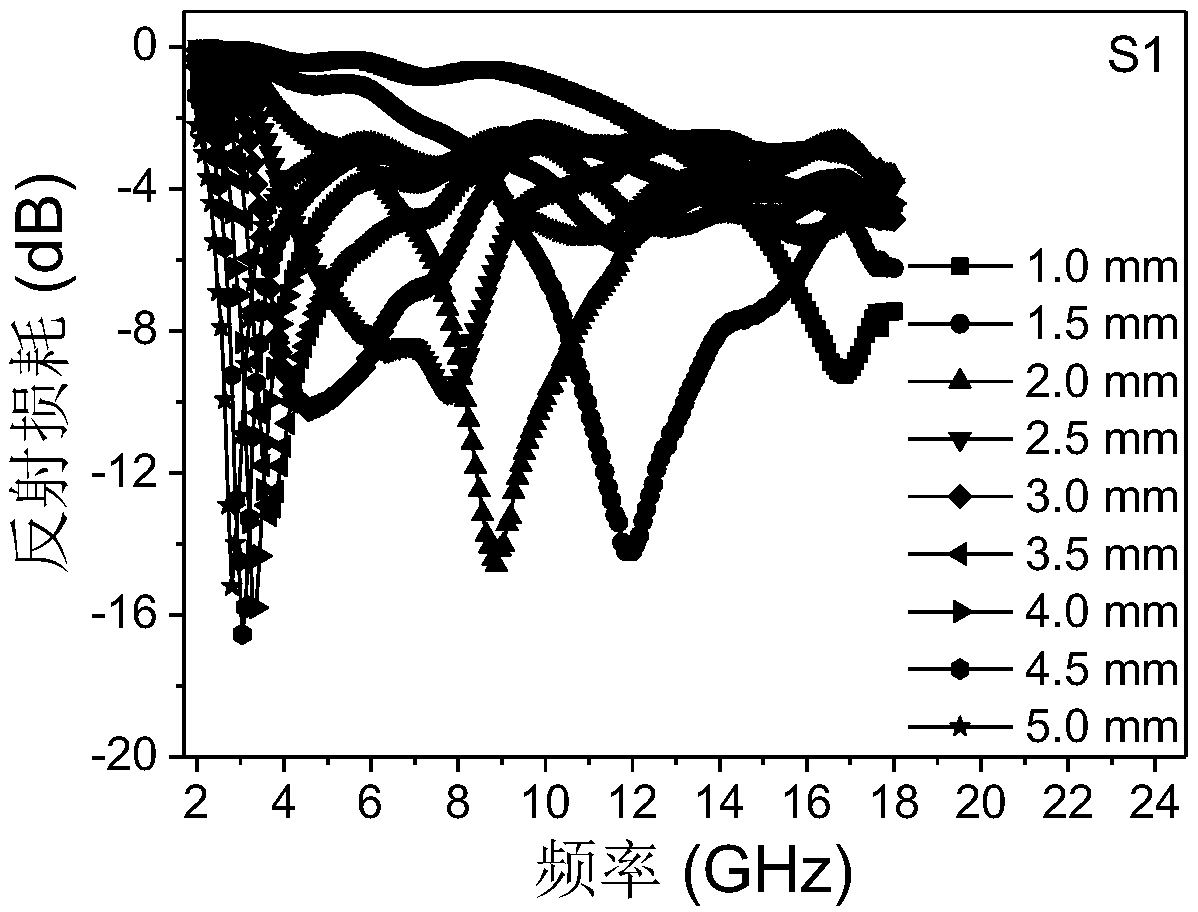

Embodiment 1

[0028] 1. Take a 250mL beaker, add 40mL methanol and 40mL absolute ethanol, mix well. Weigh 50mg MWCNTs, 1.74g Co(NO 3 ) 2 ·6H 2 O and 1.78g Zn(NO 3 ) 2 ·6H 2 O was sequentially added to methanol / absolute ethanol mixture. Stir vigorously for 30 minutes and then ultrasonically disperse for 30 minutes, alternately for 5 times, and control the stirring and ultrasonic time for 2.5 hours. The resulting mixture was labeled solution A.

[0029] 2. Take a 250mL beaker, add 40mL methanol and 40mL absolute ethanol, mix well. Then 3.94 g of 2-methylimidazole was added and stirred vigorously for 20 min. The resulting mixture was labeled solution B.

[0030] 3. Quickly add solution B into solution A under the condition of vigorous stirring, stir vigorously for 20 minutes, and leave the mixed dispersion to age for 24 hours.

[0031] 4. After aging, wash repeatedly with absolute ethanol by centrifugation for several times, collect the precipitate, put it into a vacuum drying oven, ...

Embodiment 2

[0035] 1. Take a 250mL beaker, add 40mL methanol and 40mL absolute ethanol, mix well. Weigh 25mg MWCNTs, 1.74g Co(NO 3 ) 2 ·6H 2 O and 1.78g Zn(NO 3 ) 2 ·6H 2 O was sequentially added to methanol / absolute ethanol mixture. Stir vigorously for 30 minutes and then ultrasonically disperse for 30 minutes, alternately for 5 times, and control the stirring and ultrasonic time for 2.5 hours. The resulting mixture was labeled solution A.

[0036] 2. Take a 250mL beaker, add 40mL methanol and 40mL absolute ethanol, mix well. Then 3.94 g of 2-methylimidazole was added and stirred vigorously for 20 min. The resulting mixture was labeled solution B.

[0037] 3. Quickly add solution B into solution A under the condition of vigorous stirring, stir vigorously for 20 minutes, and leave the mixed dispersion to age for 24 hours.

[0038] 4. After aging, wash repeatedly with absolute ethanol by centrifugation for several times, collect the precipitate, put it into a vacuum drying oven, ...

Embodiment 3

[0042] 1. Take a 250mL beaker, add 40mL methanol and 40mL absolute ethanol, mix well. Weigh 0mg MWCNTs, 1.74g Co(NO 3 ) 2 ·6H 2 O and 1.78g Zn(NO 3 ) 2 ·6H 2 O was sequentially added to methanol / absolute ethanol mixture. Stir vigorously for 30 minutes and then ultrasonically disperse for 30 minutes, alternately for 5 times, and control the stirring and ultrasonic time for 2.5 hours. The resulting mixture was labeled solution A.

[0043] 2. Take a 250mL beaker, add 40mL methanol and 40mL absolute ethanol, mix well. Then 3.94 g of 2-methylimidazole was added and stirred vigorously for 20 min. The resulting mixture was labeled solution B.

[0044] 3. Quickly add solution B into solution A under the condition of vigorous stirring, stir vigorously for 20 minutes, and leave the mixed dispersion to age for 24 hours.

[0045] 4. After aging, wash repeatedly with absolute ethanol by centrifugation for several times, collect the precipitate, put it into a vacuum drying oven, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com